The wire-wound filter head is easy to be damaged. When the steel wire is wound, it needs to be fixed on the frame by

spot welding. The

welding deformation is large, the strength of the steel wire is low, and it is easy to deform. The gap between the steel wire and the steel wire is difficult to control.

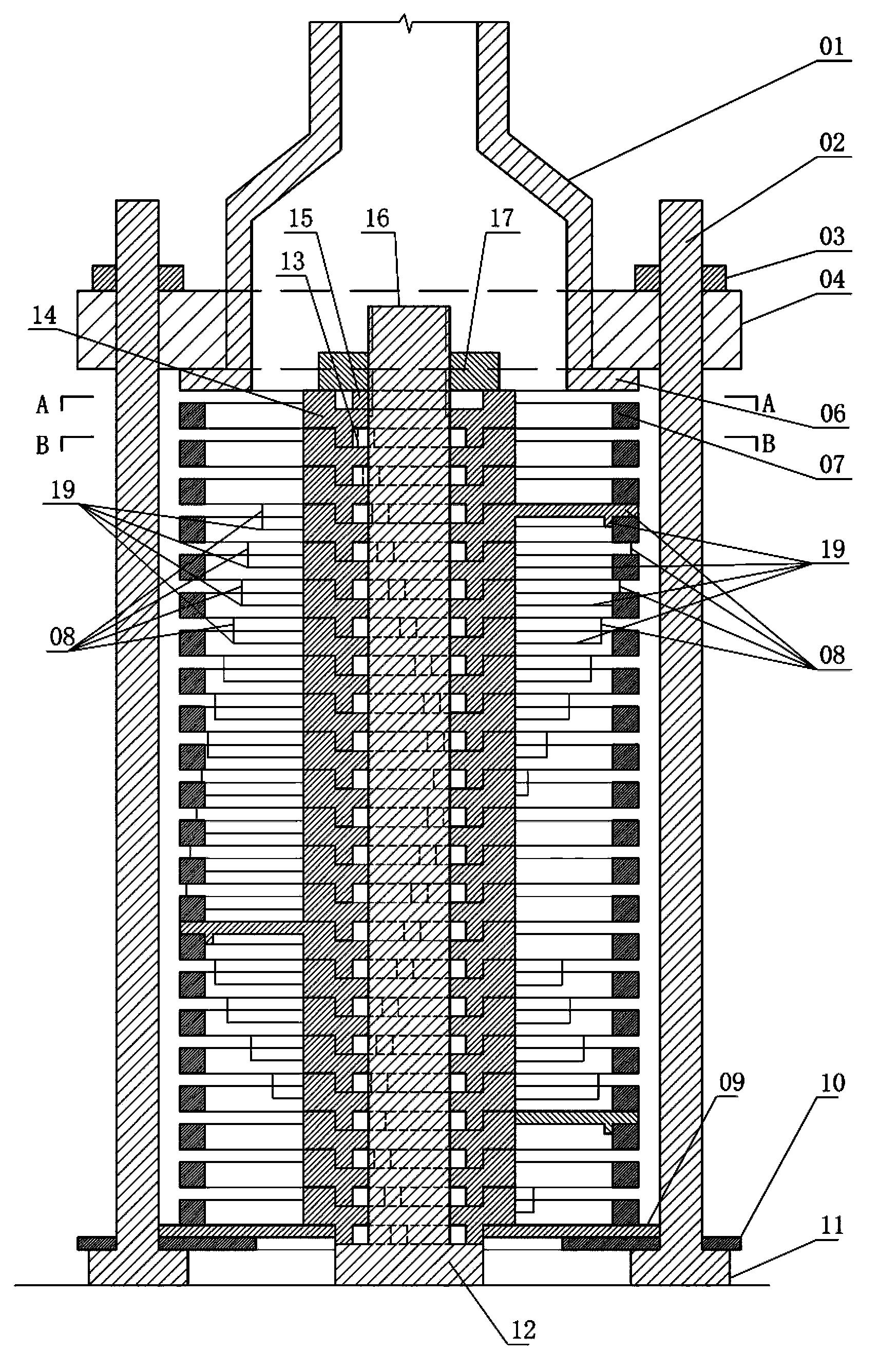

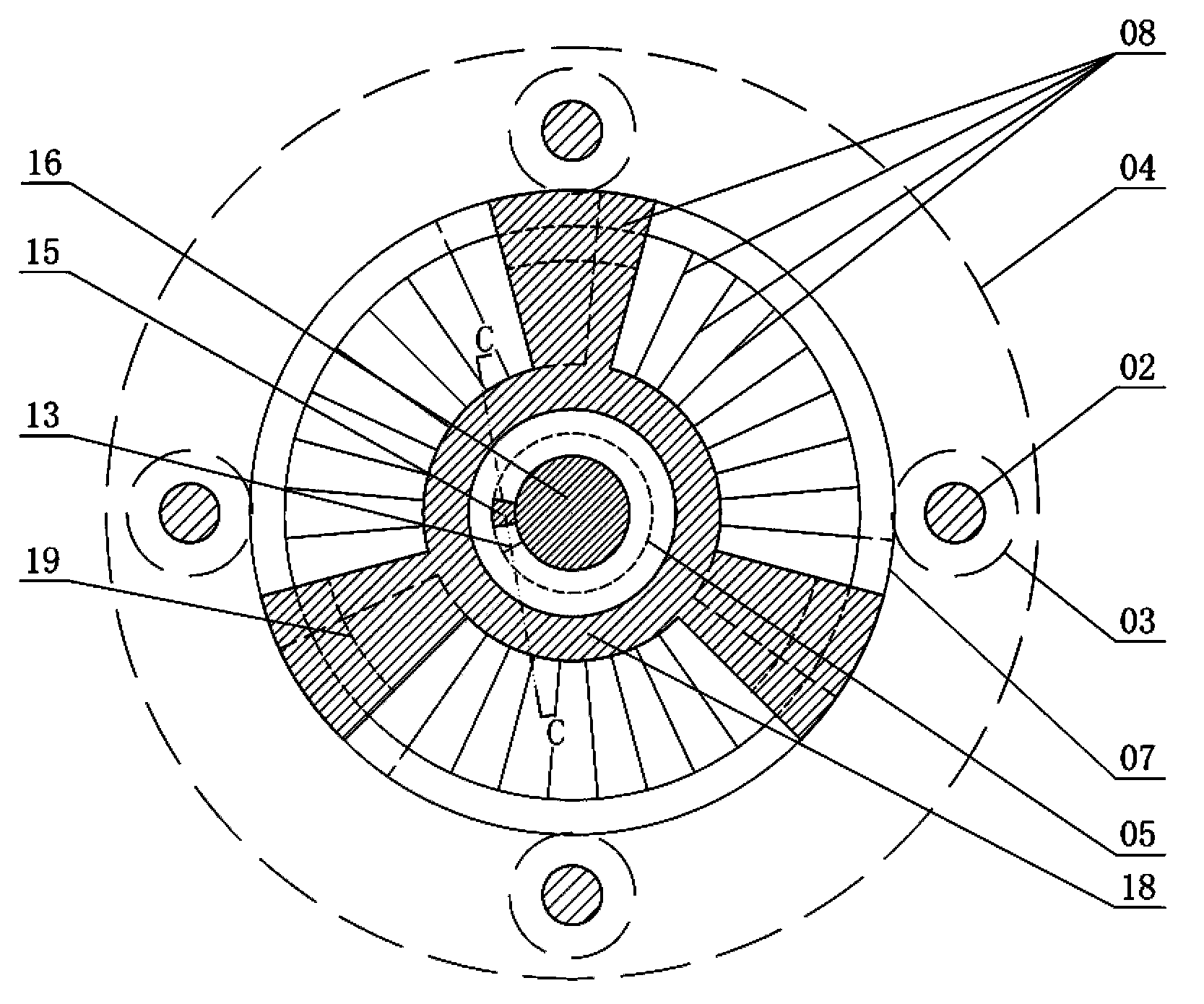

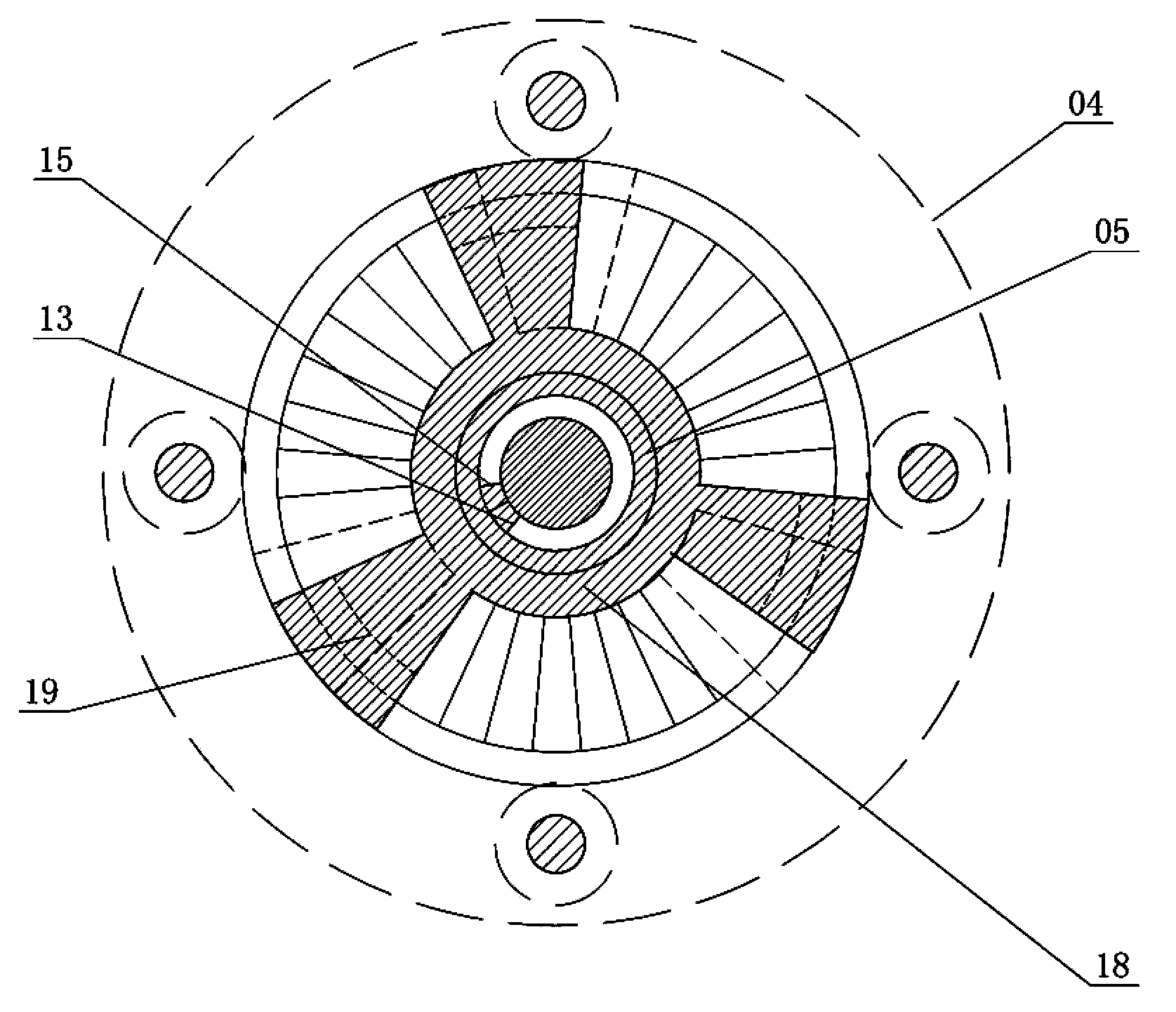

The filter tube of the laminated filter head is composed of several filter sheets with the same structure. Each filter sheet has a symmetrical small boss in the cross direction, which is integrated with the filter sheet. Therefore, after several sheets are stacked and combined Four ribs are formed in the axial direction, and four water passage gaps are formed at

equidistant intervals along the circumference between the connected two pieces. This device is not easy to be damaged compared with the wire-wound filter head. Its disadvantages are:

