System and method of online vision detection

A visual detection and detection device technology, applied in the direction of sorting, etc., can solve the problems that affect the product line qualification rate and material utilization rate, limited manual recognition ability, high missed detection rate of waste core columns, etc., to achieve real-time detection and high-definition and recognition, reducing the effect of repetition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below through specific embodiments.

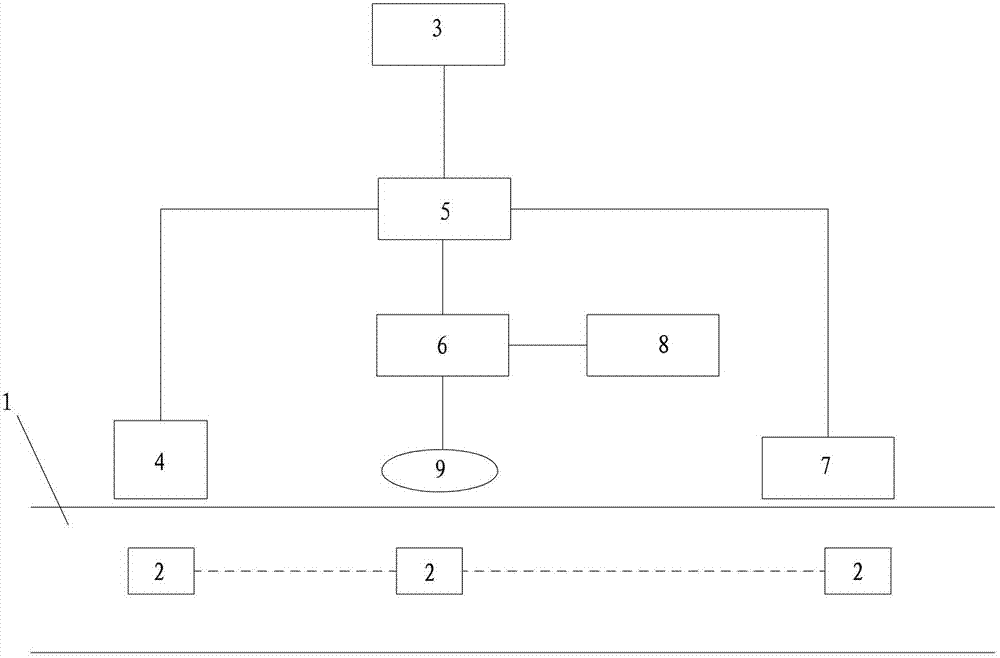

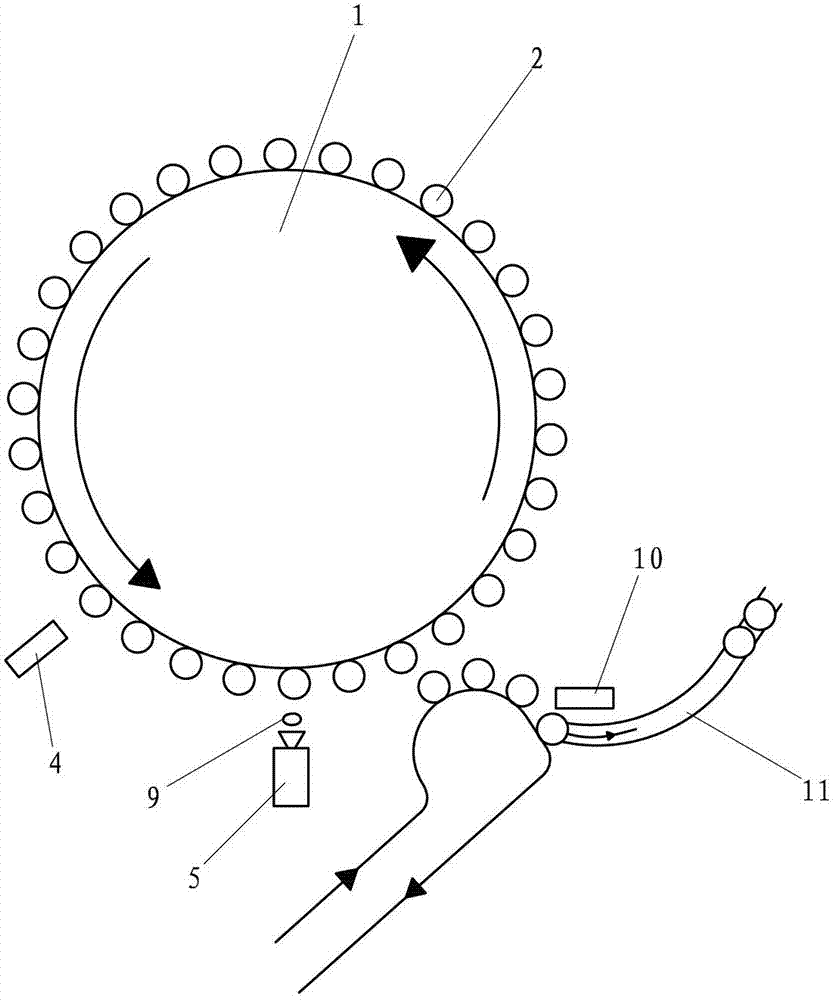

[0029] Reference figure 1 , figure 2 , An online visual inspection system, used to separate genuine and waste products on the mandrel 2 on the stretcher 1, including man-machine interface 3, position sensor 4, image acquisition and detection device 5, main control device 6 and waste Collecting device 7. The man-machine operation interface 3 is connected with the main control device 6 to provide an input interface for operating commands, including interfaces for changing various specifications. It is connected to the main control device 6 through the network. When the specifications need to be changed, the man-machine interface is used to operate , Switch quickly. The position sensor 4 is arranged on the stretcher 1 for detecting any position where the target core column 2 is located, and is set according to actual requirements and sends a flexible trigger signal to the main control dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com