Ceramic component and method for producing a ceramic component

A technology of devices and ceramics, which is applied in the field of manufacturing such devices, can solve the problems of accuracy limitation, high total capacitance value, capacitance cannot be arbitrarily reduced, etc., and achieve the effect of tolerance balance and small capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

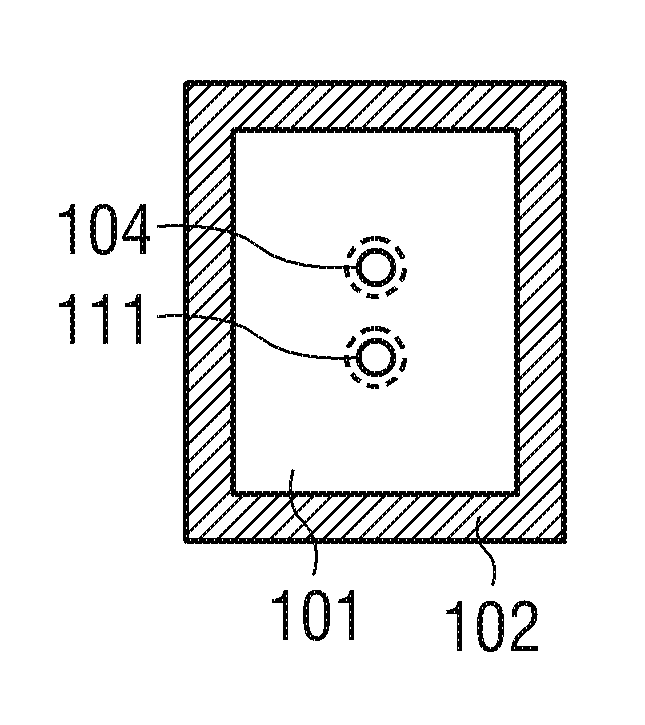

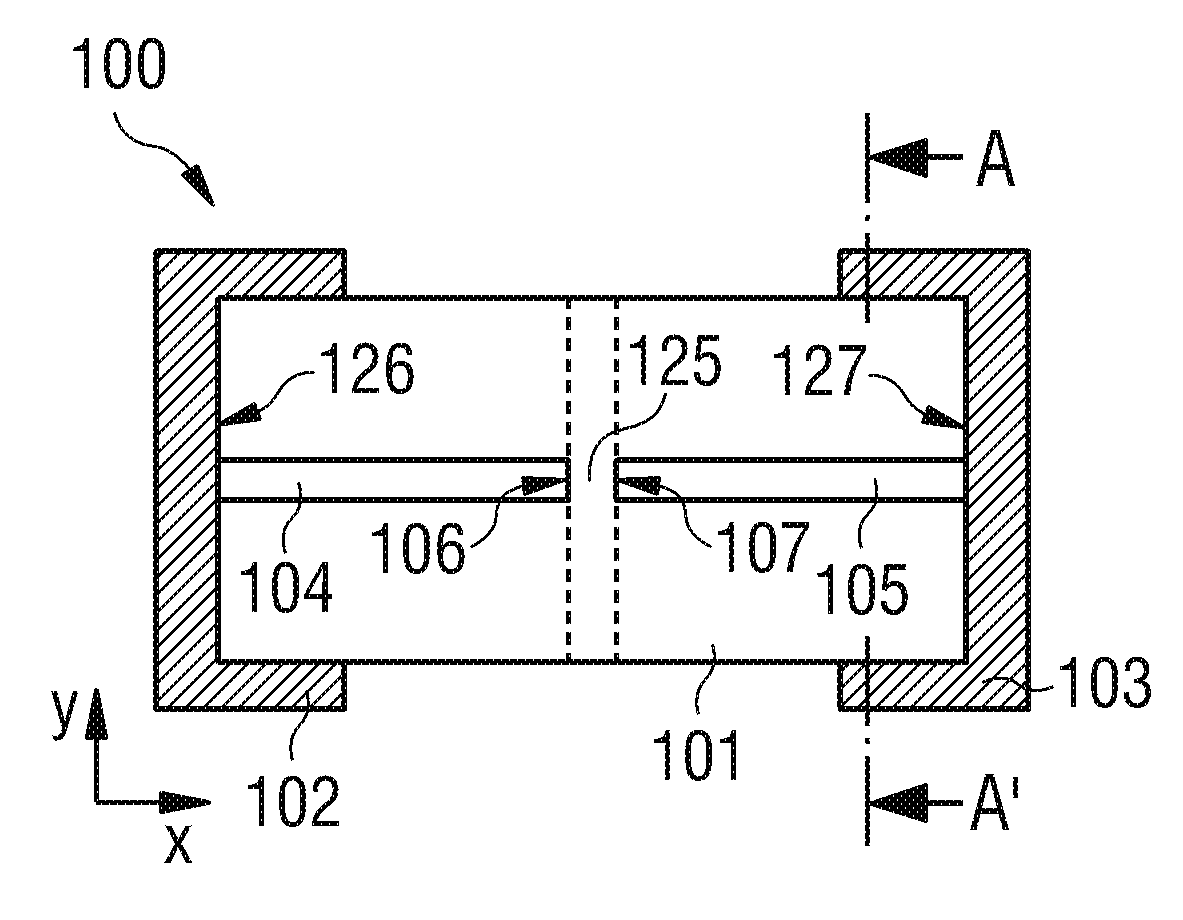

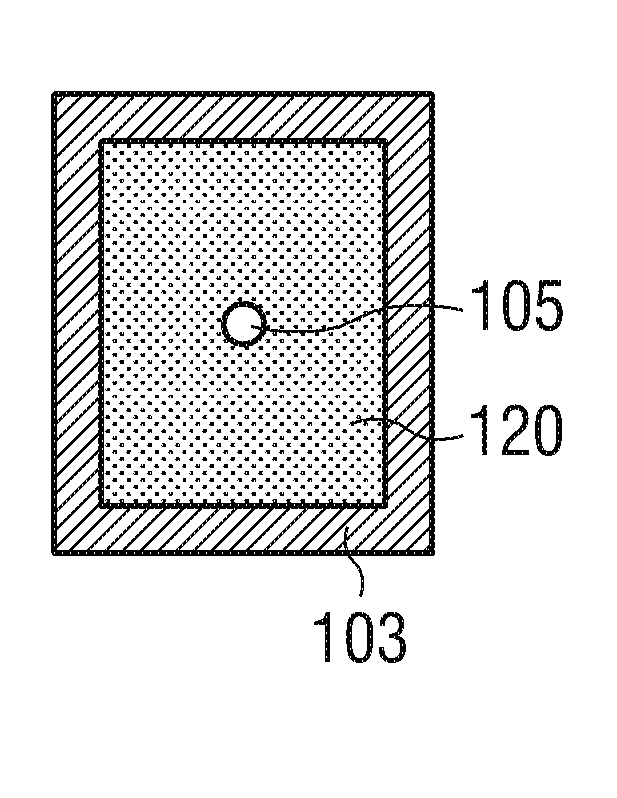

[0022] FIG. 1A shows a ceramic device 100 in cross-sectional view. The ceramic component has a base body 101 which consists of ceramic layers. Connecting contacts 102 , 103 for electrical contacting with component 100 are mounted on two opposite sides 126 , 127 . The longitudinally extending via electrodes 104 extend from the side surface 126 into the base body 101 . A further via electrode 105 extends into the base body 101 starting from the side surface 127 . The via electrode extends as far as the active region 125 in which, for example, a varistor ceramic is arranged. Via electrodes 104 and 105 respectively have faces 106 and 107 extending perpendicular to the longitudinal direction at ends facing away from connection contacts 102 and 103 respectively, which are electrically coupled to via electrodes 104 and 105 respectively.

[0023] The ceramic layers of the base body 101 are arranged in a layer stack. The layers extend planarly in the Y direction of FIG. 1 and are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com