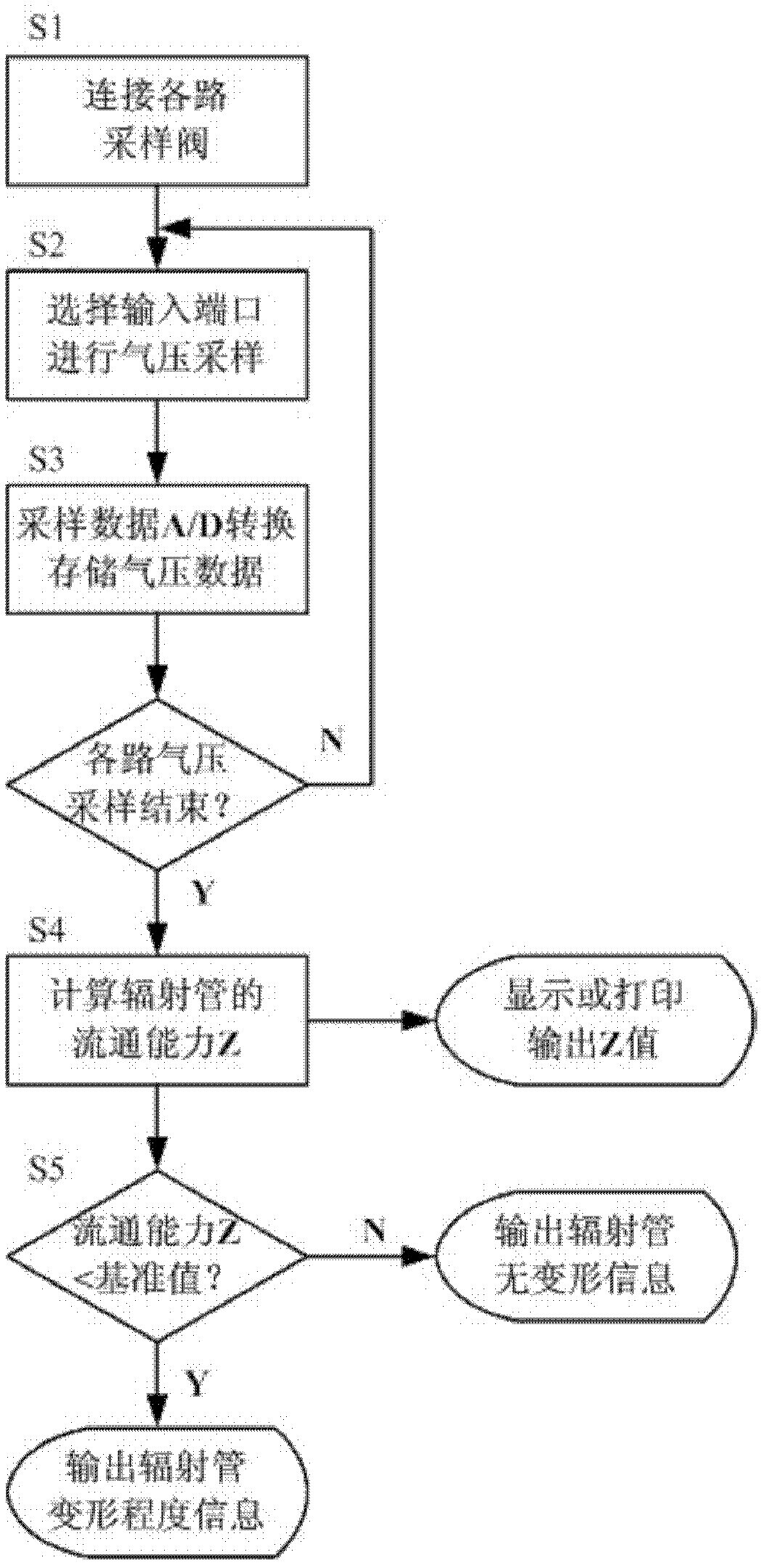

Method and device for detecting radiant tube deformation outside furnace

A detection device and radiation tube technology, which is applied to measuring devices, instruments, etc., can solve problems such as radiation tube deformation, and achieve the effect of saving time for regular repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

