Integrated precision grinding system and method for extra-large spherical surface

A precision grinding, extra-large technology, used in spherical grinders, grinding/polishing equipment, grinders, etc., can solve the problems of large size and heavy weight, and achieve the effect of improving efficiency, good surface roughness and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with embodiment.

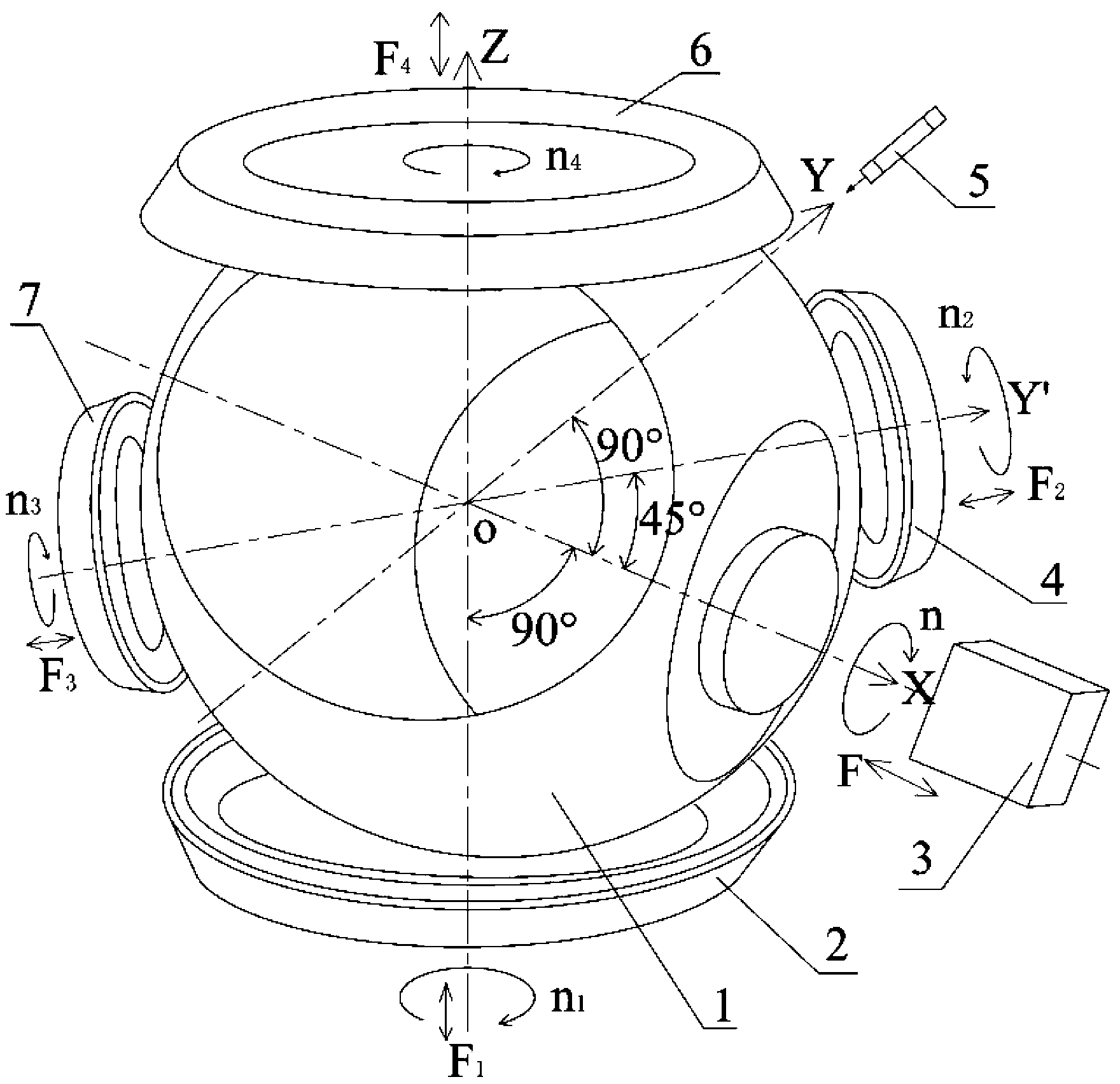

[0020] like figure 1 As shown, the extra-large spherical surface integrated precision grinding system of the present invention includes: a sphere driving part 3, a first grinding wheel abrasive 2, a second grinding wheel abrasive 4, a third grinding wheel abrasive 7, a grinding abrasive 6 and a detection component 5. They are in the same X, Y, Z rectangular coordinate system, the X, Y, Z rectangular coordinate system includes the origin O, the horizontal coordinate axis X, the horizontal coordinate axis Y and the vertical coordinate axis Z. The sphere center of the ground sphere 1 of the super-large spherical surface coincides with the origin O, and in the X, Y, Z rectangular coordinate system, the rotation center line of the sphere driving part 3 coincides with the horizontal coordinate axis X, and the first grinding wheel The rotation center line of tool 2 and the rotation center lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com