Seedling stage mulching film recycling film winding roll

A film roll and mulch technology, applied in the field of agricultural machinery, can solve the problems of time-consuming picking, labor-intensive, unclean, etc., and achieve the effects of easy and quick film unloading, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

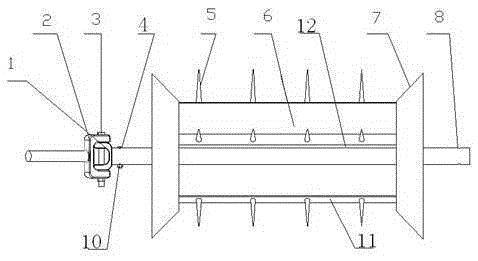

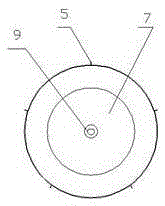

[0014] Embodiment of the present invention: a film roll for seedling mulching recovery, as shown in the accompanying drawings, includes a film roll disc shaft 8, a film roll column 11 set on the film roll disc shaft 8, and the film roll post 11 There are at least 2 roll film racks 6 surrounding the city, and a gap 12 is provided between the film roll racks 6. The two ends of the film roll racks 6 are fixed to the film roll shaft disk 7, and the film roll shaft disc 7 is a cone Structure, the rack 5 is evenly arranged on the surface of the film roll column 11, the film roll shaft disc 7 is fixedly arranged on both sides of the film roll column 11 and the film roll shaft disc 7 is fixed to the film roll disc shaft 8.

[0015] Wherein, a semicircular hole 9 is set at one end of the film roll disc shaft 8, and a connecting pin hole 4 is symmetrically arranged on the film roll disc shaft 8 at the semicircle hole 9, and one end of the universal joint 1 is inserted into the semicircle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com