Measuring and welding device in metal mask plate assembling machine and moving mechanism of measuring and welding device

A metal mask and motion mechanism technology, which is applied in the field of mechanical devices, can solve problems such as affecting production efficiency and complicated OLED mask operation steps, saving machine space occupation, meeting various functional application requirements, and reducing cumbersomeness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

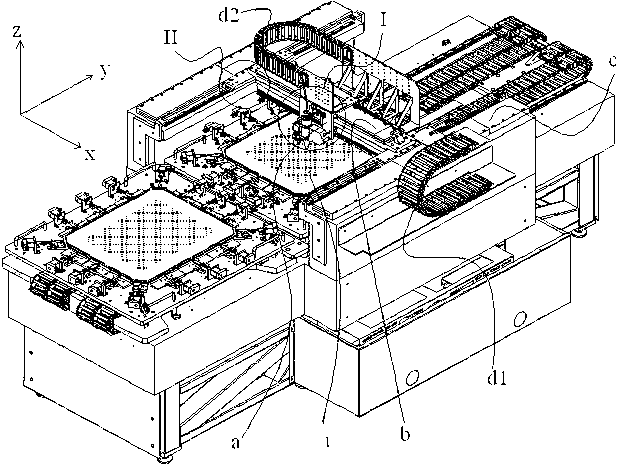

[0021] A metal mask board assembly machine measuring welding device, figure 1 Shown is a schematic diagram of the overall structure of the assembly machine involved, and this embodiment mainly describes the movement mechanism of its measuring welding device.

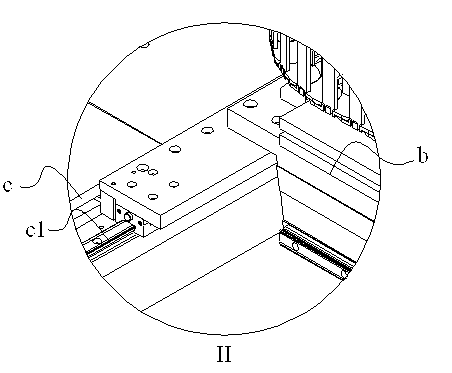

[0022] A movement mechanism of a metal mask assembly machine measuring welding device, which includes a slider a, a carriage b and a frame c, characterized in that the slider a can slide on the carriage b, and the carriage b can Move on rack c.

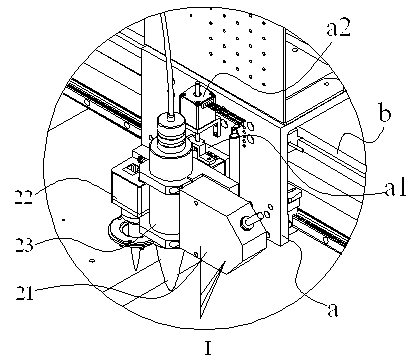

[0023] figure 2 Shown is a schematic diagram of the cooperation between the slider a and the carriage b, that is figure 1 The enlarged schematic diagram of the part I in the middle, the slider a can be moved along the upper side of the carriage b figure 1 Move in the x-axis direction shown; another example figure 2 As shown, there is a multi-element integration device that can move along the z-axis direction on the slider a. It is composed of a metal mask precision measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com