Polyurethane grouting material and preparation method thereof

A grouting material, polyurethane technology, applied in the directions of reagents, educts, products, etc., can solve the problems of residual free TDI, environmental hazards, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

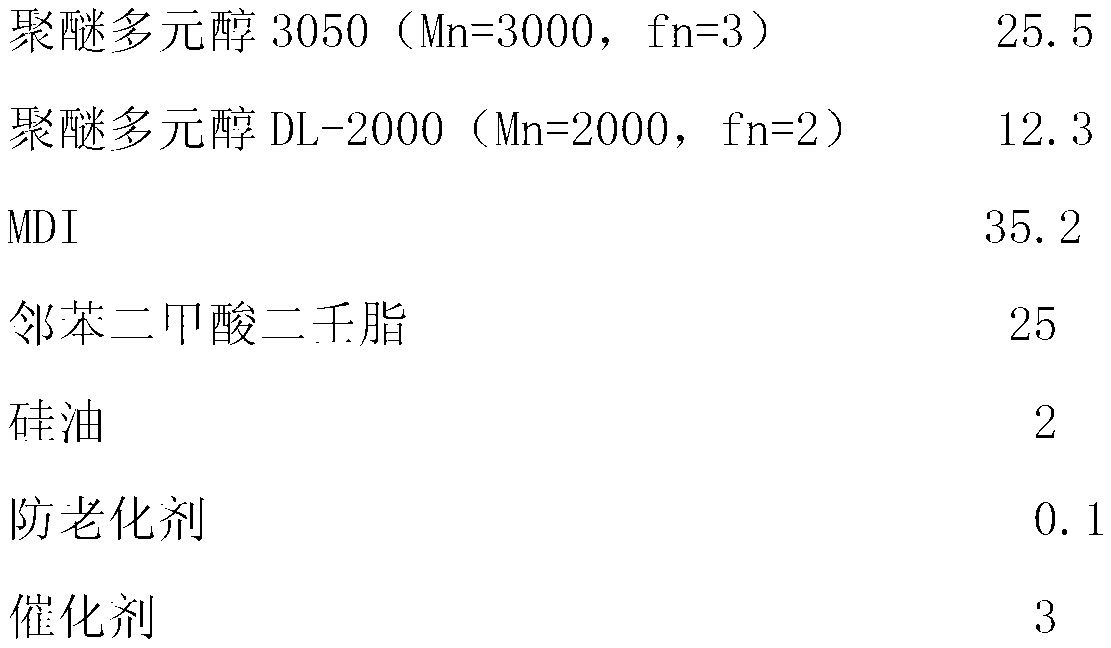

Embodiment 1

[0024]

[0025] The preparation method of one-component polyurethane grouting material is as follows:

[0026] In the interlayer reaction kettle, add polyether polyol and dioctyl phthalate according to the formula, dehydrate for 2 to 3 hours at a temperature of 110-120°C and a vacuum of -0.1MPa, and cool down to 60 ℃, add small molecule chain extender, stir evenly, add MDI, slowly raise the temperature to 85°C, react for two hours, cool down to below 30°C, add additives, stir evenly, then discharge, fill with nitrogen and seal the package. When using, open the package and use directly.

