Acidic surfactant fracture liquid system

An acidic surface and active agent technology, which is applied in the field of acidic surfactant fracturing fluid system, can solve the problems affecting the stimulation effect of fracturing, dentition fracture permeability and formation permeability damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

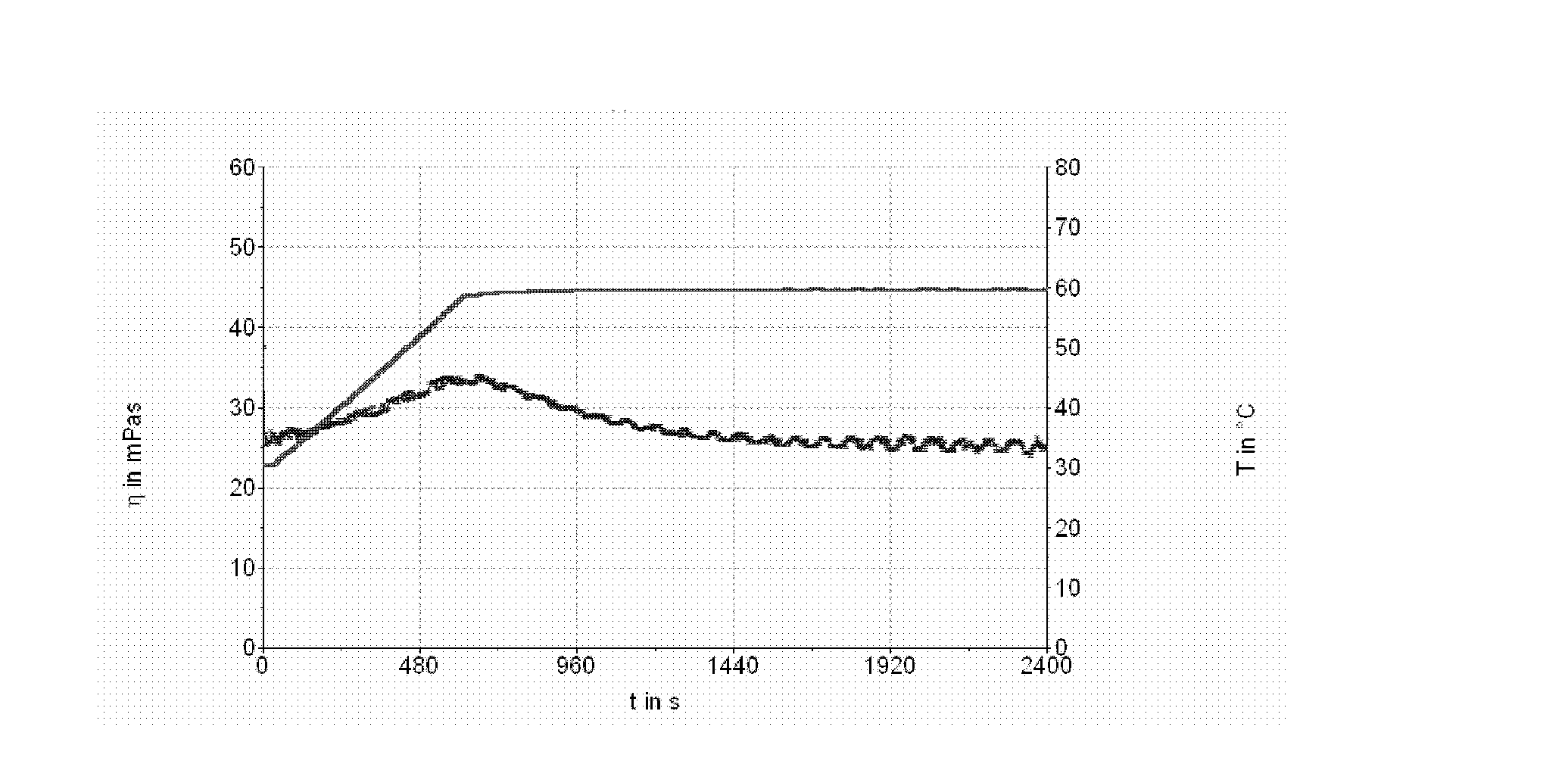

[0019] At room temperature of 25°C, 2.2g of cetyltrimethylammonium bromide and 0.8g of potassium hydrogen phthalate were sequentially added into water and stirred evenly. Then slowly add 30ml of 37% hydrochloric acid and 0.1% hydrofluoric acid mixture under stirring conditions and continue stirring for 5 minutes to prepare an acidic surfactant fracturing fluid with an initial viscosity of 40mPa·s. For the fracturing fluid at 60°C, see the temperature resistance and shear resistance of 170S-1 figure 1 .

[0020] The fracturing fluid is mixed with 1:1 water at 60°C. After breaking the gel, the viscosity of the fracturing fluid is 2.4mP·s and the surface tension is 22mN / m.

Embodiment 2

[0022] The acidic surfactant fracturing fluid was prepared according to the above steps, except that the amount of cetyltrimethylammonium bromide was 5.0 g, and the initial viscosity of the prepared acidic surfactant fracturing fluid was 80 mPa·s.

Embodiment 3

[0024] The acidic surfactant fracturing fluid was prepared according to the above steps, the different amount of potassium hydrogen phthalate was 2.5 g, and the initial viscosity of the prepared acidic surfactant fracturing fluid was 60 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com