Fast-rotation type oil drill rod joint thread reinforcing structure

A technology for oil drill pipe joints and strengthening structures, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve problems such as unreasonable thread structures of oil drill pipe joints, reduce the probability of thread fatigue cracks, and improve torsion resistance , The effect of reducing auxiliary man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

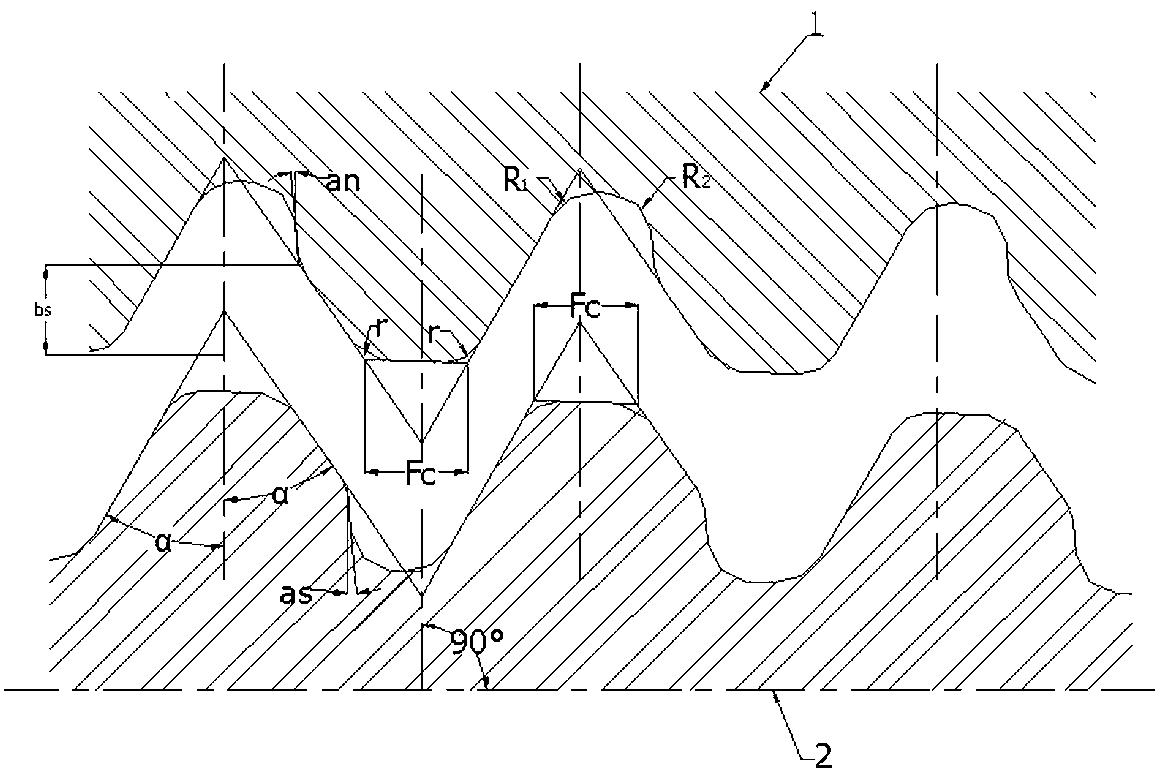

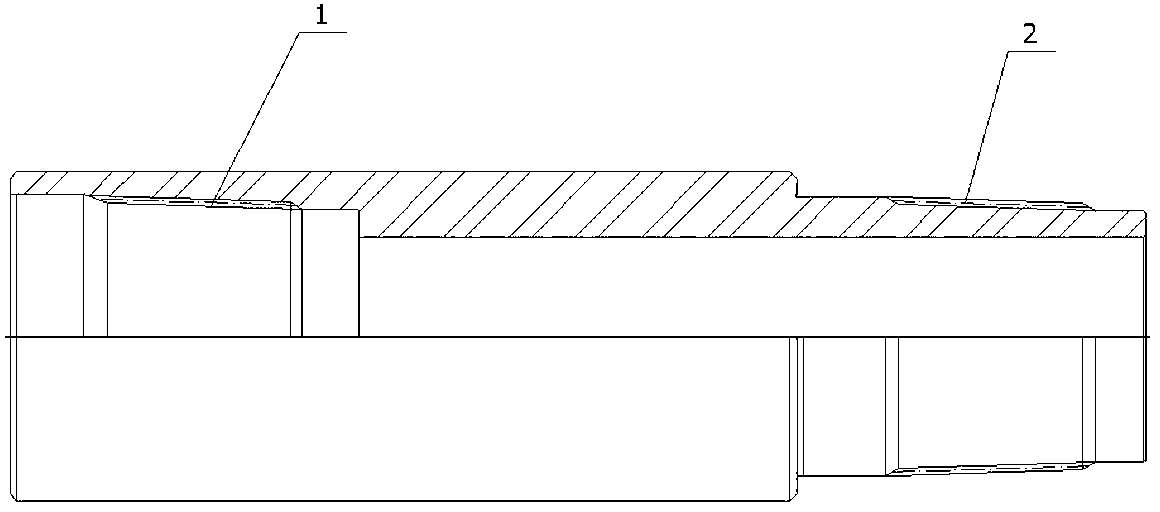

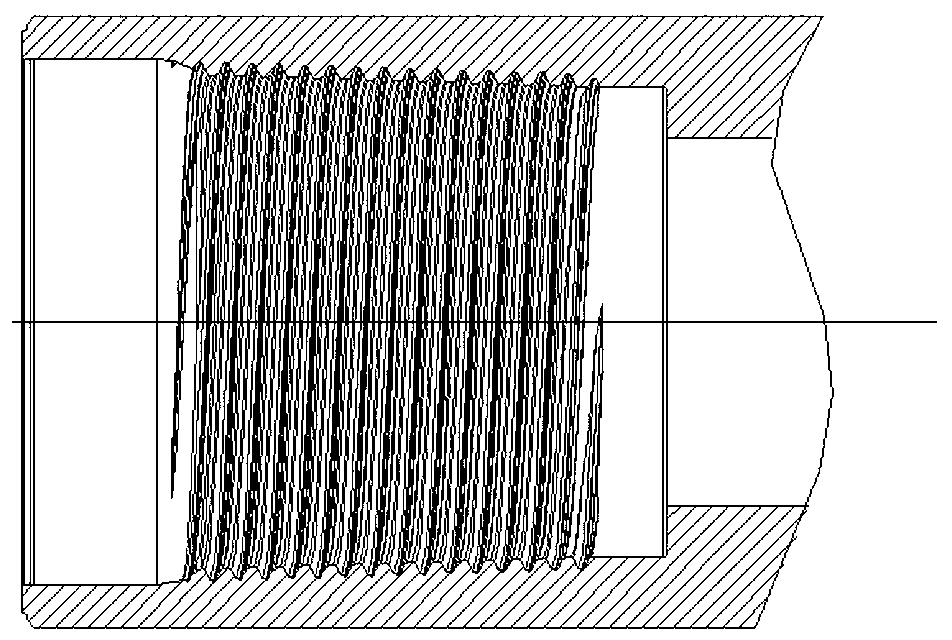

[0017] Quick-rotating oil drill pipe joint threaded structure such as figure 1 ,Such as figure 2 As shown, it is set in the taper internal thread 1 and taper external thread 2 at both ends of the oil drill pipe joint. The tapered internal thread 1 and the tapered external thread 2 have the same specifications. This embodiment is a JST55 oil drill pipe joint with a taper of 1:16. There are three threads with the same rotation direction at both ends, and each thread is on the same cross section. 120 apart 0 . Under the premise of the same specification, the lead of the three-threaded thread is larger than that of the single-threaded or double-threaded thread. In this embodiment, the connected drill pipe can be tightened by 0.58 revolutions. This kind of quick-turning structure is simple, easy to manufacture, and connect Fast and reliable, significantly improving drilling efficiency. The tooth profile of taper internal thread 1 and taper external thread 2 are the same, the axial...

Embodiment 2

[0019] The specification of this embodiment is the JST39 oil drill pipe joint. Although the specification is smaller than that of the embodiment 1, the structure of the two is exactly the same. Only the structural parameters have been adjusted. The specific parameters are shown in the main structural parameter table of the embodiment. The technical effect of the application of this embodiment is similar to that of Embodiment 1. In order to save space, it will not be repeated.

[0020] The main structural parameter table of the embodiment:

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com