Structure for output-stage film capacitor in power conditioner

A film capacitor and power regulator technology, applied in capacitors, irreversible DC power input conversion to AC power output, photovoltaic power generation, etc., can solve the problems of film damage, insulation breakdown, and high internal pressure of film capacitor components. To achieve the effect of preventing heat generation or capacitance reduction, and preventing abnormal breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

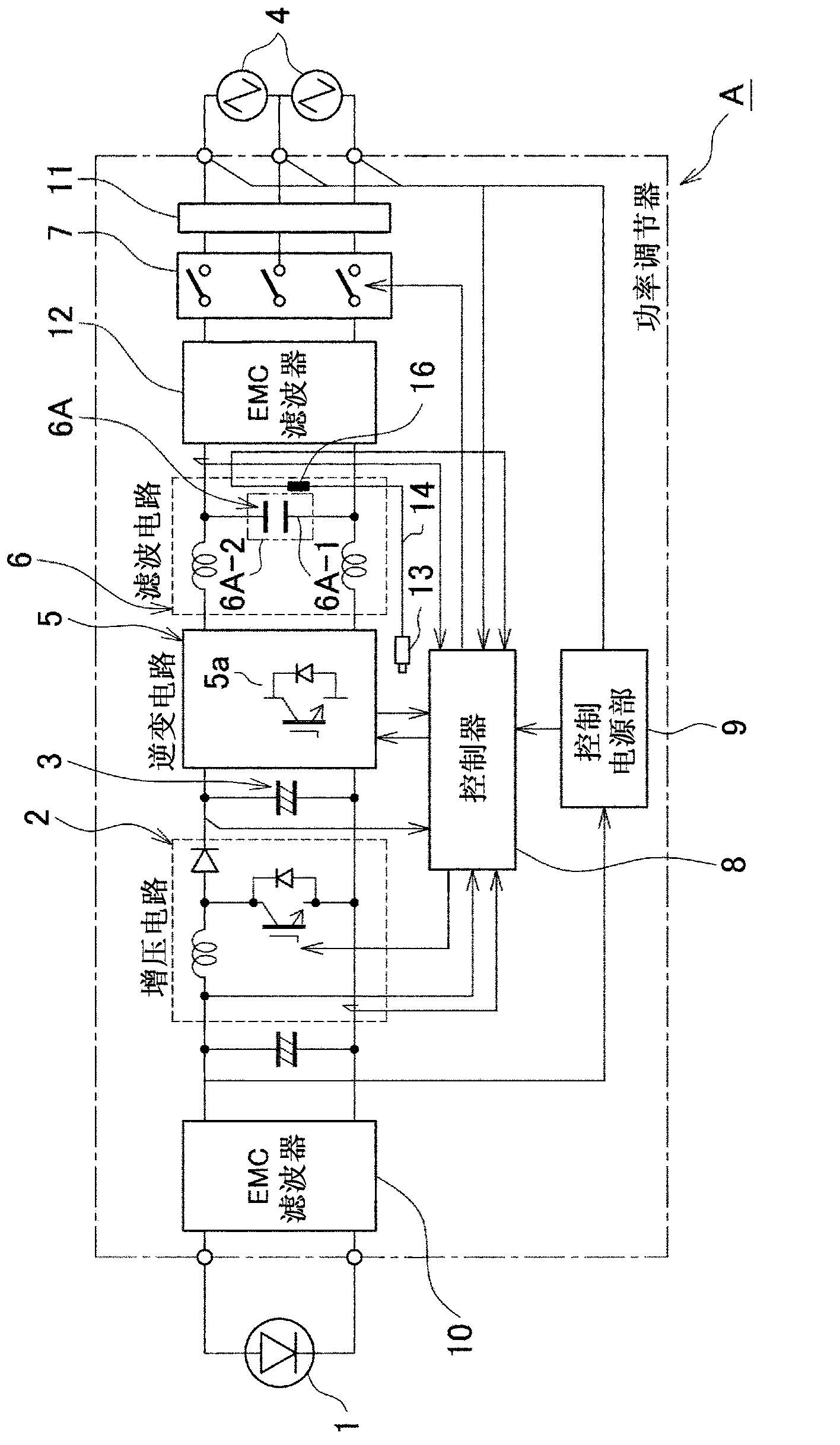

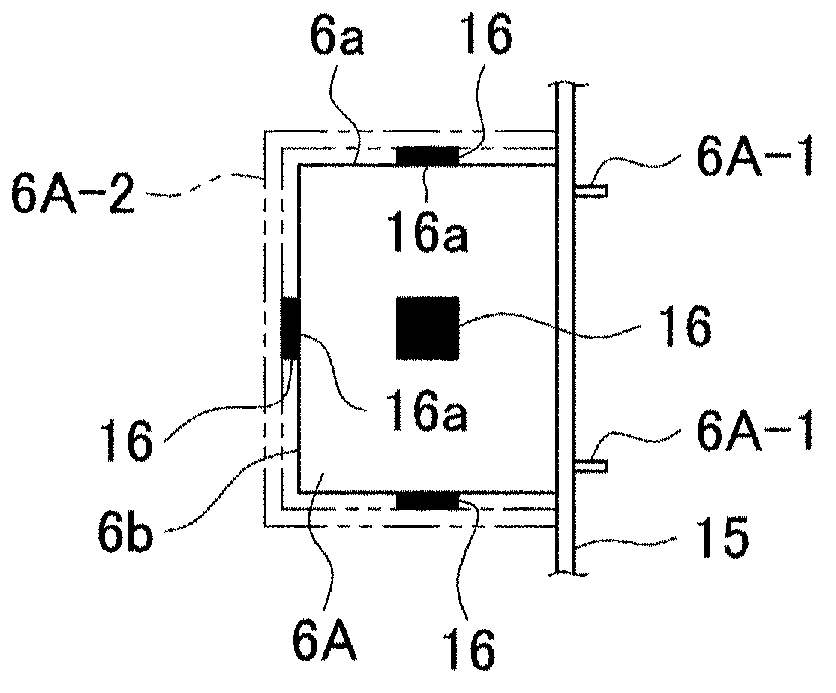

[0042] Next, we will use Figure 1 to Figure 4 A first embodiment according to the present invention will be described. In the following description, the same reference numerals will be used to describe the Figure 5 The corresponding structure of the conventional technology is shown.

[0043] Such as figure 1 As shown, a power conditioner A that converts DC power from a power source (such as the distributed power source according to the first embodiment of the present invention) into AC power synchronous with the system power supply has: DC power (such as a distributed power source); electrolytic capacitor 3, which smoothes the DC power increased in the booster circuit 2; inverter circuit 5, which converts the DC power smoothed in the electrolytic