Numerical control machining parameter adaptive fuzzy control rule optimization method

A technology of self-adaptive fuzzy and processing parameters, applied in the direction of digital control, electrical program control, etc., can solve problems such as poor control performance, and achieve the effect of improving control performance and machine tool processing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

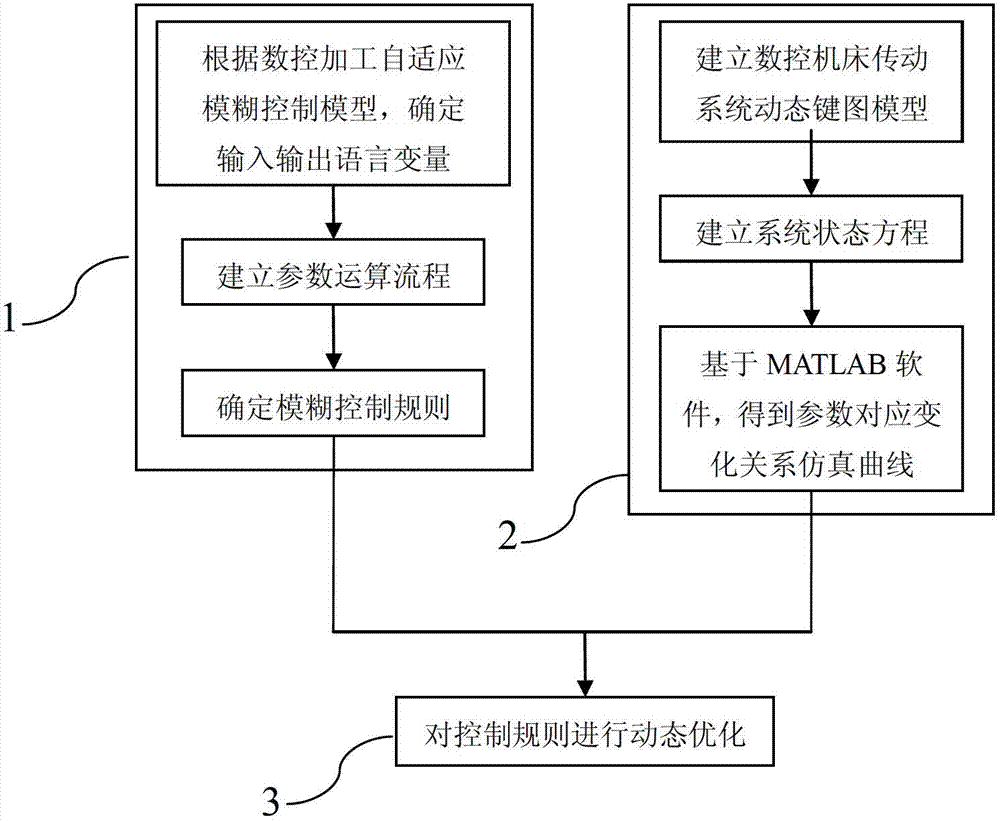

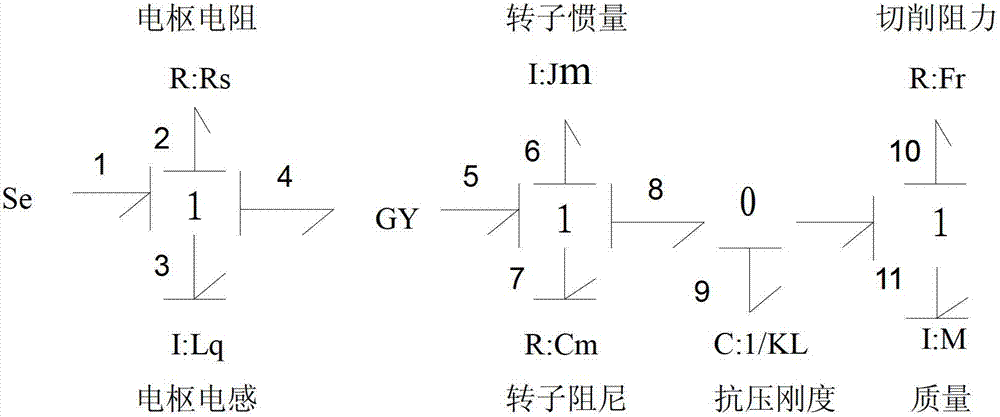

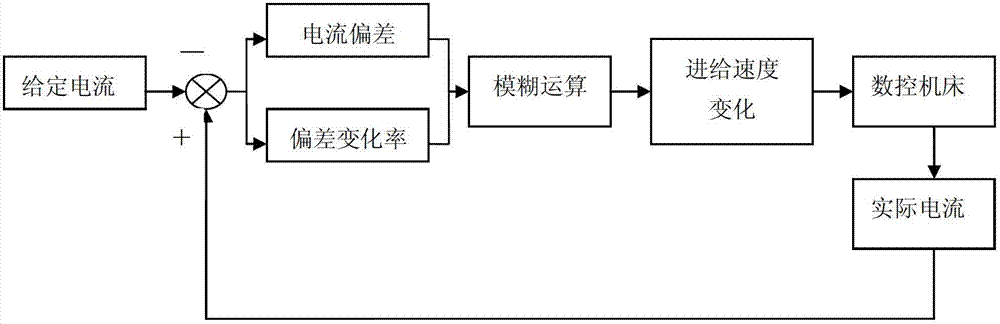

[0025] like figure 1 As shown, according to the NC machining adaptive control model, the input language variable current deviation E is obtained I , Deviation change rate EC I and output language variable feed speed change The relationship between the variable parameters is established to establish the variable parameter operation equation, so that the quantization files of the fuzzy set universe of the three linguistic variables all take the same value 6, and the membership functions are all expressed by triangular functions. According to the relationship between the input and output linguistic variables, the fuzzy Control rules, step 1; the transmission system of the machine tool includes the motor, mechanical transmission device and workbench, based on which the dynamic bond graph model of the CNC machine tool tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com