Embedded perception device and method for multi-source manufacturing information

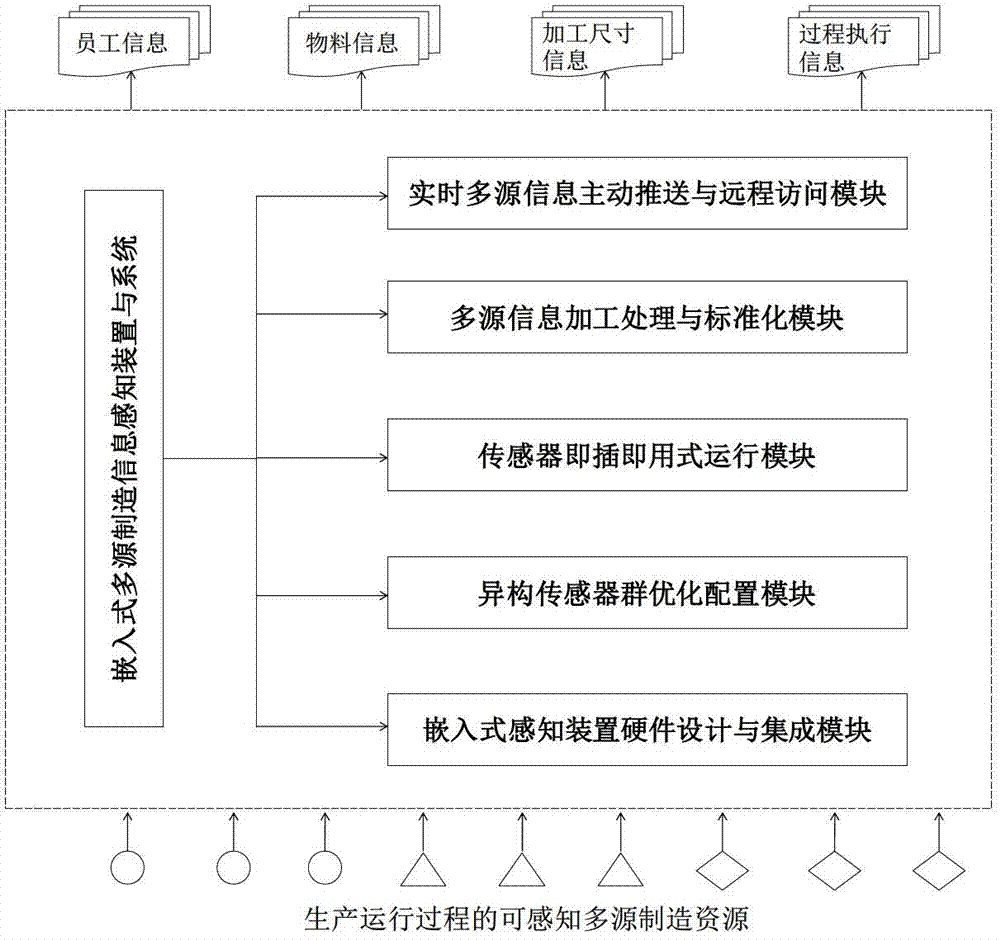

A technology of information perception and multi-source information, which is applied in the field of embedded multi-source manufacturing information perception devices, can solve the problems of disconnection of bottom-level information in the upper-level management system and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

