Plate shape control method of hot rolled high-strength thin strip steel

A technology of shape control and thin strip steel, applied in the direction of contour control, etc., can solve the problems of high-strength thin strip steel plate shape fluctuation, large compound wave shape, etc., and achieve the effect of improving shape quality and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

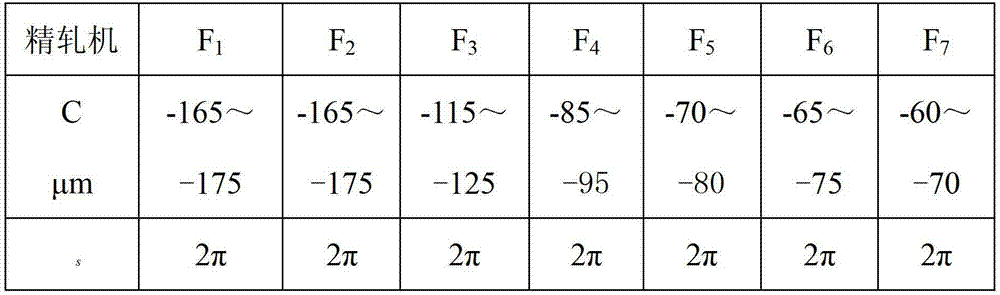

[0030] In the following, the present invention will be further described by taking the rolling material of AS600MC, the yield strength of 600MPa, and the thickness of the finished product of 2.0mm as an example of a 1580mm hot continuous rolling seven-stand finishing mill.

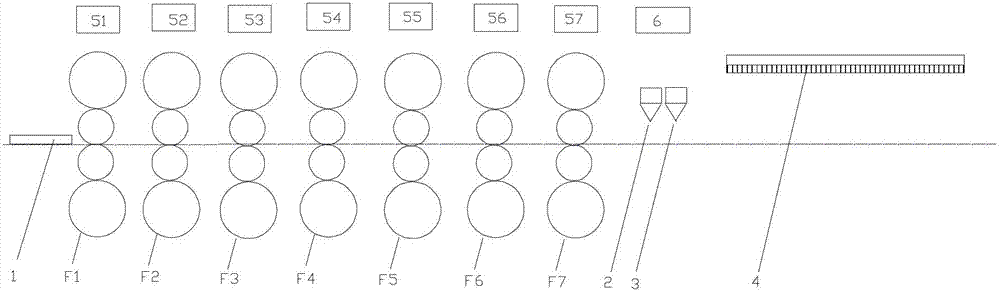

[0031] Depend on figure 1 It can be seen that strip steel 1 passes through F 1 , F 2 , F 3 , F 4 , F 5 , F 6 , F 7 and the shape meter 2 and the crown meter 3, and then pass through the laminar flow cooling device 4 with edge shielding. During the whole rolling process, the flatness automatic control system 6 adjusts F according to the strip shape control needs. 1 -F 7 The hydraulic bending rolls 51, 52, 53, 54, 55, 56, 57 of each stand rolling mill.

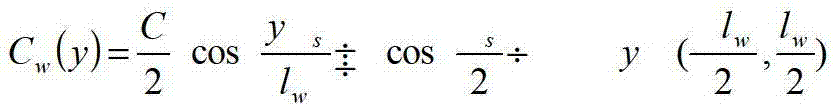

[0032] The basic strategy of flat shape control in the present invention is, in F 1 —F 4 After the four-stand finishing mill rolling, the proportional crown of the strip reaches the set target proportional crown, and at the same time, the 5 —F 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com