Manufacturing method of pre-baking aluminium cell shell

A technology of an aluminum electrolytic cell and a manufacturing method, which is applied in the directions of manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of damage to the electrolytic cell, stop production and maintenance, increase the maintenance cost and workload of the electrolytic cell, etc., so as to ensure the construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

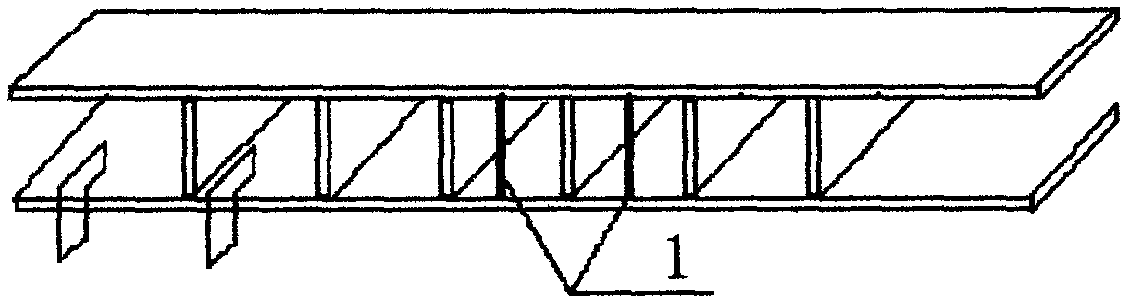

[0024] 1. Fabrication of the short side structure of the tank shell

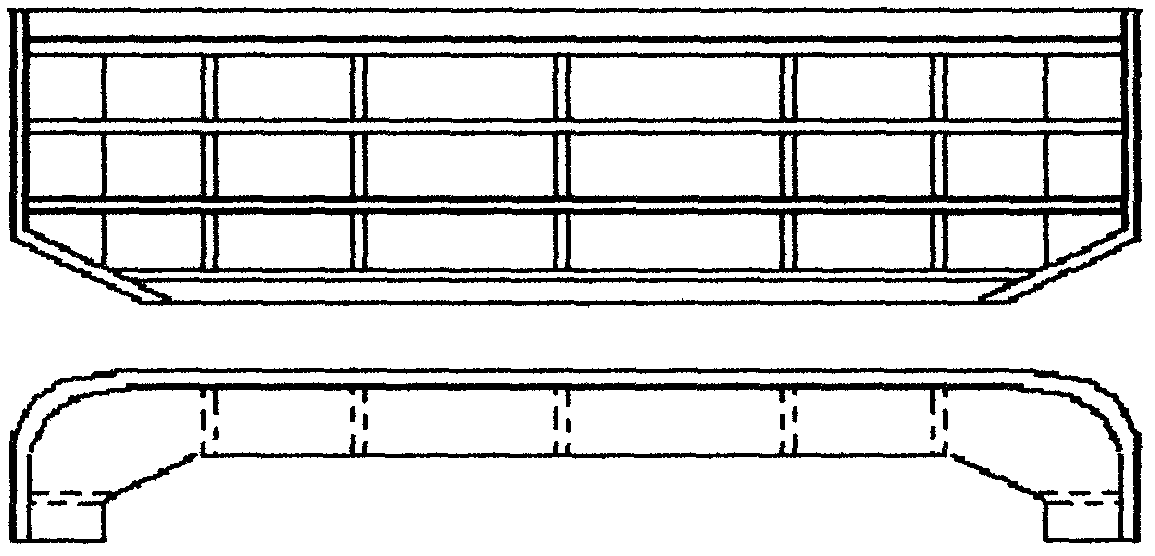

[0025] In order to control the welding deformation and ensure the production quality, the short side structure of the tank shell must be welded on the paired mould. The short side plate structure mould, such as figure 1 shown.

[0026] The short side plate structure uses a semi-automatic cutting machine for blanking or beveling.

[0027] After the short side wall plate and the shroud are cut and leveled, use the plate rolling machine to perform arc positioning according to the arc positioning, and check with the sample. The gap should not be greater than 1mm, and cut off the intersection line between the short side wall plate and the inclined side plate , set aside for use.

