Z-shaped steel concrete specially-shaped column provided with steel angle frame

A special-shaped column and concrete technology, applied in the direction of columns, pillars, piers, etc., can solve the problems of difficulty in vibrating, difficulty in descending coarse aggregate, and incompact concrete pouring of protective layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

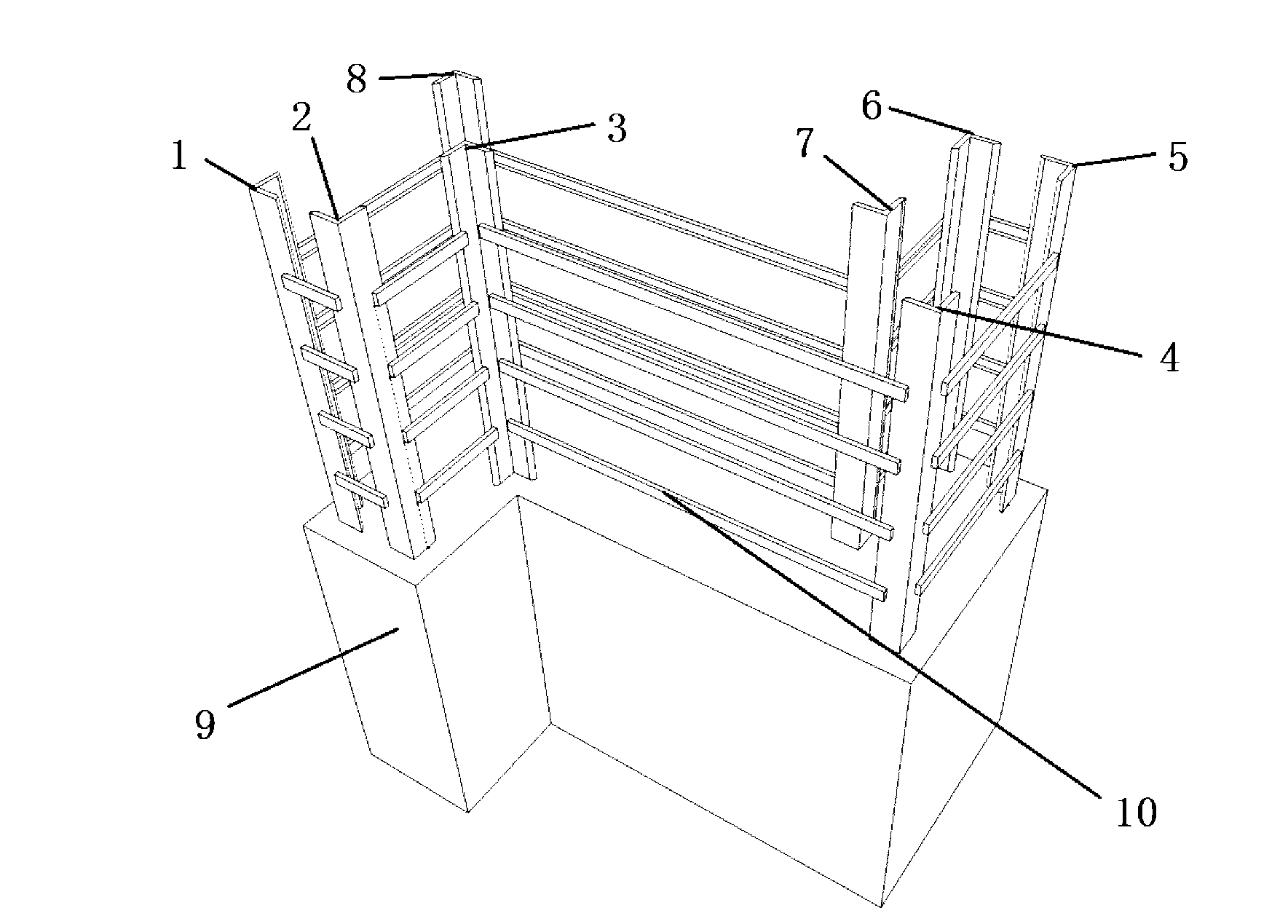

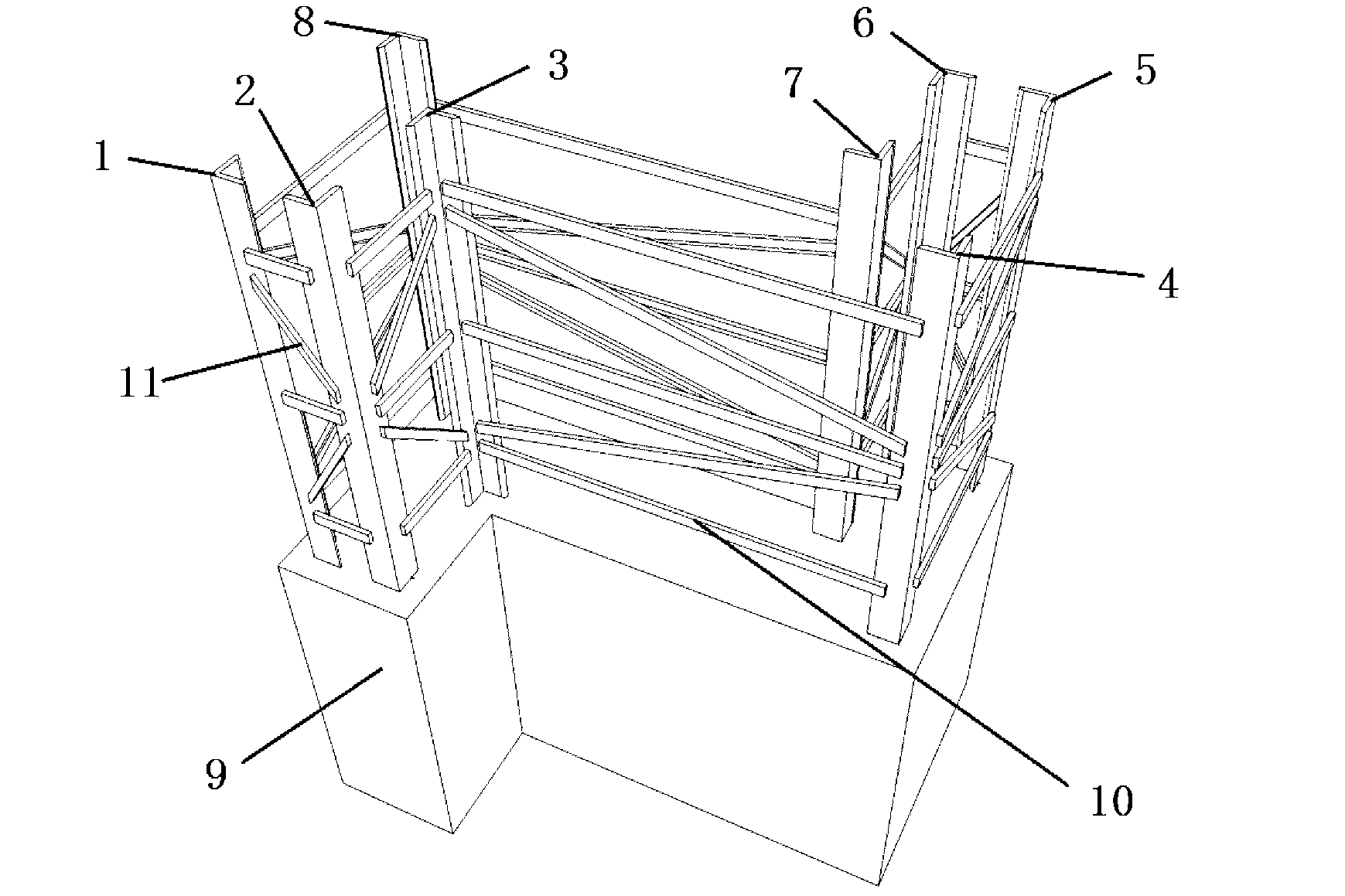

[0017] figure 1 It shows the first embodiment of the Z-shaped steel concrete special-shaped column with angle steel skeleton in the present invention. The erection of the lattice-type angle steel steel skeleton is welded by all horizontal and transverse steel accessories. Among them, angle steel one 1, angle steel two 2, angle steel four 4, angle steel five 5, angle steel six 6, and angle steel eight 8 are located at the end of each column limb of a special-shaped column with a Z-shaped cross-section, and are set with the back of the angle steel limb facing outward. The vertical distance between the surface and the outer surface of the special-shaped column limb is the thickness of the angle steel concrete protective layer; angle steel three 3 and angle steel seven 7 are located at the intersection of each column limb of the special-shaped column with a Z-shaped section and the section web, just at the corner of the section The part is set with the back of the limb facing inwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com