A hydraulic group control energy-saving system

An energy-saving system and hydraulic technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve the problem of energy saving space approaching the limit, etc., and achieve the convenience of energy saving, weight reduction and precious space saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] In the implementation example, the present invention provides a principle diagram and a composition method of a group control hydraulic structure constituting a class of single equipment. The invention illustrates the relationship among various structures, the necessary conditions for constituting the energy-saving system and the method for realizing it.

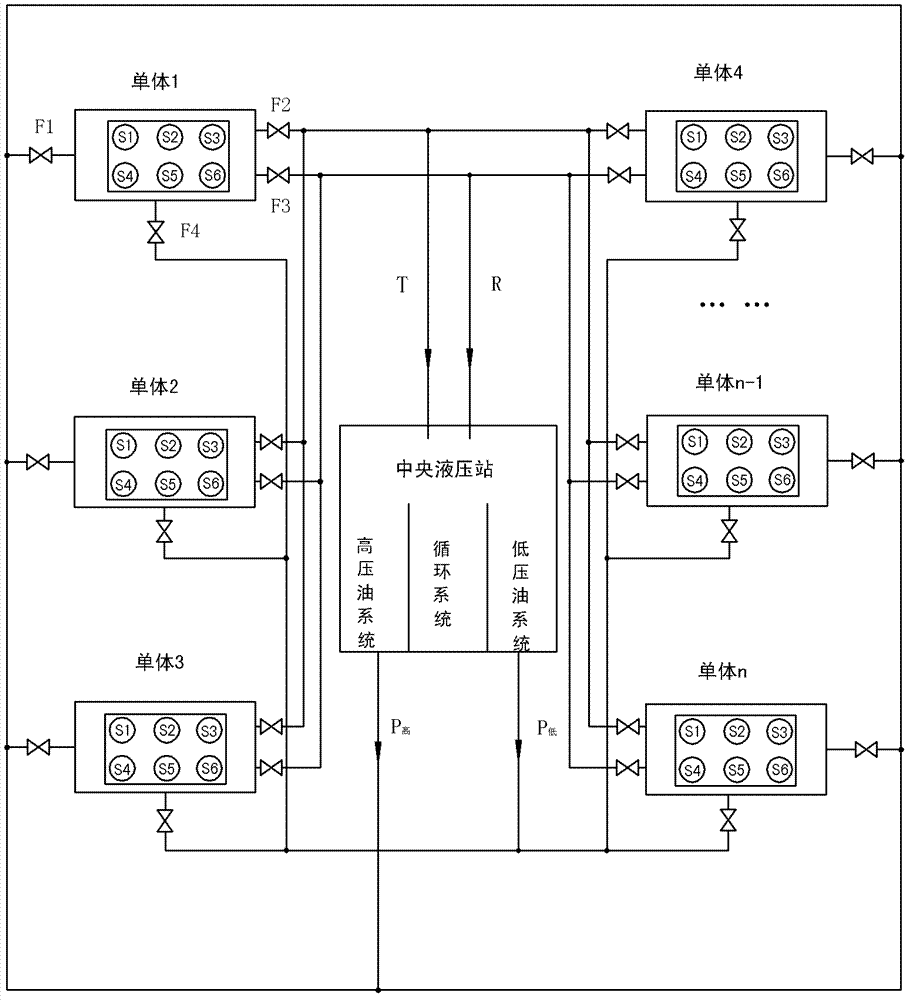

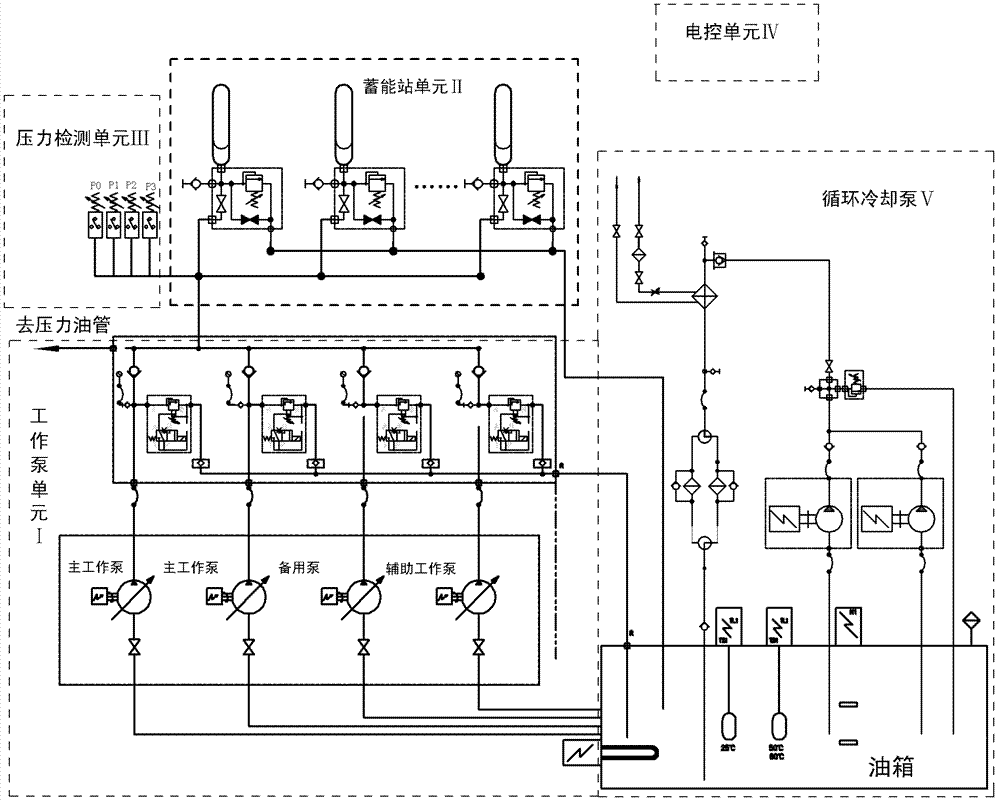

[0038] Such as figure 1 As shown, there are n individual devices (such as injection molding machines) in a region, and these n individual devices share a central hydraulic station. The internal structure of the hydraulic station is shown in figure 2 shown. For details, refer to the following description.

[0039]In actual work, the single equipment we encounter may be more complicated. Some single equipment only needs high-pressure oil supply, some single equipment only needs low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com