Acoustic detection method and device for egg cracks based on continuous vibration sound production

An egg and crack technology is applied in the field of egg detection, which can solve the problems of egg damage, restricting the running speed of a knocking mechanism, etc., and achieves the effects of low cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

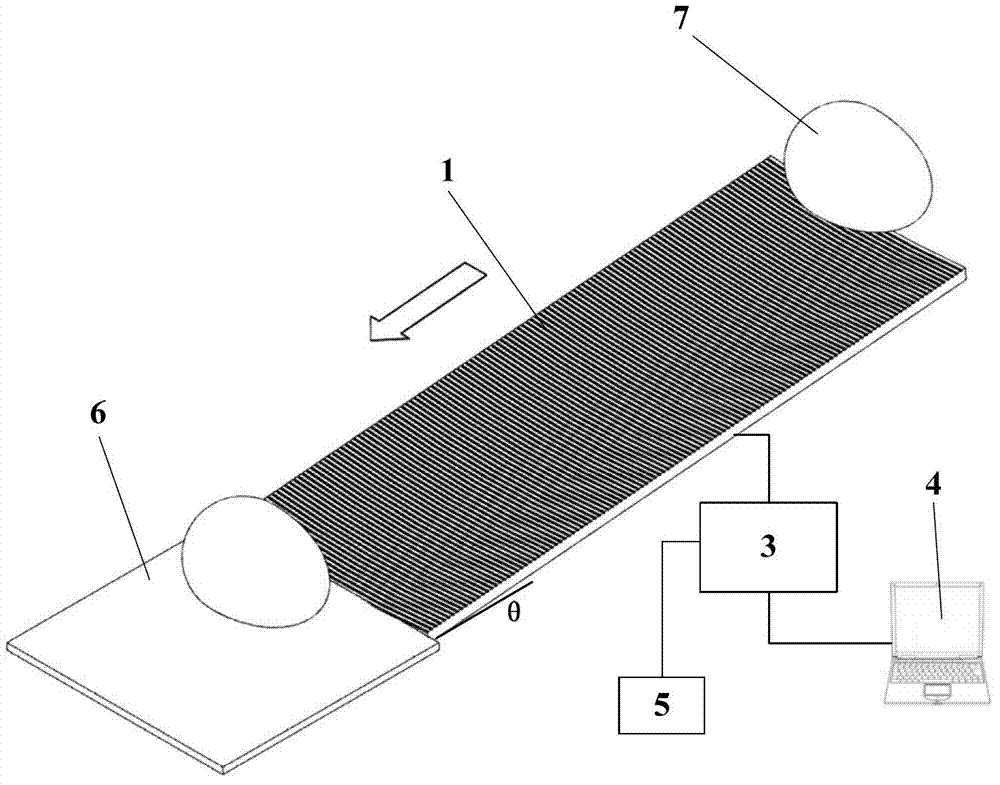

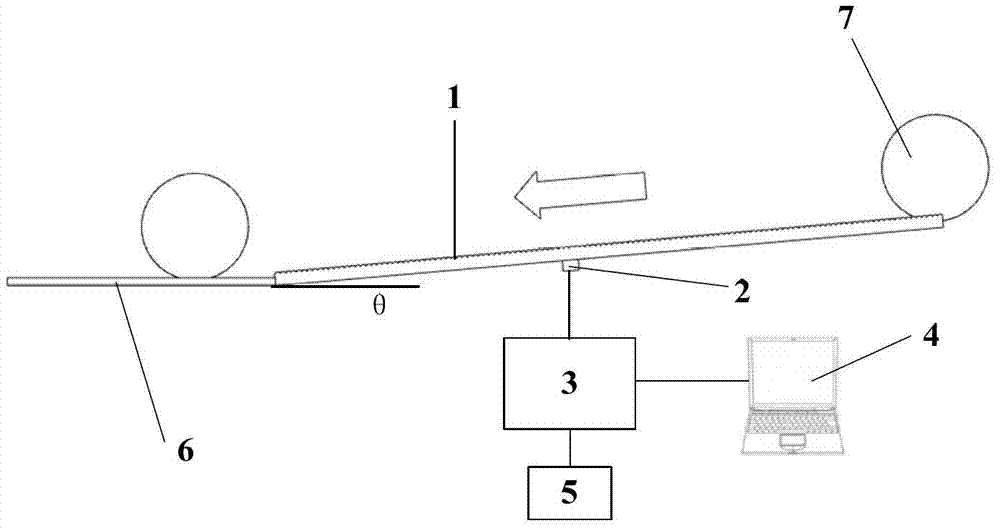

[0070] The present invention includes a corrugated board 1 with corrugations on the upper surface, where the material of the corrugated board 1 is steel, the thickness is 5 mm, the width is 100 mm, and the length is 250 mm. The corrugation interval is 1mm, the corrugation width is 1mm, and the direction of corrugation is perpendicular to the rolling direction of poultry eggs. The inner surface of the corrugated board has an arc-shaped depression with a radius of 850 mm. The purpose of this arc-shaped depression is to guide the detected poultry eggs so that they roll down along the center line of the corrugated board 1 . Microphone 2, amplifier 3, computer 4, power supply 5, buffer pad 6; one end of the corrugated board 1 is elevated by a certain angle θ, and the range of the angle θ can vary from 0° to 60°, and placed on the lower end of the corrugated board 1 A soft buffer pad 6, the microphone 2 is placed close to the center of the back of the corrugated board 1, the microph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com