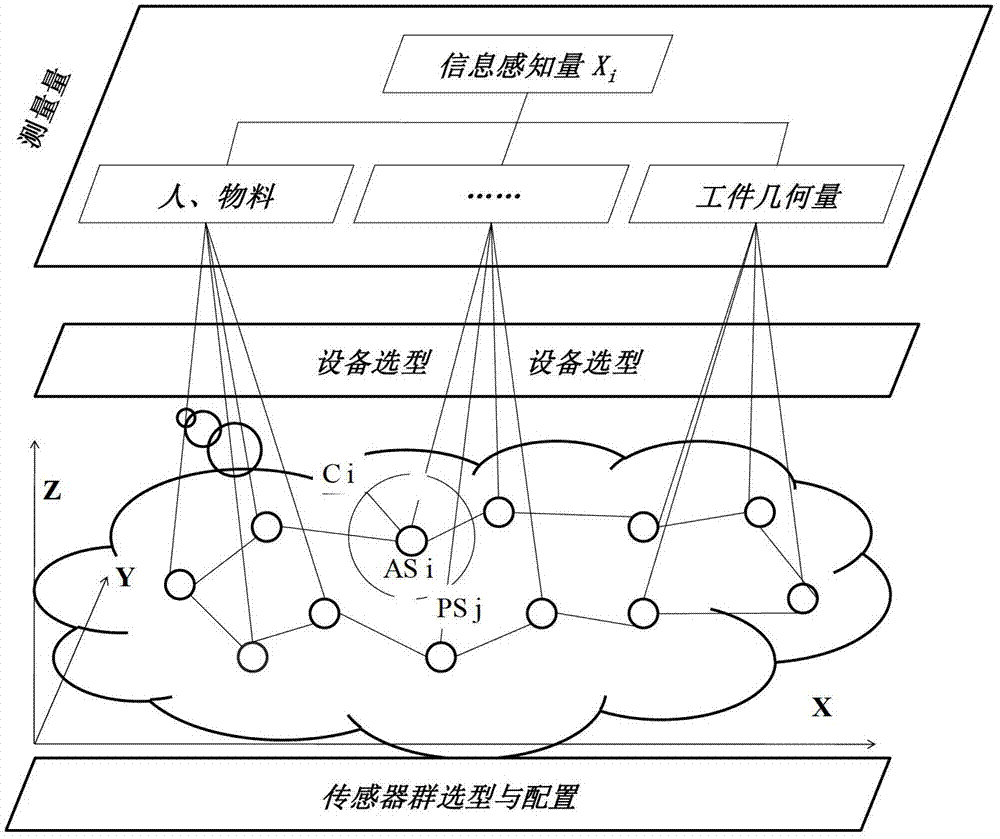

Method used

Image

Examples

Embodiment Construction

[0037] Describe the present invention below in conjunction with specific embodiment:

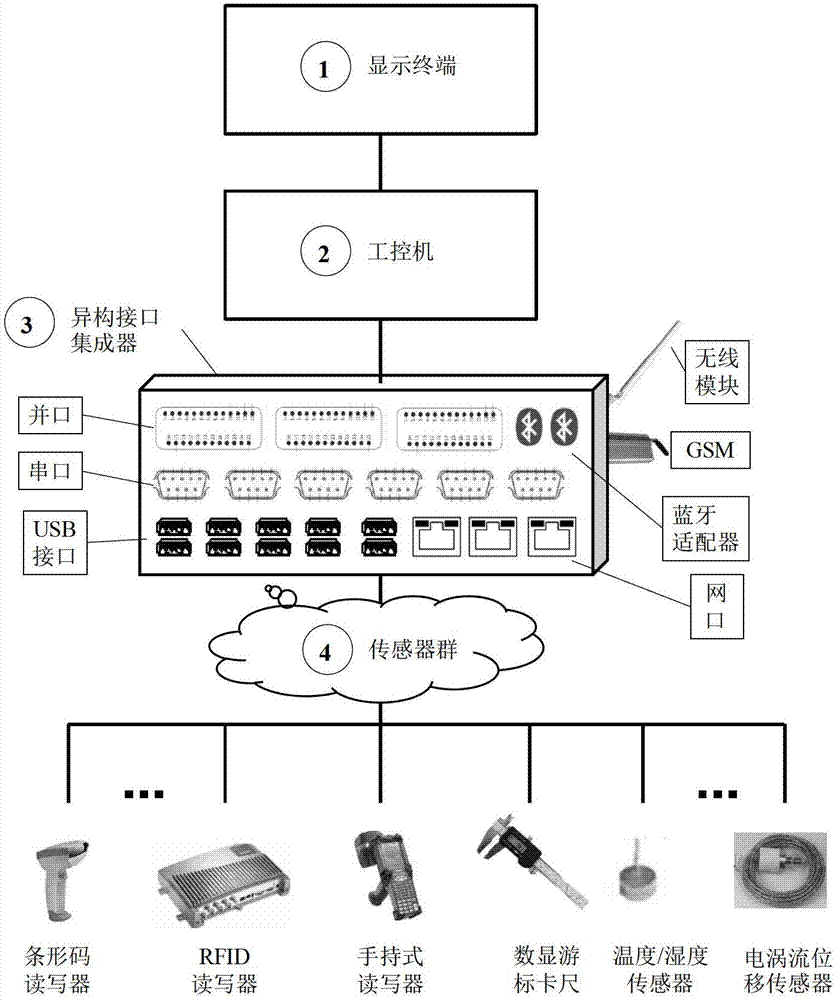

[0038] Refer to attached figure 2, the embedded multi-source manufacturing information sensing device in this embodiment is the hardware basis for the integrated operation and management of heterogeneous sensors that perceive multi-source manufacturing information, and it includes a heterogeneous interface integrator, an industrial computer, a heterogeneous sensor group, and a display terminal. parts. The heterogeneous sensor group is a variety of heterogeneous sensors built from the hardware level for the collection of multi-source manufacturing information, including radio frequency identification equipment, barcode scanning equipment, displacement sensors, digital display vernier calipers, roughness strategists, temperature sensors, humidity Various sensor groups of sensors; the heterogeneous interface integrator is used to integrate various heterogeneous interface terminals to realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com