Air chamber for baking oven and baking oven

An air chamber and chamber technology, which is applied in the field of air chambers and ovens, can solve the problems of difficulty in achieving wind speed, uneven air outlet air speed, and indeterminate air speed, and achieve the effects of convenient design and adjustment, cost saving and efficiency increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

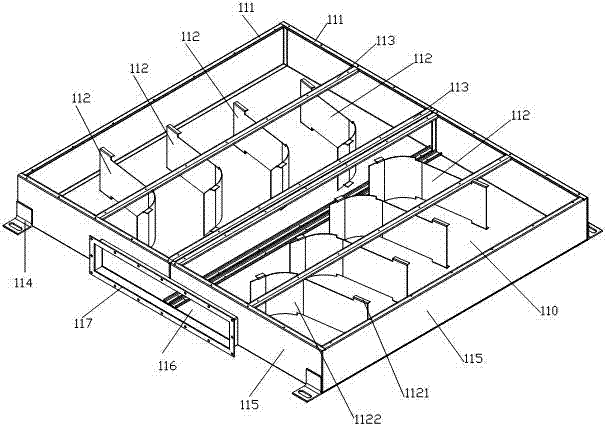

[0027] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings of the embodiments, so as to make the technical solutions of the present invention easier to understand and grasp. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

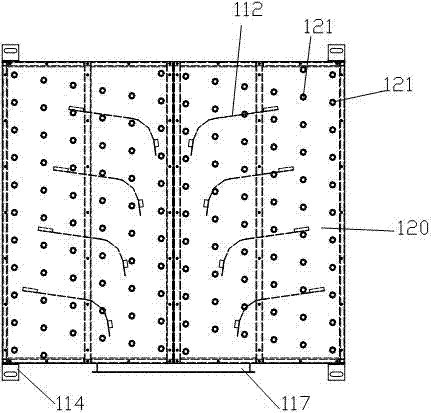

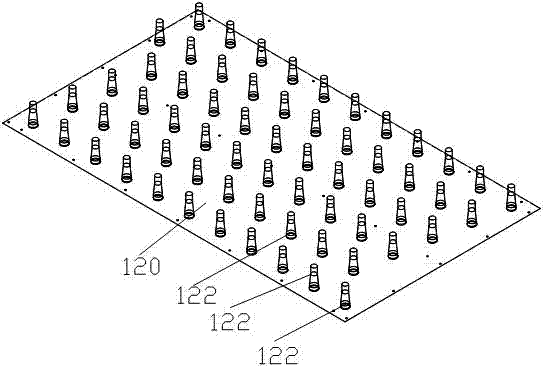

[0028] The present invention provides an oven, which can be used as a part of an automatic forming paper mold drying device for drying a certain shape of paper mold wet blank products manufactured by a paper mold forming machine, and can also be used for drying other needs. Dried product. The preferred embodiment is Figure 4 , Figure 5 As shown, the oven includes several air chambers 100. The air chambers 100 are divided into an upper air chamber 010 and a lower air chamber 020. The upper air chambers 010 and the lower air chambers 020 are equal in number and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com