Processing machine tool for integrated propeller

A technology for processing machine tools and propellers, which is applied in the direction of metal processing machinery parts, machine tool parts, metal processing equipment, etc., can solve problems such as damage to blades, material peeling, difficulty in processing blade fillets and hubs, and reduce labor intensity , Reduce operating links, save auxiliary man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

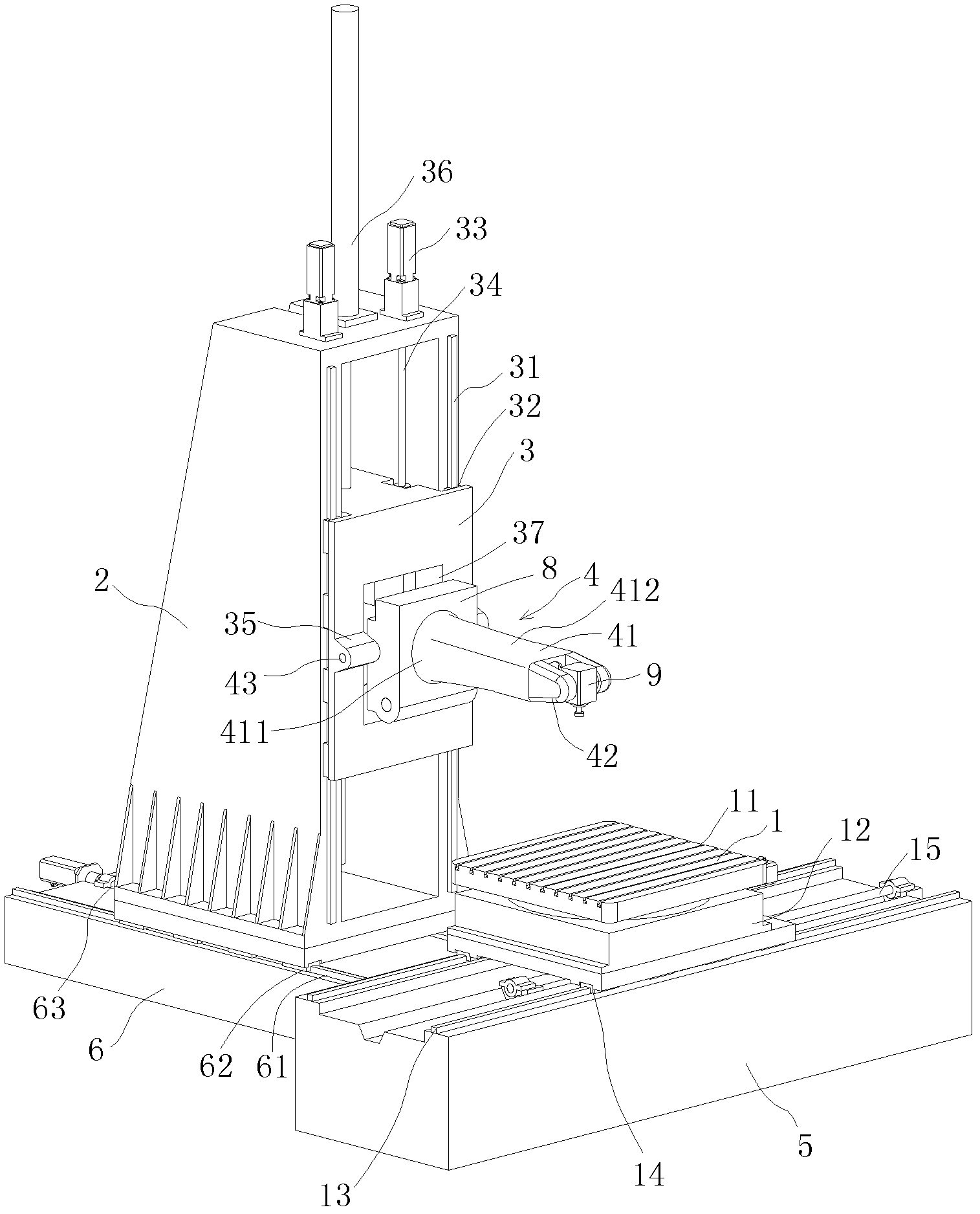

[0021] Such as figure 1 As shown, the present invention provides a kind of integral propeller processing machine tool, comprises:

[0022] The flat turntable 1, which can be rectangular or circular, is used to install workpieces. On the working surface of the flat turntable 1, there are a plurality of parallel or radially distributed T-shaped clamp grooves 11 for clamping the end face of the workpiece. The flat turntable 1 Can rotate along the vertical axis;

[0023] The frame 2 is preferably in the form of a column, which is located on one side of the turntable 1 and can be displaced relative to the turntable 1;

[0024] The frame 3 is in the form of a box and is arranged on the upright to slide up and down; and

