Supervision system and supervision method for die-casting production information

A technology of production information and supervision system, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of unfavorable production centralized monitoring and management, lack of contact, etc., to improve the level of automation management, ensure accuracy and timeliness Sexuality and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

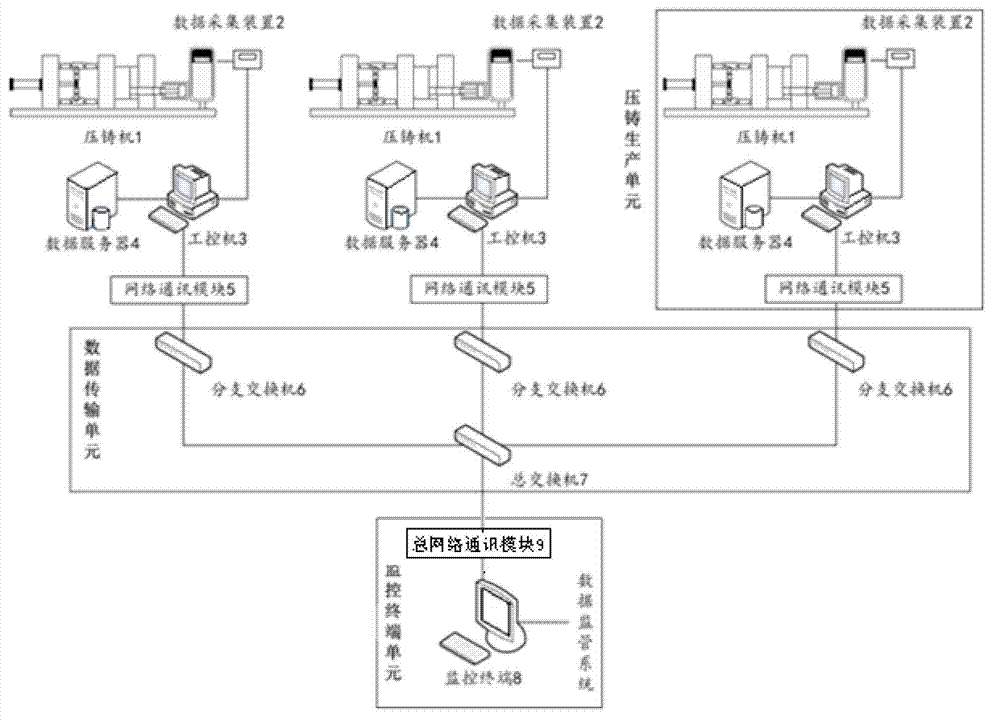

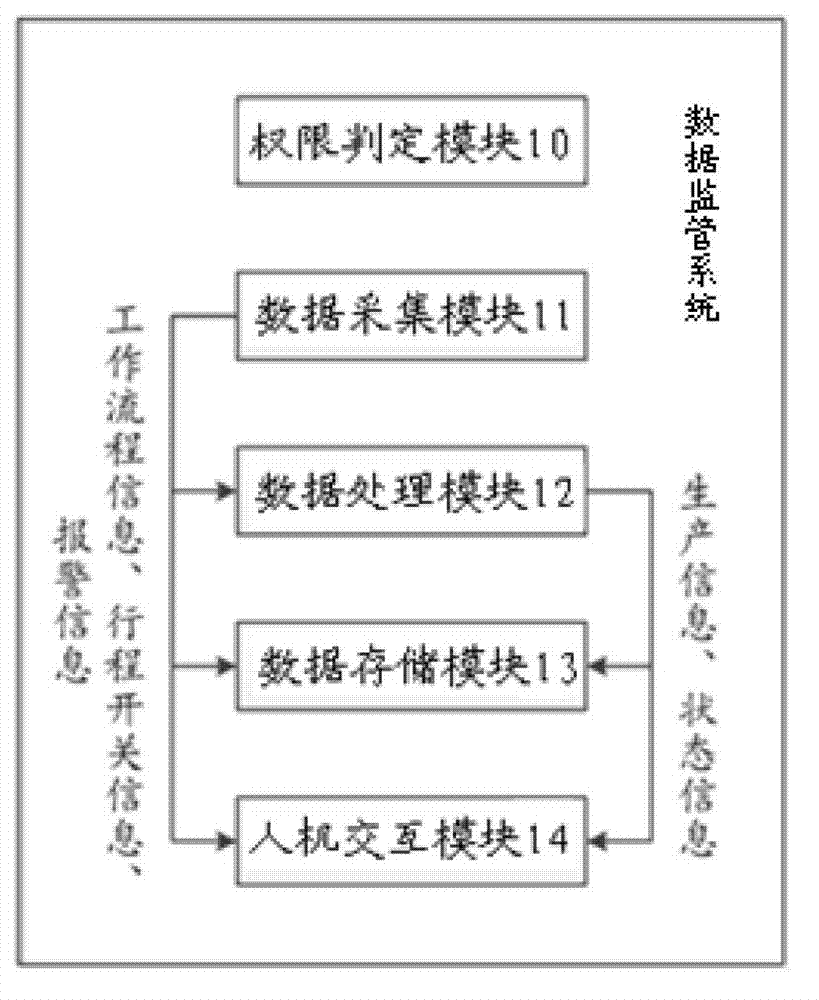

[0021] Such as figure 1 As shown, the present invention includes three parts: a die-casting production unit, a data transmission unit and a monitoring terminal unit.

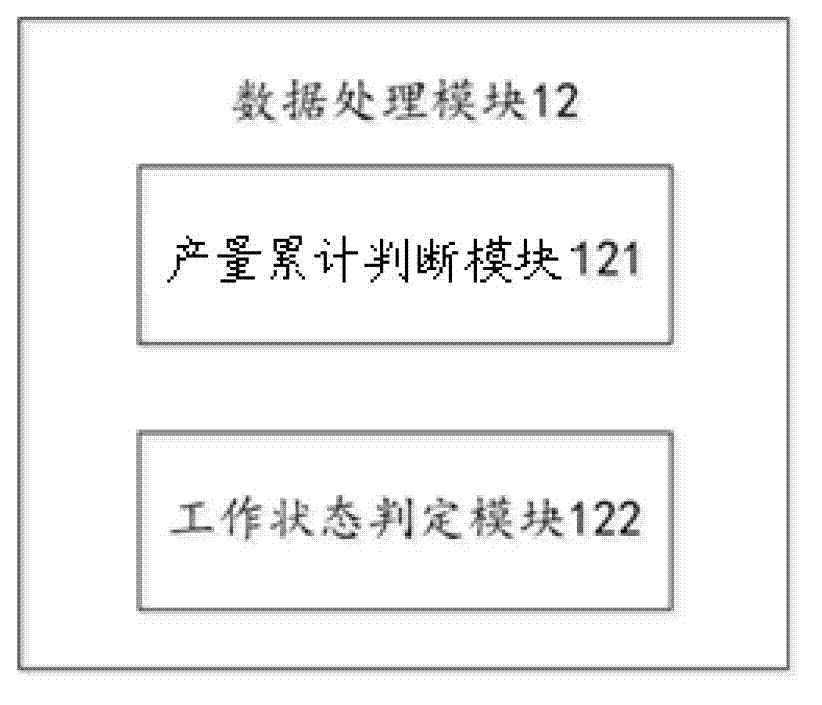

[0022] The die-casting production unit of the present invention includes several die-casting machines 1, and each die-casting machine 1 is provided with a data acquisition device 2 and an industrial computer 3, and each industrial computer 3 is provided with a data server 4 and a network communication module 5 . Each data acquisition device 2 is responsible for collecting the switching data information of the die-casting machine 1 connected to it, and stores it through the data server 4 in the industrial computer 3 connected to it, and transmits it externally through the network communication module 5 . Each network communication module 5 is provided with a network identification on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com