capacitor 3 into synchronization with the system power supply 4 the AC power; the filter circuit 6, which applies filter processing to the AC power converted in the inverter circuit 5; the interconnection relay 7, which blocks th...

Embodiment approach 2

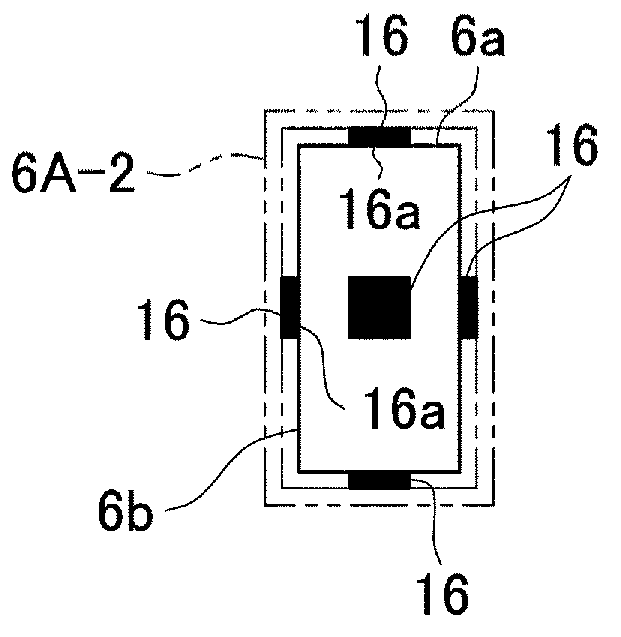

[0060] Next, we will use Figure 4 A second embodiment according to the present invention will be described. according to Figure 4 , the second embodiment has a structure similar to that of the first embodiment in which the thermal fuse 16 is directly attached to the short-side forming side 6a and the long-side forming side 6b of the film capacitor element 6A or the like, except that For example, two film capacitor elements 6A are housed in a capacitor case 6A-2 with one side surfaces adjoining each other to increase the capacitance of the capacitor, and one thermal fuse 16 is sandwiched and mounted between the two adjacent ones. between the side surfaces. Further, in the temperature sensor connection circuit 14 in the power conditioner A, the temperature fuse 16 is connected in series as in the first embodiment.

[0061]Therefore, in the second embodiment, as in the first embodiment, since the temperature fuse 16 is directly attached to the film capacitor element 6A to se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com