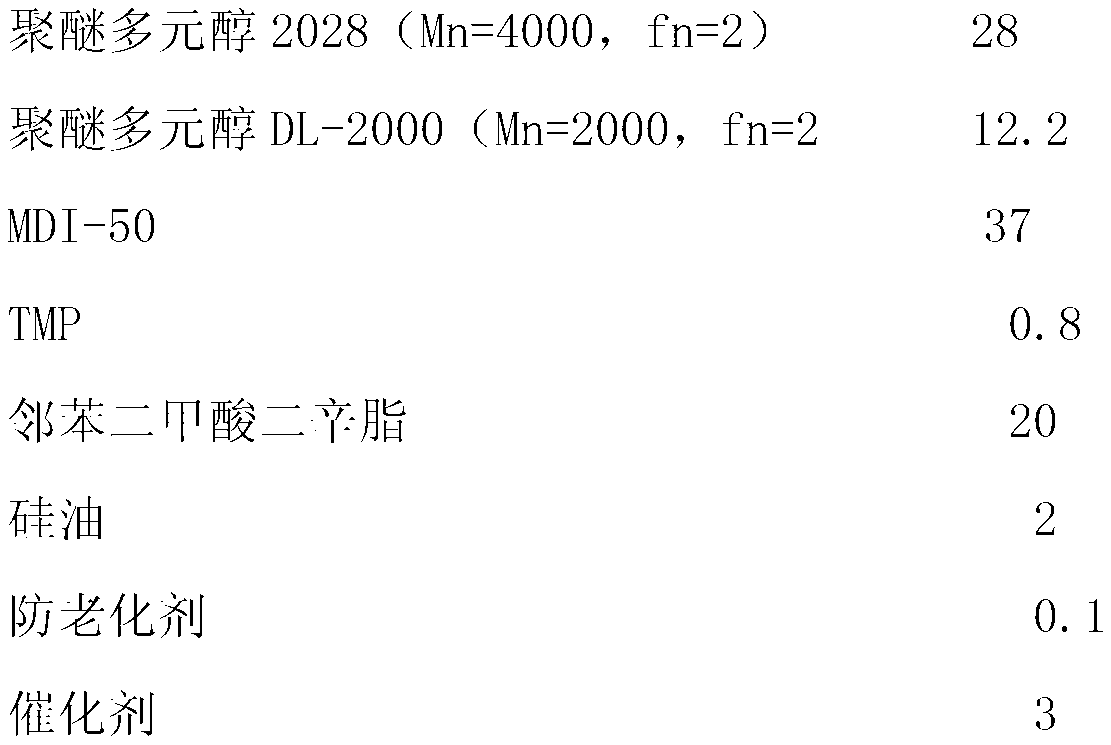

Embodiment 2

[0028]

[0029] The preparation method of one-component polyurethane grouting material is as follows:

[0030] In the interlayer reaction kettle, add polyether polyol and dioctyl phthalate according to the formula, dehydrate for 2 to 3 hours at a temperature of 110-120°C and a vacuum of -0.1MPa, and cool down to 60 ℃, add MDI-50, slowly raise the temperature to 85 ℃, react for two hours, cool down to below 30 ℃, add additives, stir evenly, discharge, fill with nitrogen and seal the package. When using, open the package and use directly.

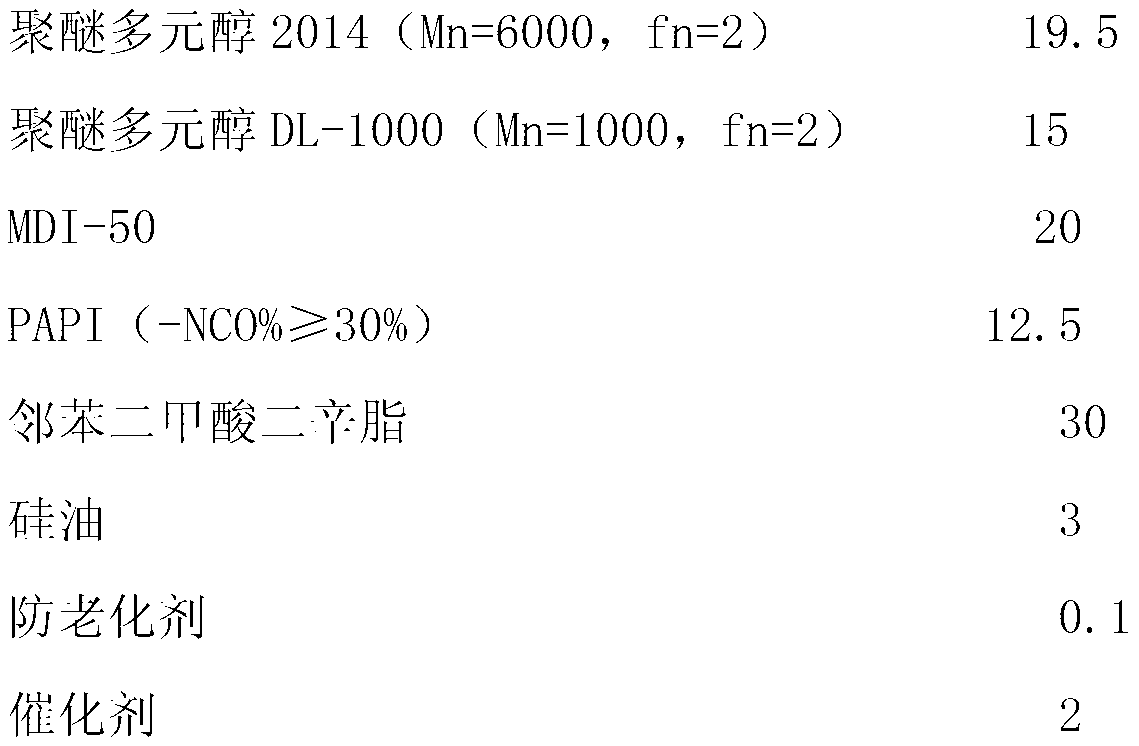

Embodiment 3

[0032]

[0033] The preparation method of one-component polyurethane grouting material is as follows:

[0034] In the interlayer reaction kettle, add polyether polyol and dioctyl phthalate according to the formula, dehydrate for 2 to 3 hours at a temperature of 110-120°C and a vacuum of -0.1MPa, and cool down to 60 ℃, add PAPI, slowly raise the temperature to 75°C, react for two hours, cool down to below 30°C, add additives, stir evenly, discharge, fill with nitrogen and seal the package. When using, open the package and use directly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com