A method for automatic generation of 3D process model of shaft machining parts

A process model and automatic generation technology, applied in 3D modeling, instruments, data processing applications, etc., can solve the problems of complex segmentation and combination algorithms, cumbersome operation steps, low accuracy, etc., to reduce algorithm complexity and simplify operations. process, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

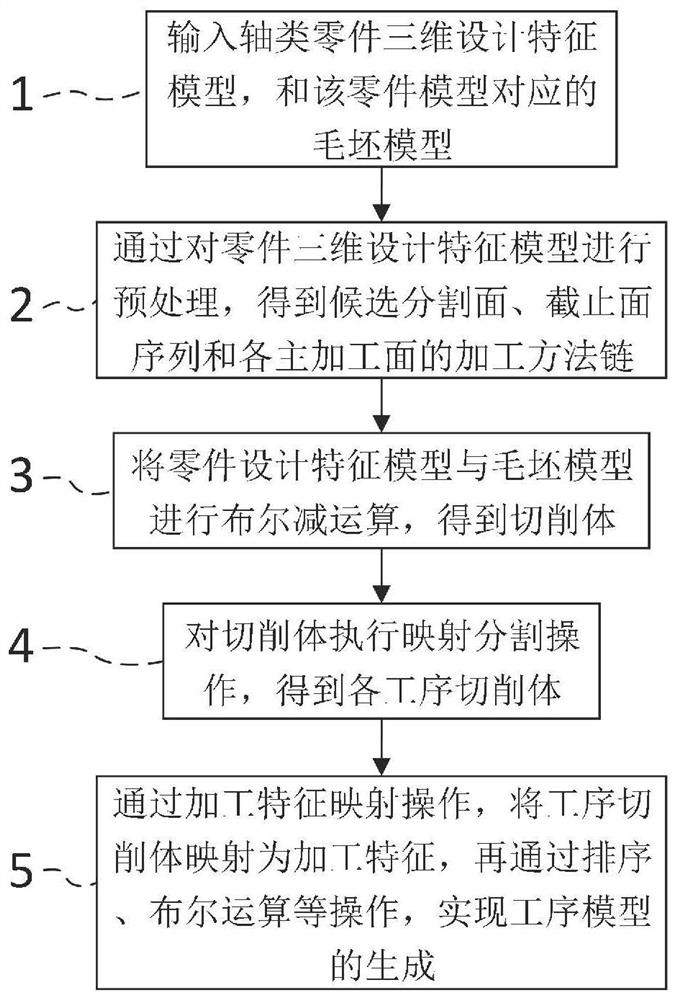

[0040] Such as figure 1 As shown, a method for automatically generating a three-dimensional process model of a shaft machined part is characterized by:

[0041] 1) Input the 3D design feature model of the shaft part and the blank model corresponding to the part model;

[0042]2) By preprocessing the three-dimensional design feature model of the part, the sequence of candidate segmentation surfaces and the processing method chain of each main processing surface are obtained;

[0043] 3) Carry out Boolean subtraction operation between the part design feature model and the blank model to obtain the cutting body;

[0044] 4) Execute the mapping and segmentation operation on the cutting body to obtain the cutting body of each process;

[0045] 5) Through the processing feature mapping operation, the process cutting body is mapped to the processing feature, and then the process model is generated through operations such as sorting and Boolean operations.

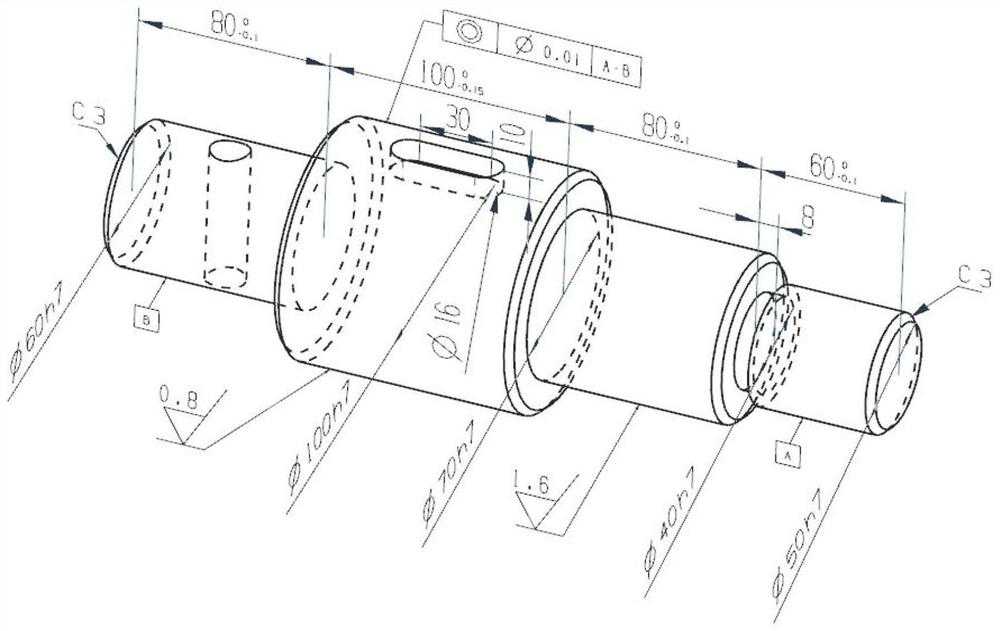

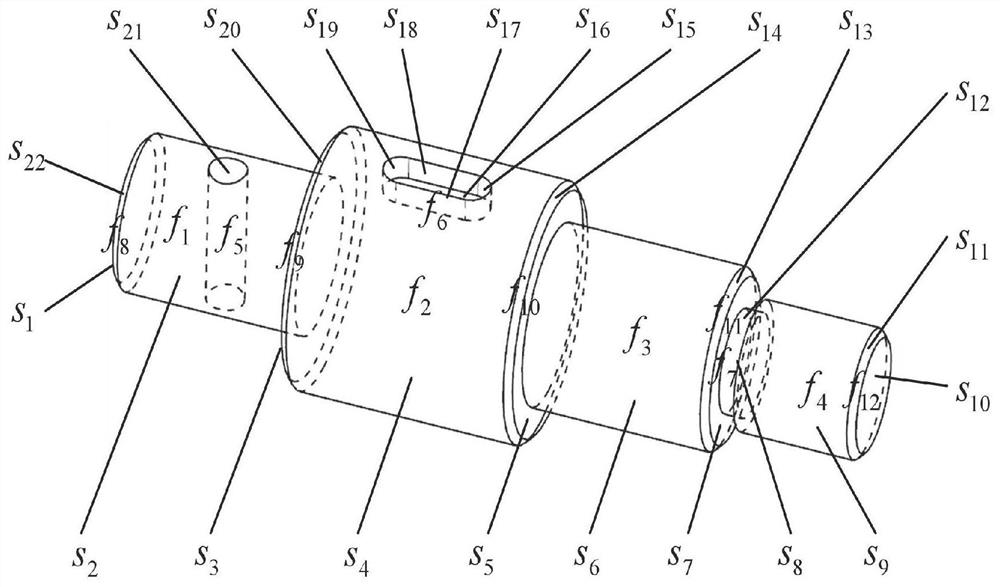

[0046] figure 2 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com