[0004] 1. Since the height of the small bosses is prone to deviation during production, and the

water gap between the sheets is controlled by the contact of the small bosses at four parts, this will make the size of the

water gap uneven, If the gap is too large, the

ion exchange resin will be lost.

[0005] 2. Since there are four small bosses between every two adjacent filter pieces, this also reduces the water permeability of the filter head

[0007] 1. The

processing procedure of the filter tube is cumbersome, and the

processing precision is very high, and the

processing difficulty is relatively high;

[0008] 2. Due to the vibration of the long-term

water flow impact on the filter, individual filters will be fatigued and broken under repeated high-frequency bending

Due to the limited length of the filter head, increasing the thickness of the filter will undoubtedly reduce the number of water gaps, which will greatly reduce the water permeability of the filter head and reduce the use efficiency of the device

[0009] 3. In the above scheme, all the filters are an inseparable whole, which brings great difficulty to the regular dismantling and washing work and greatly reduces the efficiency of dismantling and washing work

[0011] 1. Since each end piece is fixed by a pull piece and three fixed tie rods that run through the filter head of the

desalter longitudinally, this determines that the three end pieces of each layer are in the same position in the horizontal direction. Therefore, the overlapping end sheets will form three ribs in the longitudinal direction of the filter device, and the part of the filter sheet at the position of these three ribs will have stronger rigidity, while the rest of the filter sheet will not be supported by any other components. Rigidity is weak, therefore, the rigidity distribution of each filter is uneven

Under the long-term

impact of

water flow, this uneven distribution of rigidity will cause the filter to break due to long-term high-frequency vibration

This undoubtedly reduces the durability and

impact strength of the device

[0012] 2. The high-frequency vibration of the filter not only reduces the service life of the filter, but more importantly, because the elastic deformation that occurs during the vibration will change the

gap width between two adjacent filters, so that Reduced

filtration efficiency of

ion exchange resins

[0013] 3. Since the positioning rib in the above scheme is closely attached to the end of each end piece, and its

arc length exceeds the length of the end piece, on the one hand, it will block the water outlet and reduce the water outlet efficiency of the device; at the same time, The positioning ribs can only limit the horizontal position of the end piece, but the three tie rods already have this function. Therefore, the existence of the positioning ribs also causes waste of materials

Increased manufacturing cost of the device

[0014] 4. Since each sheet body composed of an end piece and a tie piece must simultaneously and accurately set its three collar pieces on the three tie rods that form a dynamic cooperation relationship with it, it has a high

assembly accuracy requirement , so the

assembly process is not efficient

[0015] 5. In this device, the alternately superimposed filter pieces and end pieces are pressed tightly, relying on three tie rods located in the middle of the device, and there is no force-applying structure at the outer edges of the end pieces and filter pieces to make them The edge is tightly combined, and such uneven force will lead to a difference in the height position between the middle and the edge of the sheet body composed of the end sheet and the tie sheet, thereby causing a certain degree of deformation, and this deformation is for the adjacent filter The uniformity of the gap between the sheets is very unfavorable

thus also reducing the filtering effect of the unit

[0016] 6. In this device, due to the blockage of the top plate at the water inlet, the water can only pass through the three limited-area water holes opened on the top plate, which undoubtedly reduces the water passing efficiency of the device; but if the three The opening area of the water hole will inevitably reduce the strength of the top plate, affecting its pressure and fixing effect on the filter piece and end piece, which is also a pair of difficult contradictions

Login to View More

Login to View More  Login to View More

Login to View More