Roadheader cutting drum

A technology for cutting drums and bolter miners, which is applied in the direction of cutting machinery, slitting machinery, driving devices, etc., can solve problems such as low driving speed, high geological conditions, and lack of intelligent control, so as to improve positioning accuracy, The effect of improving tunneling efficiency and optimizing tunneling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

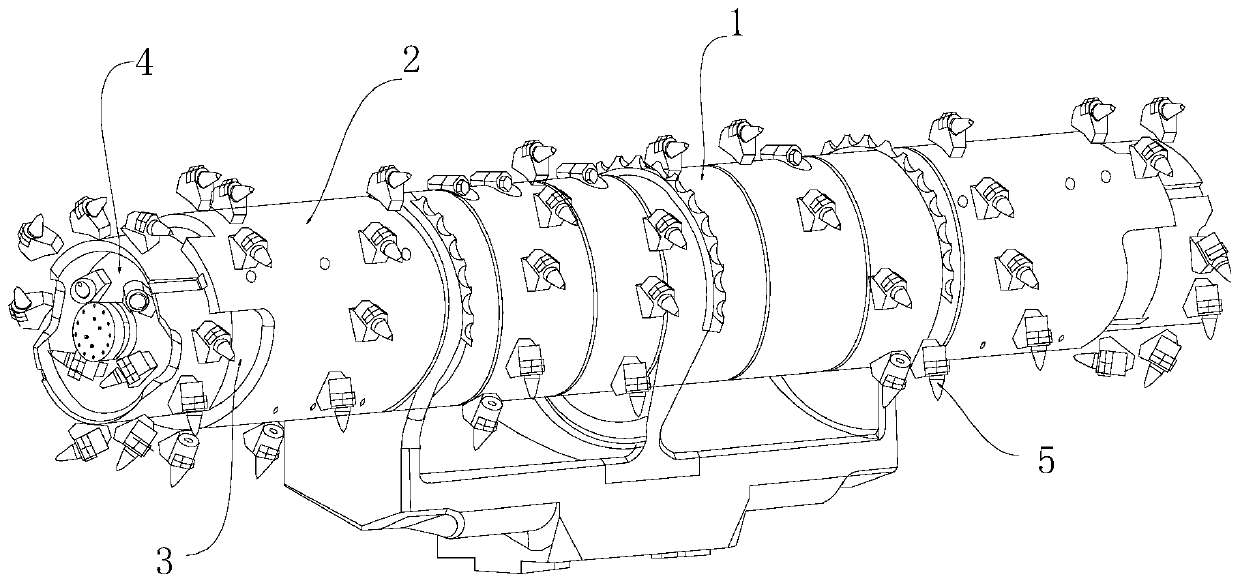

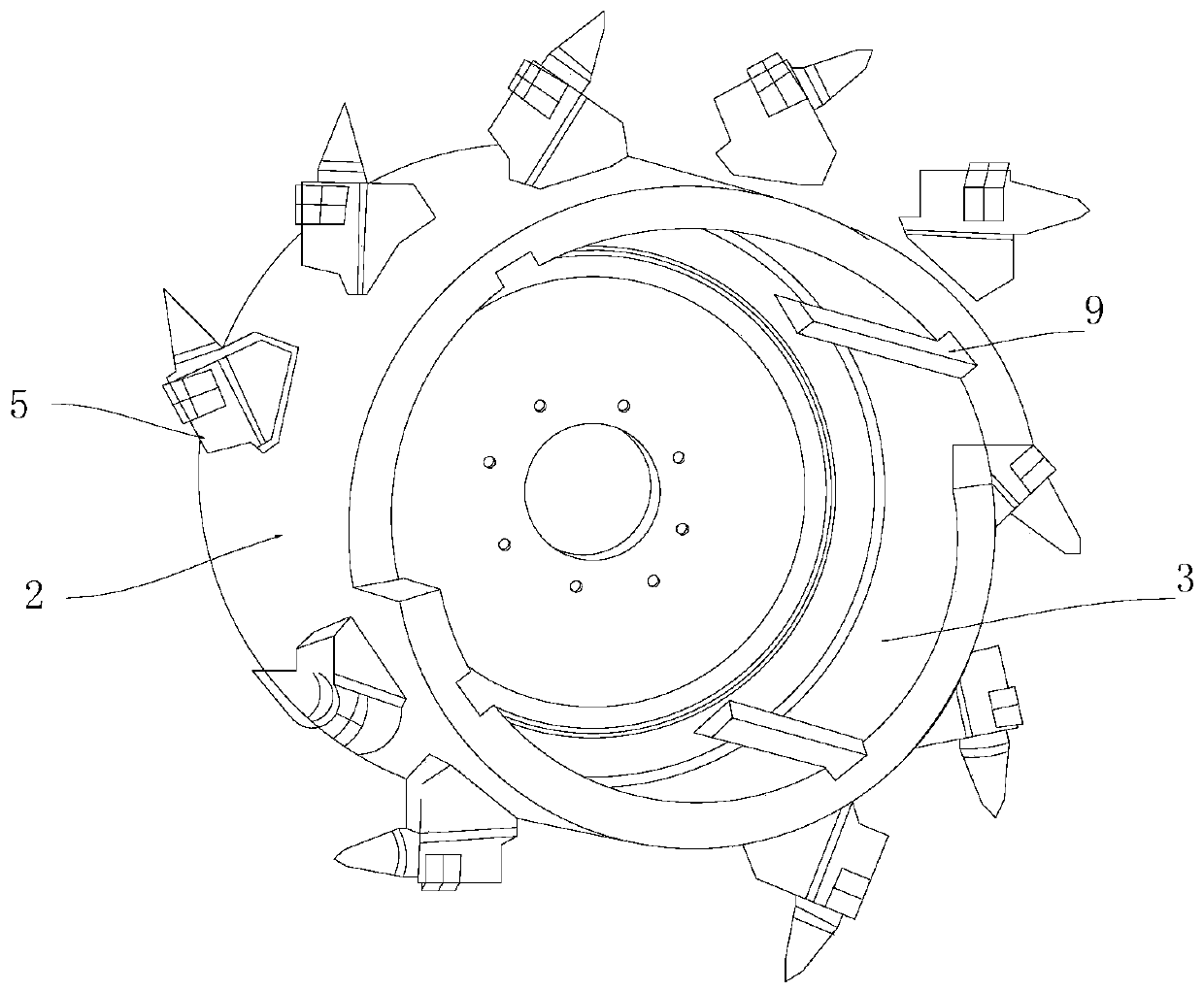

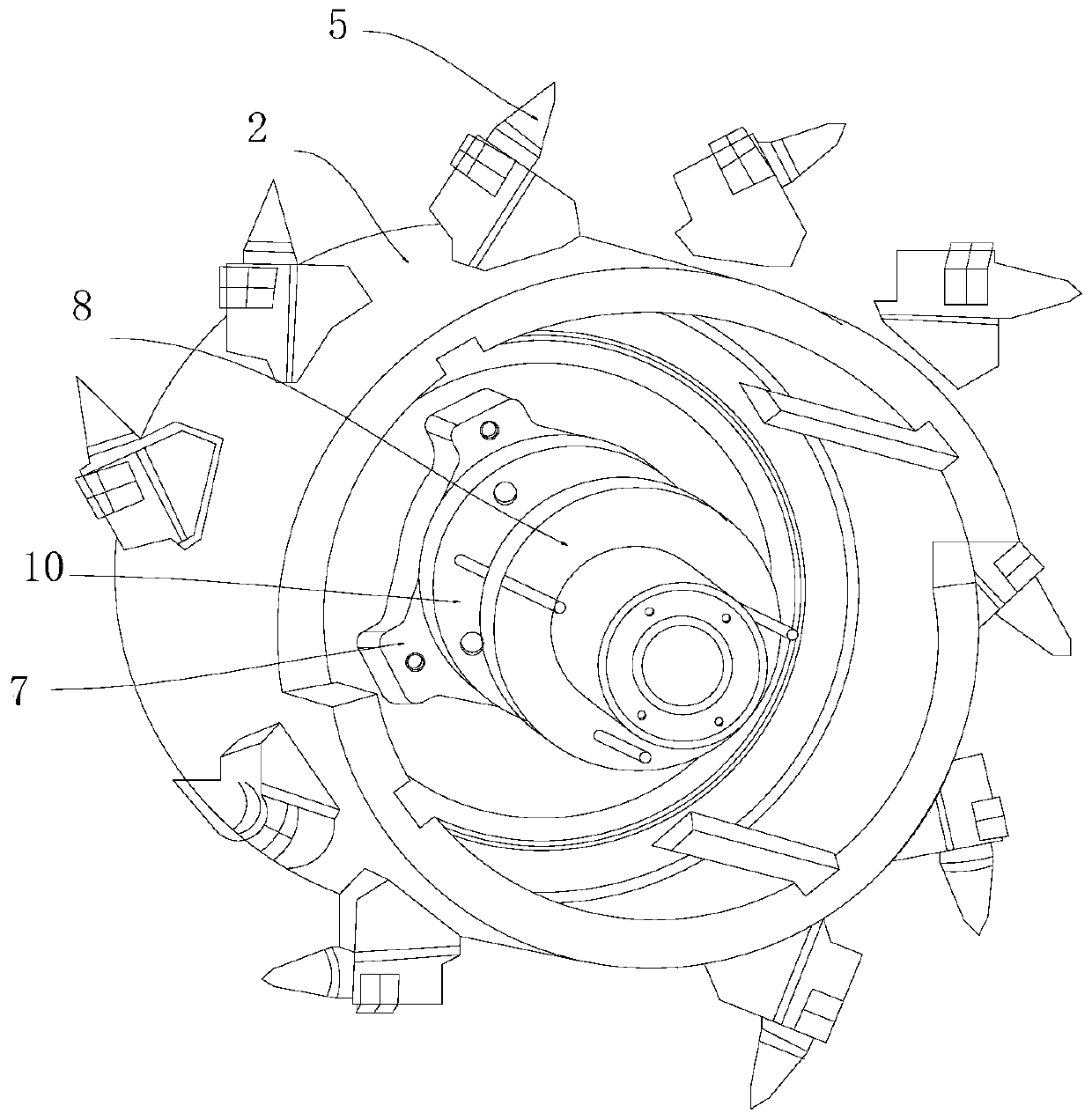

[0029] see Figure 1 to Figure 5 , the present invention includes an inner cutting drum 1 and an outer cutting drum 2 arranged at both ends of the inner cutting drum 1 and connected with the inner cutting drum 1, two groups of outer cutting drums 2 are symmetrical with the inner cutting drum 1 as the center set, and the central axes of the outer cutting drum 2 and the inner cutting drum 1 are arranged on the same straight line, so that the inner cutting drum 1 and the outer cutting drum 2 can maintain a uniform standard rotation pi during the rotary excavation process, and optimize The tunneling effect of the present invention is improved and the tunneling efficiency of the present invention in the tunneling process is improved. At the same time, the outer sides of the inner cutting drum 1 and the outer cutting drum 2 are provided with a plurality of rock-breaking teeth 5, and the rock-breaking teeth 5 are spirally distributed, and the tooth tips of the rock-breaking teeth 5 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com