Manufacturing method of light-emitting diode packaging structure

一种发光二极管、封装结构的技术,应用在电气元件、电固体器件、电路等方向,能够解决影响发光二极管封装结构出光效果、荧光粉分布不均匀等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

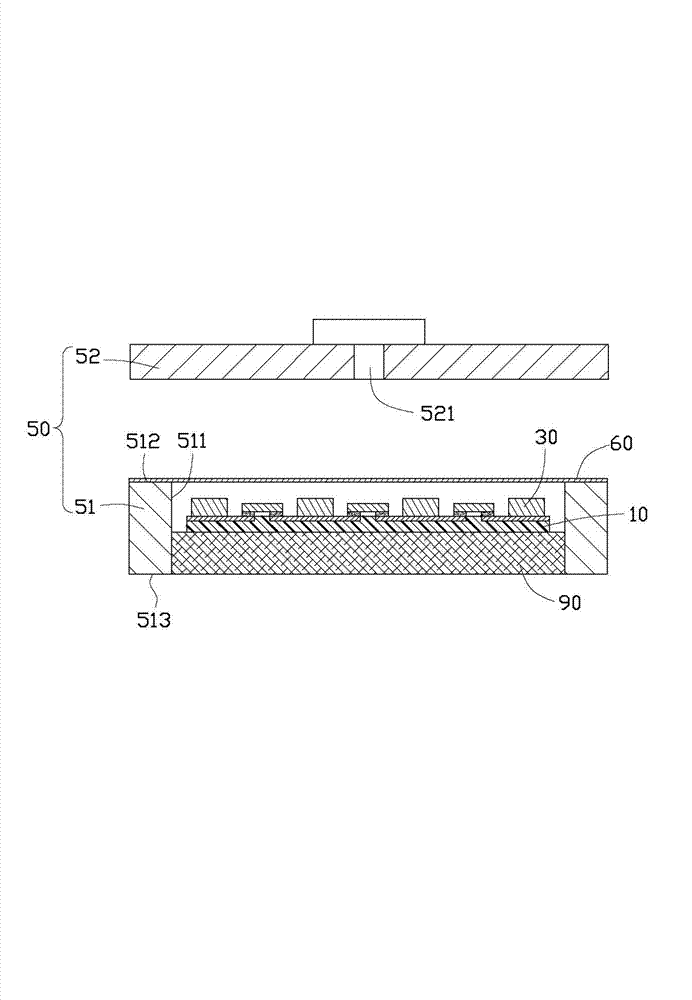

[0019] Such as Figure 9 As shown, the light emitting diode packaging structure 100 provided by the embodiment of the present invention includes a substrate 10, a circuit layer 20 formed on the substrate 10, a light emitting diode chip 30 carried on the substrate 10 and electrically connected to the circuit layer 20, a covering light emitting diode The fluorescent film 60 of the chip 30 and the packaging body 70 encapsulating the LED chip 30 .

[0020] In this embodiment, the light-emitting diode chip 30 is a horizontal structure, which is fixed and electrically connected to the circuit layer 20 of the substrate 10 by a flip-chip method. The LED chip 30 includes a light emitting surface 31 opposite to the substrate 10 , and two electrodes 32 are disposed on the other surface opposite to the light emitting surface 31 . The light emitting surface 31 faces away from the substrate 10 , and the two electrodes 32 face the substrate 10 and are connected to the circuit layer 20 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com