Novel powder fluidized bed drying machine

A powder flow and dryer technology, used in dryers, dry solid materials, dry goods handling, etc., can solve problems such as poor adaptability of drying media, materials prone to bias flow, and asynchronous motors, so as to improve airflow distribution, reduce The effect of energy consumption and air distribution evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

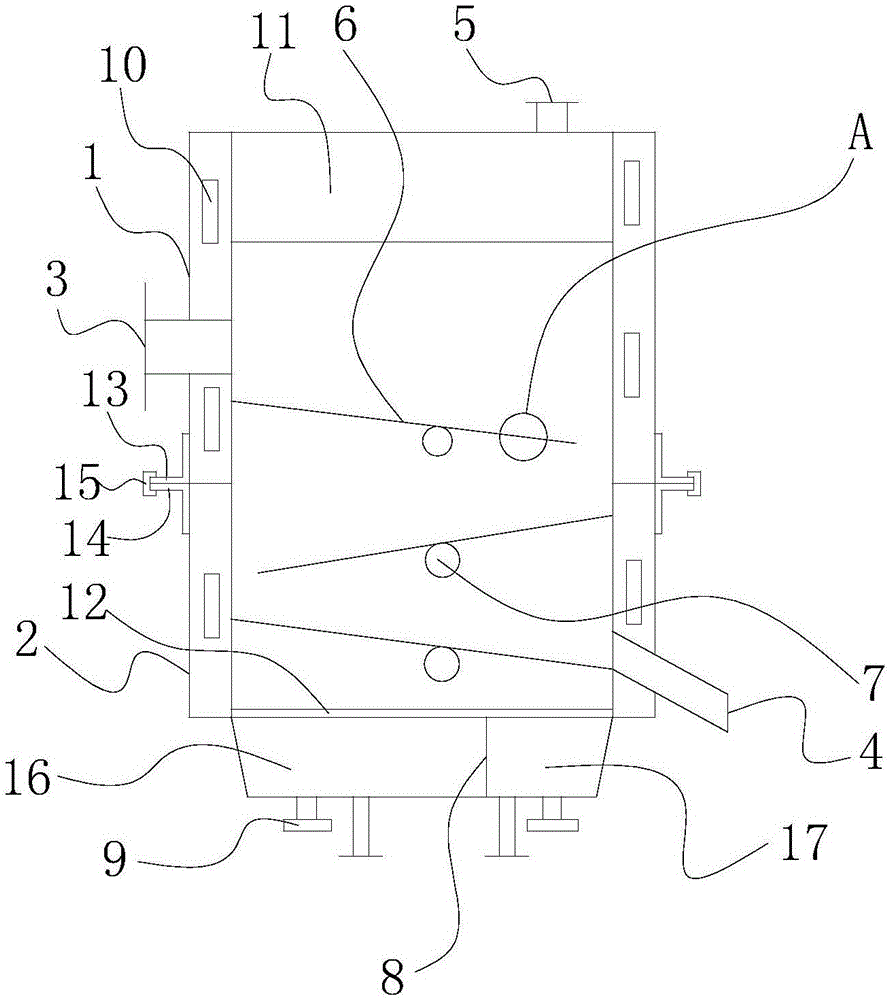

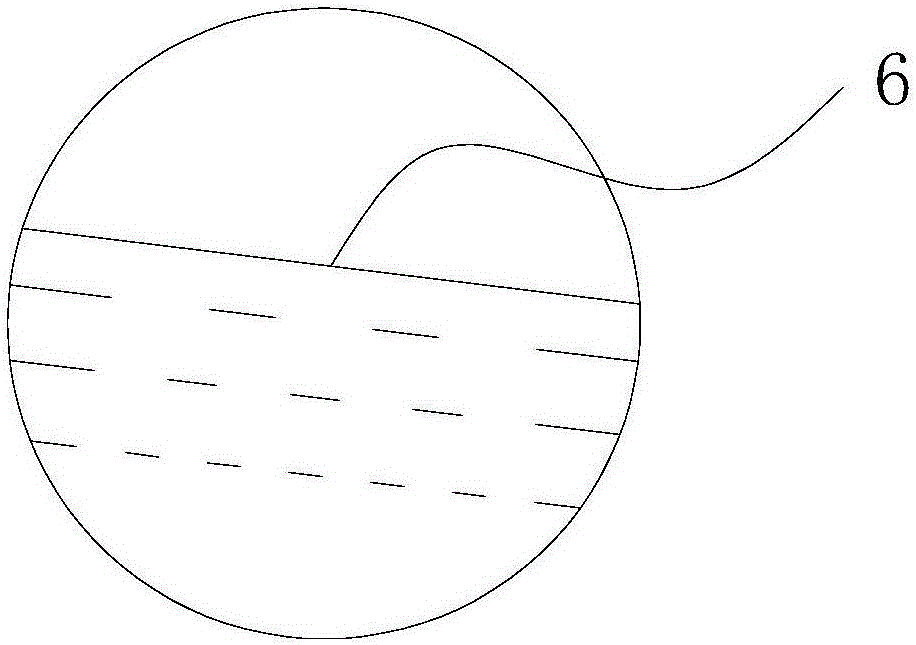

[0016] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0017] Such as figure 1 and figure 2 The new powder fluidized bed dryer shown includes a shell, which is installed on the ground through a vibration isolation spring 9. The shell is composed of an upper shell 1 and a lower shell 2 with a split structure. The upper shell 1 and the lower shell The shells 2 are connected by a quick-release structure; the side wall of the upper shell 1 is provided with a feed port 3, the upper surface of the upper shell 1 is provided with an exhaust port 5, and the side wall of the lower shell 2 is provided with a discharge port 4; The cavity formed by the upper shell 1 and the lower shell 2 is distributed with a filter cavity, a fluidization cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com