Natural whitening pearl barley flour as well as preparation method and application thereof

A technology of barley powder and natural beauty, which is applied in the direction of pharmaceutical formulas, cosmetic preparations, dressing preparations, etc. It can solve the problems of unsatisfactory whitening effect, achieve remarkable whitening effect, ensure safety, and use safe materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

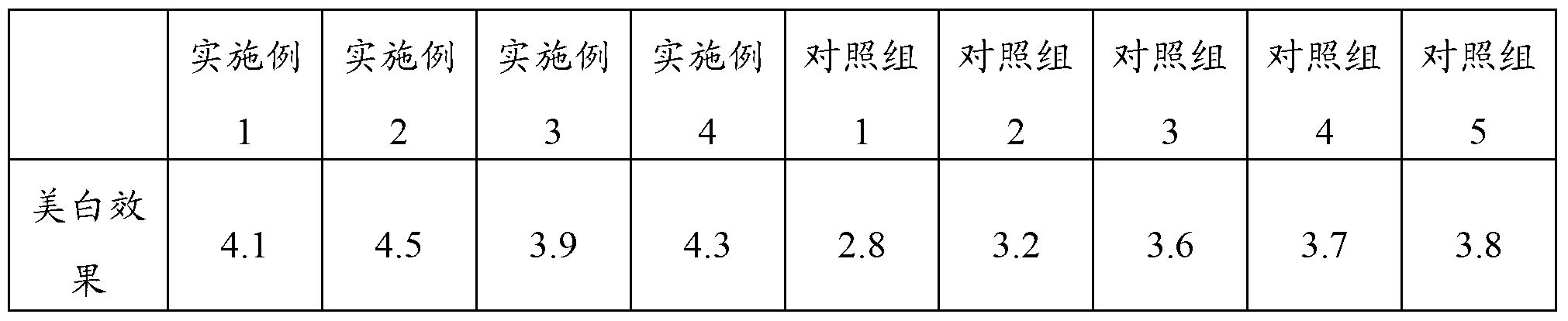

Examples

Embodiment 1

[0032] Embodiment 1: Preparation of natural whitening barley powder of the present invention

[0033] Seed of Job's tears, pearl, ginseng and white poria cocos obtain four kinds of raw material powders according to the following methods respectively:

[0034] Clean and remove impurities, rinse with running water, dry, and then crush to a particle size of 60 mesh (0.246mm). Add an appropriate amount of water and mix evenly, and place it in a sealed container for 2-4 hours to fully mix the water to obtain a coarse powder. Under the condition that the moisture content of the coarse powder is 18%, the extrusion temperature is 150°C, and the screw speed is 33Hz, it is extruded and puffed, then dried in vacuum, and pulverized for 5 minutes to obtain the raw material powder.

[0035] According to the following proportions by weight, the four raw material powders obtained above are mixed with the natural whitening barley powder:

[0036] 50 parts by weight of barley raw material pow...

Embodiment 2

[0037] Embodiment 2: Preparation of natural whitening barley powder of the present invention

[0038] Seed of Job's tears, pearl, ginseng and white poria cocos obtain four kinds of raw material powders according to the following methods respectively:

[0039] Clean and remove impurities, rinse with running water, dry, and then crush to a particle size of 60 mesh (0.246mm). Add an appropriate amount of water and mix evenly, and place it in a sealed container for 2-4 hours to fully mix the water to obtain a coarse powder. Under the condition that the moisture content of the coarse powder is 18%, the extrusion temperature is 150°C, and the screw speed is 33Hz, it is extruded and puffed, then dried in vacuum, and pulverized for 5 minutes to obtain the raw material powder.

[0040] According to the following proportions by weight, the four raw material powders obtained above are mixed with the natural whitening barley powder:

[0041] 40 parts by weight of barley raw material pow...

Embodiment 3

[0042] Embodiment 3: Preparation of natural whitening barley powder of the present invention

[0043] Seed of Job's tears, pearl, ginseng and white poria cocos obtain four kinds of raw material powders according to the following methods respectively:

[0044]Clean and remove impurities, rinse with running water, dry, and then crush to a particle size of 60 mesh (0.246mm). Add an appropriate amount of water and mix evenly, and place it in a sealed container for 2-4 hours to fully mix the water to obtain a coarse powder. Under the condition that the moisture content of the coarse powder is 18%, the extrusion temperature is 150°C, and the screw speed is 33Hz, it is extruded and puffed, then dried in vacuum, and pulverized for 5 minutes to obtain the raw material powder.

[0045] According to the following proportions by weight, the four raw material powders obtained above are mixed with the natural whitening barley powder:

[0046] 20 parts by weight of barley raw material powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com