Compact type insulated gate bipolar transistor (IGBT) module driving unit

A drive unit, compact technology, applied in the direction of electrical components, output power conversion devices, etc., can solve the problems of circuit dispersion, low reliability and performance, inflexible configuration of protection and control functions, etc., to reduce workload, enhance versatility, The effect that is beneficial to the realization of the overheat protection and overcurrent protection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

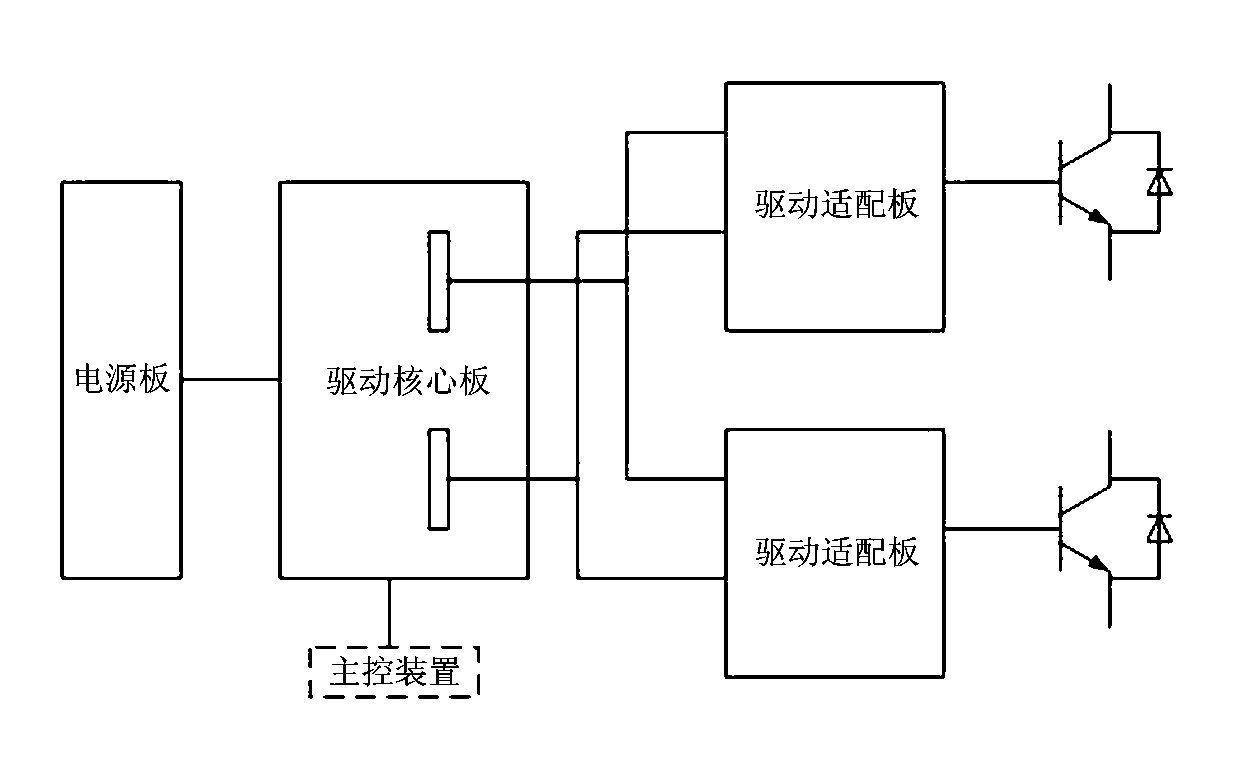

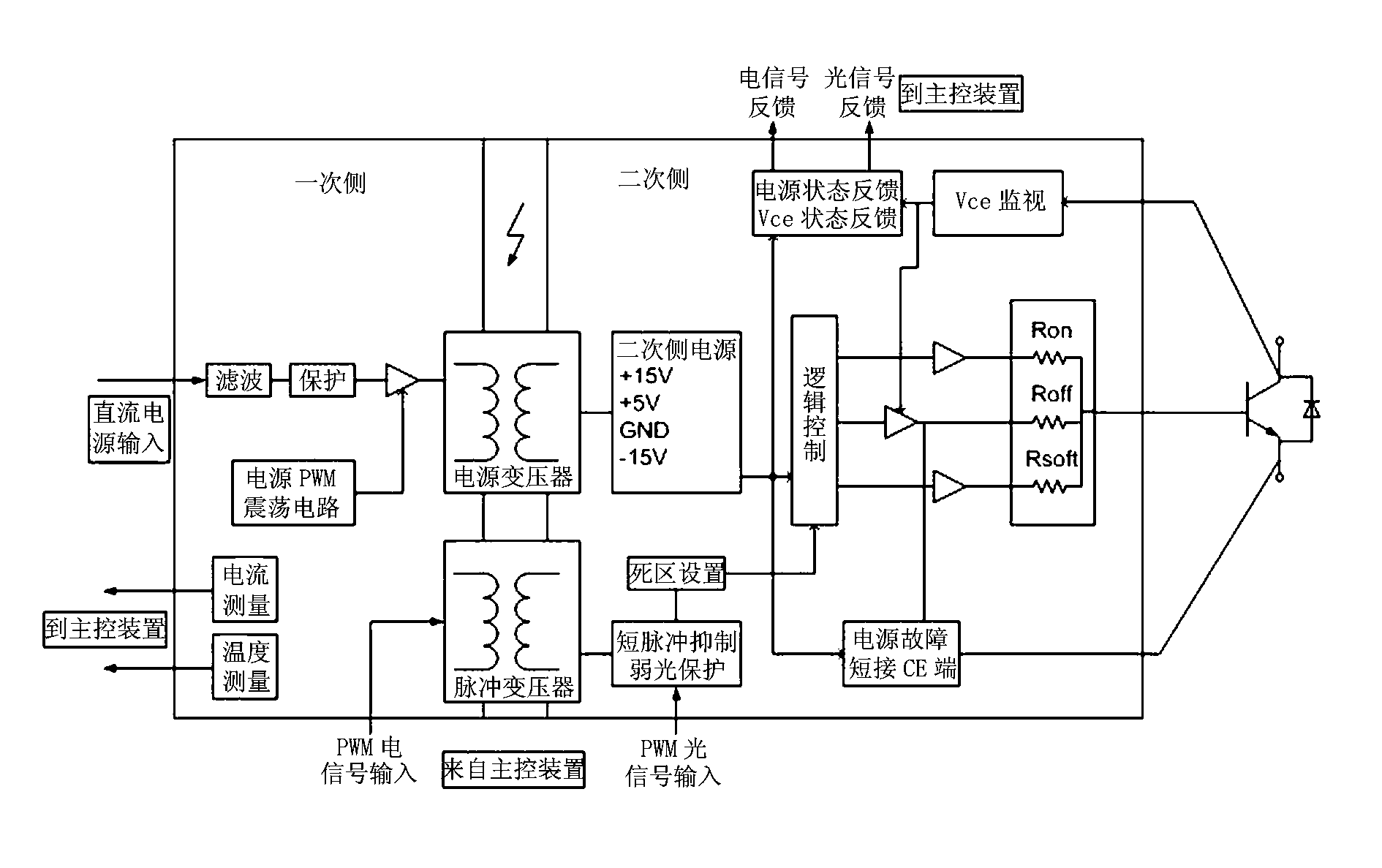

[0019] In order to further reveal the technical solutions of the present invention, the following describes the implementation of the present invention in detail in conjunction with the accompanying drawings: figure 1 As shown, a compact IGBT module drive unit is divided into three parts from the structural design: power supply board, drive core board and module adapter board. The power supply of the entire drive unit is taken from the high-voltage bus of the entire main circuit, and then converted into the voltage required by the drive core board and provided to the drive circuit; the protection and control circuits required for all types of IGBTs are set on the drive core board; for Different module adapter boards are designed for different types of modules, and the drive circuits are all set on the adapter board. The entire drive unit is composed of "power board + driver core board + module adapter board". Terminals are connected to achieve the goal of generalization.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com