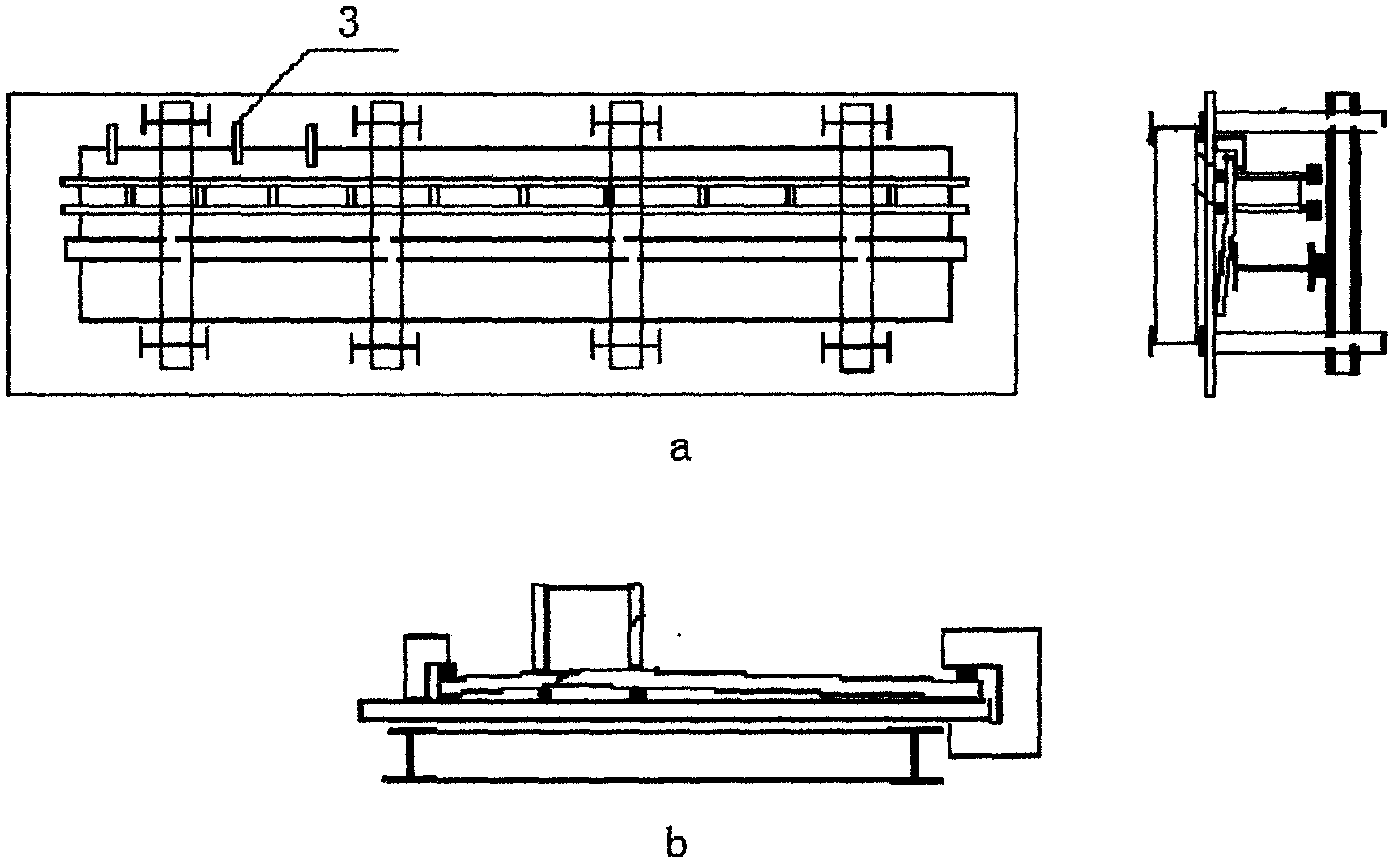

[0028] Buckle the rolled short side wall plate on the tire mold, and clamp the center with the clamp (3), draw the position lines of each group, and assemble in the order of along the plate→slope side plate→T-shaped plate→shroud Righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com