Ammonia compressor starting method with reduced ammonia consumption

A technology of an ammonia compressor and a start-up method, applied in the field of synthetic ammonia production, can solve the problems of increasing the start-up cost of a compressor unit, increasing the start-up cost of an ammonia compressor unit, ammonia loss, etc., so as to shorten the gas ammonia venting time, save production costs, and reduce ammonia. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

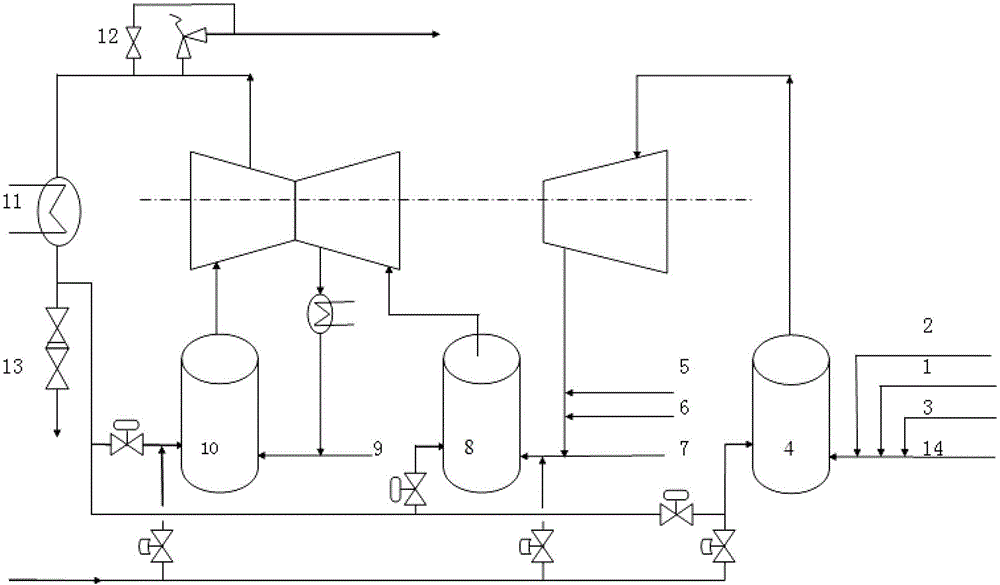

[0017] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0018] Such as figure 1 , low-temperature methanol washing I14 and the ammonia flash tank 1 of the refrigeration system, the inert gas cooler 2 and the third ammonia cooler 3 of the ammonia synthesis circuit. Finally, after being mixed with the gas ammonia of the second ammonia cooler 5 of the ammonia synthesis circuit, the air separation ammonia cooler 6, and the low-temperature methanol washing II 7, it enters the second stage inlet separator 8 of the ammonia compressor, and after being compressed by the second stage of the ammonia compressor, The gaseous ammonia mixed with the first ammonia cooler 9 of the ammonia synthesis circuit enters the three-stage inlet separator 10 of the ammonia compressor, is compressed by the ammonia compressor in three stages, is cooled by the anti-kick c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com