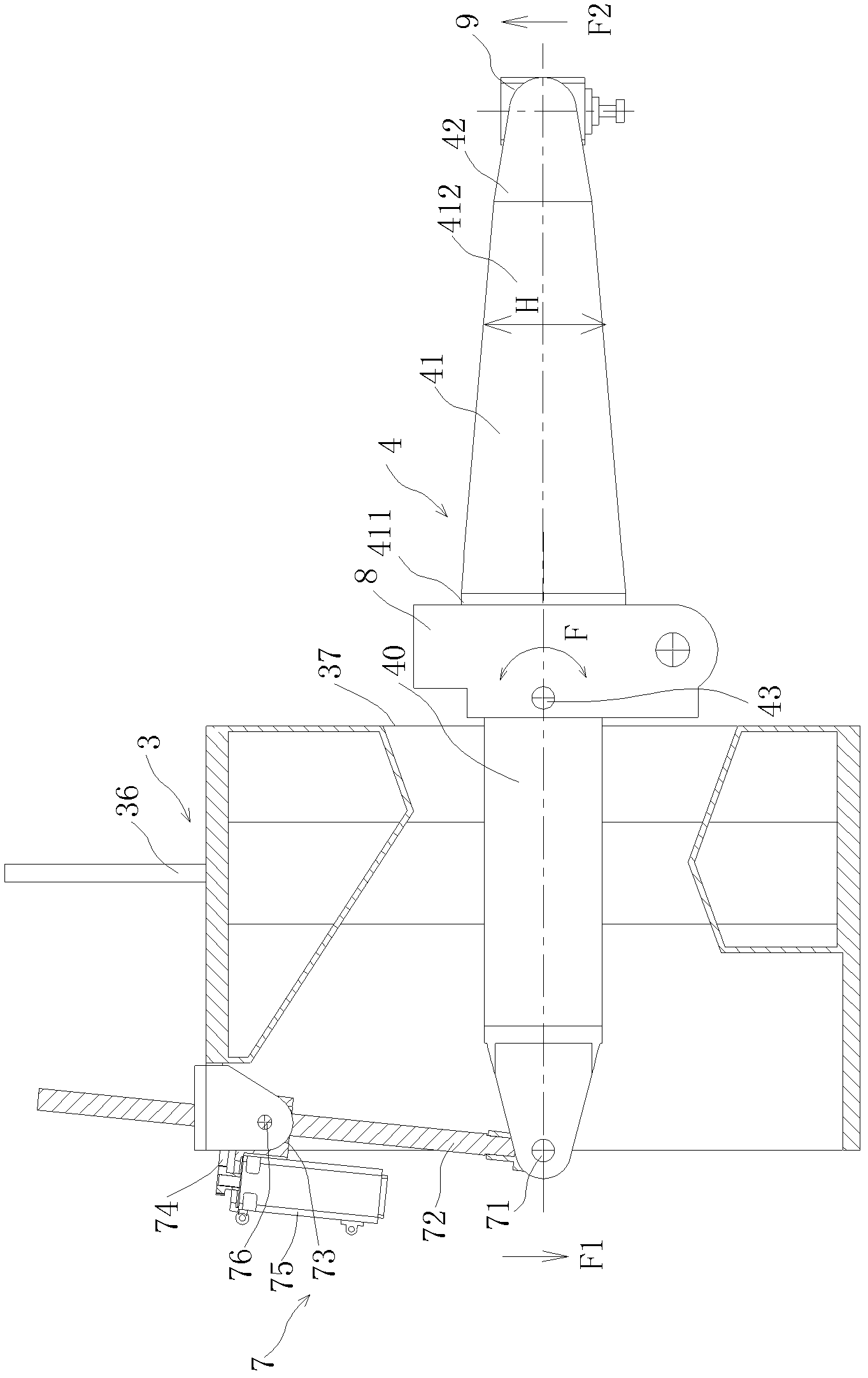

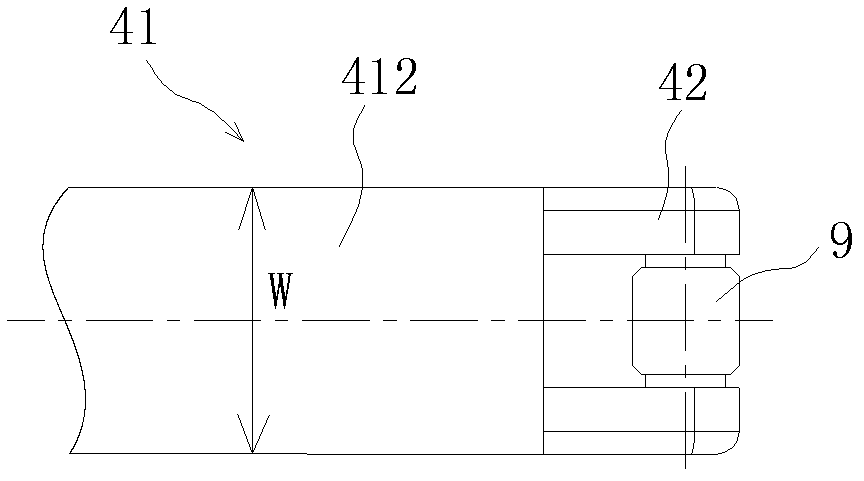

[0025] The mechanical arm 4 is located on the frame 3, passes through the frame 3 along the front-rear direction, and can swing up and down in the frame 3. The mechanical arm 4 is provided with a processing forearm 41 that can rotate around the axis of the mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com