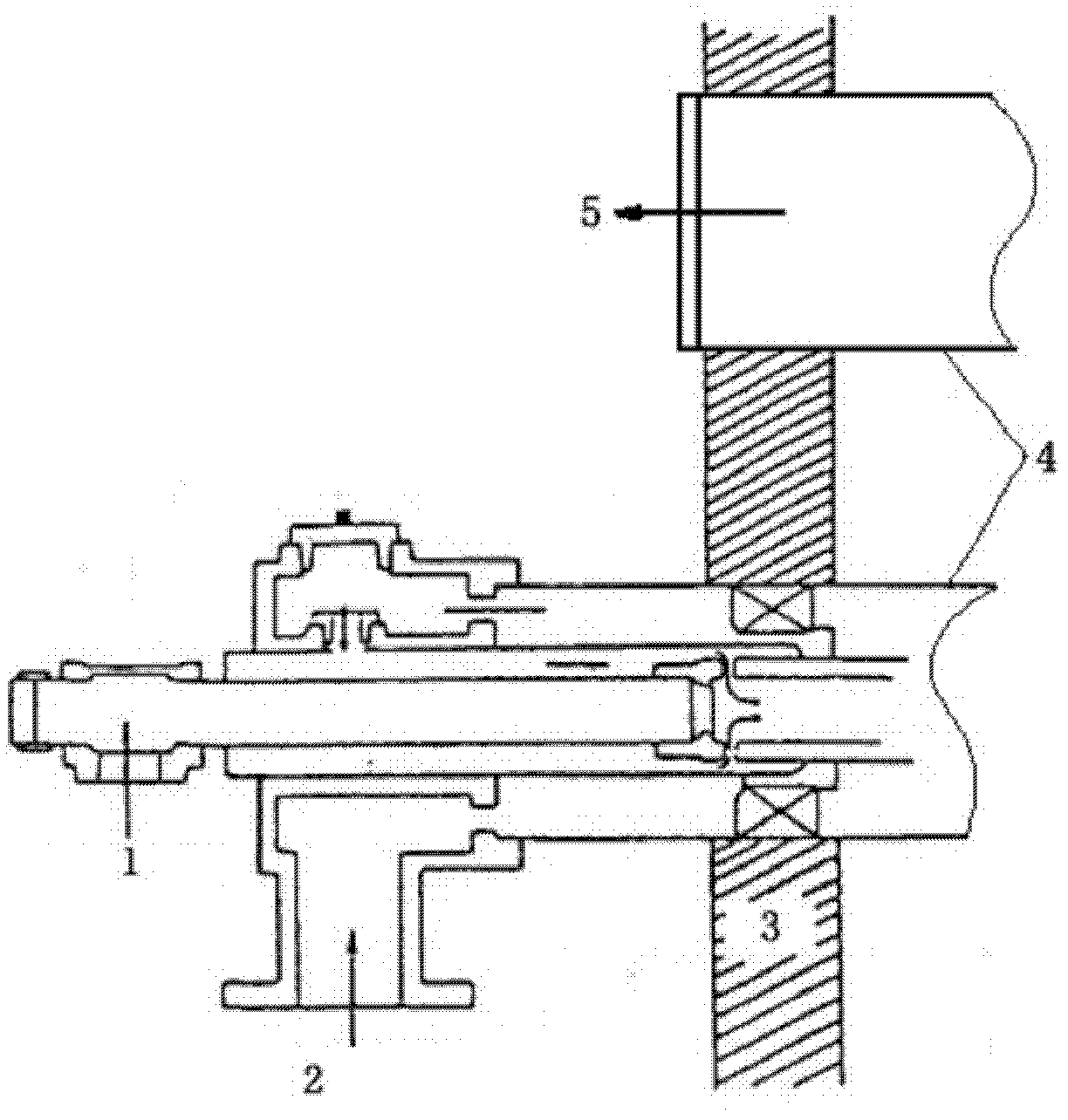

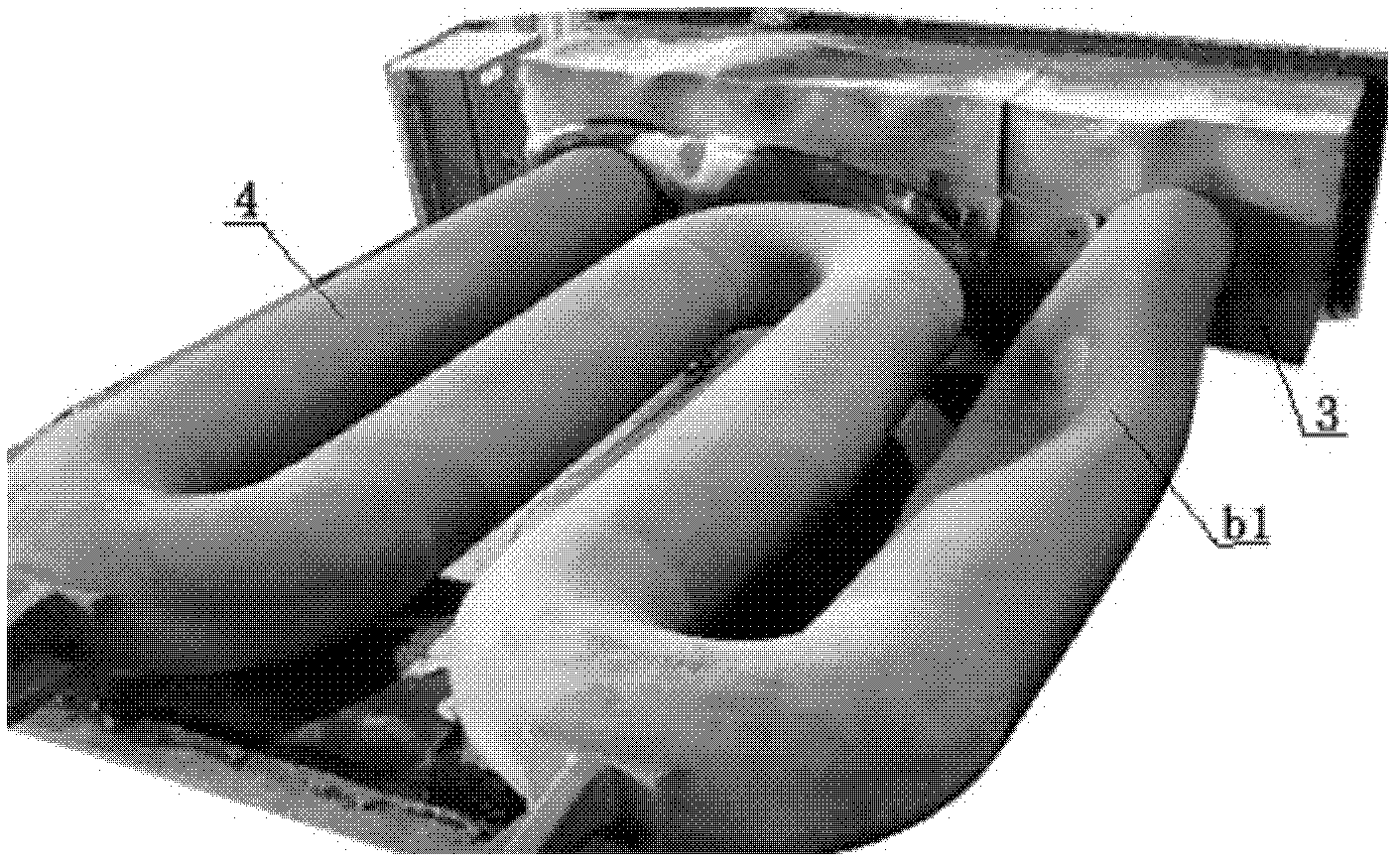

[0035] The continuous annealing furnace heating section of the continuous annealing unit usually adopts W-shaped radiant tubes to burn coke oven gas for heating. The radiant tube heating device includes a main burner, an igniter and a burner combustion monitor device. The air passage structure of the commonly used radiant tube burner is as follows: figure 1 shown in figure 1 In the drawing, the radiant tube 4 is omitted, and only the part close to the furnace wall 3 is drawn for the inner part of the furnace. The gas enters through the inlet 1 of the gas channel, and the combustion-supporting air blows into the radiant tube 4 through the main blower, and enters the heat exchange device through the inlet 2. After being preheated by the high-temperature combustion waste gas inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com