Grinding method for double-phase heat-resistant stainless steel continuous casting sheet billet

A technology of heat-resistant stainless steel and continuous casting, which is used in the field of slab repair and grinding in duplex and heat-resistant stainless steel continuous casting, can solve the problems of easy to produce wear marks, affect the surface quality of medium plate rolling, surface roughness, etc. The effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

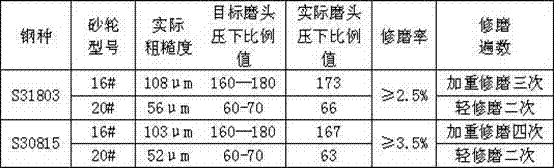

[0031] The continuous casting slab of dual-phase steel S31803 ground in this embodiment has a length of 2000 millimeters, a width of 1238 millimeters and a thickness of 160 millimeters.

[0032] 1. The first step is grinding with a 16# grinding wheel

[0033] 1. Equipment used: billet surface grinding machine.

[0034] 2. Grinding wheel angle: 45°;

[0035] 3. Speed of trolley: 50m / min;

[0036] 4. Feed rate: 30mm;

[0037] 5. Proportional value of grinding head depression: aggravated grinding 173

[0038] 6. Grinding rate of two surfaces: ≥2.5%, {repairing rate = (weight of billet before grinding - weight after grinding) ÷ weight before grinding}, each side is regrinded 3 times

[0039] 7. Surface roughness R on both sides of the slab after grinding Z 108 μm.

[0040] 2. In the second step, use a grinding wheel with a particle size of 20# to grind

[0041] 1. Equipment used: billet surface grinding machine.

[0042] 2. Grinding wheel angle: 45°;

[0043] 3. Speed ...

Embodiment 2

[0049] The continuous casting slab of the heat-resistant steel grade S30815 that this embodiment grinds, the length of casting slab is 2000 millimeters, wide 1238 millimeters, thick 160 millimeters.

[0050] 1. The first step is grinding with a 16# grinding wheel

[0051] 1. Equipment used: billet surface grinding machine.

[0052] 2. Grinding wheel angle: 45°;

[0053] 3. Speed of trolley: 50m / min;

[0054] 4. Feed rate: 30mm;

[0055] 5. Proportional value of grinding head depression: heavy grinding 167

[0056] 6. Grinding rate of both surfaces: ≥3.5%, {repairing rate=(weight of billet before grinding-weight after grinding)÷weight before grinding}, each side is re-grinded 4 times

[0057] 7. Surface roughness R on both sides of the slab after grinding Z 103 μm.

[0058] 2. In the second step, use a grinding wheel with a particle size of 20# to grind

[0059] 1. Equipment used: billet surface grinding machine.

[0060] 2. Grinding wheel angle: 45°;

[0061] 3. Spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com