High-density circulating fluidized bed arc-shaped u-valve return device using b-type particles

A technology of circulating fluidized bed and feeder, applied in the field of circulating fluidized bed, can solve the problems of poor regulation, poor fluidization, flow dead angle of U valve returner, etc., to reduce the risk of coking and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

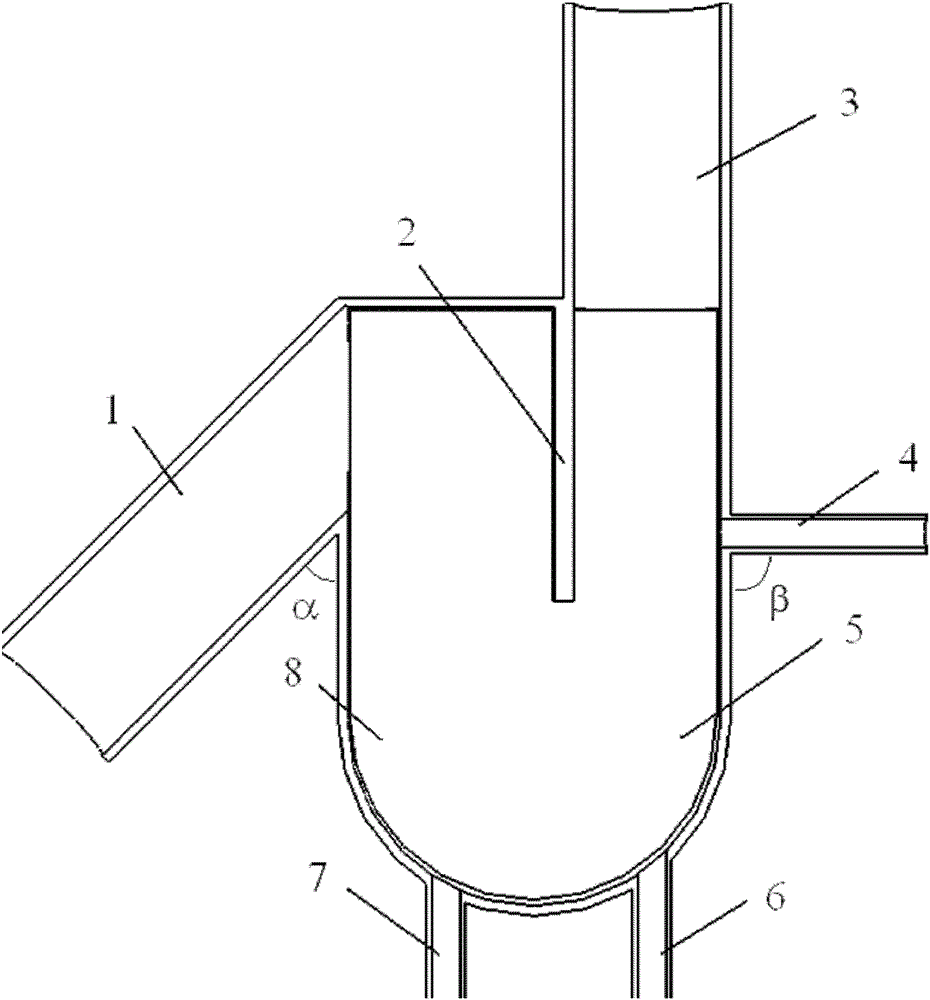

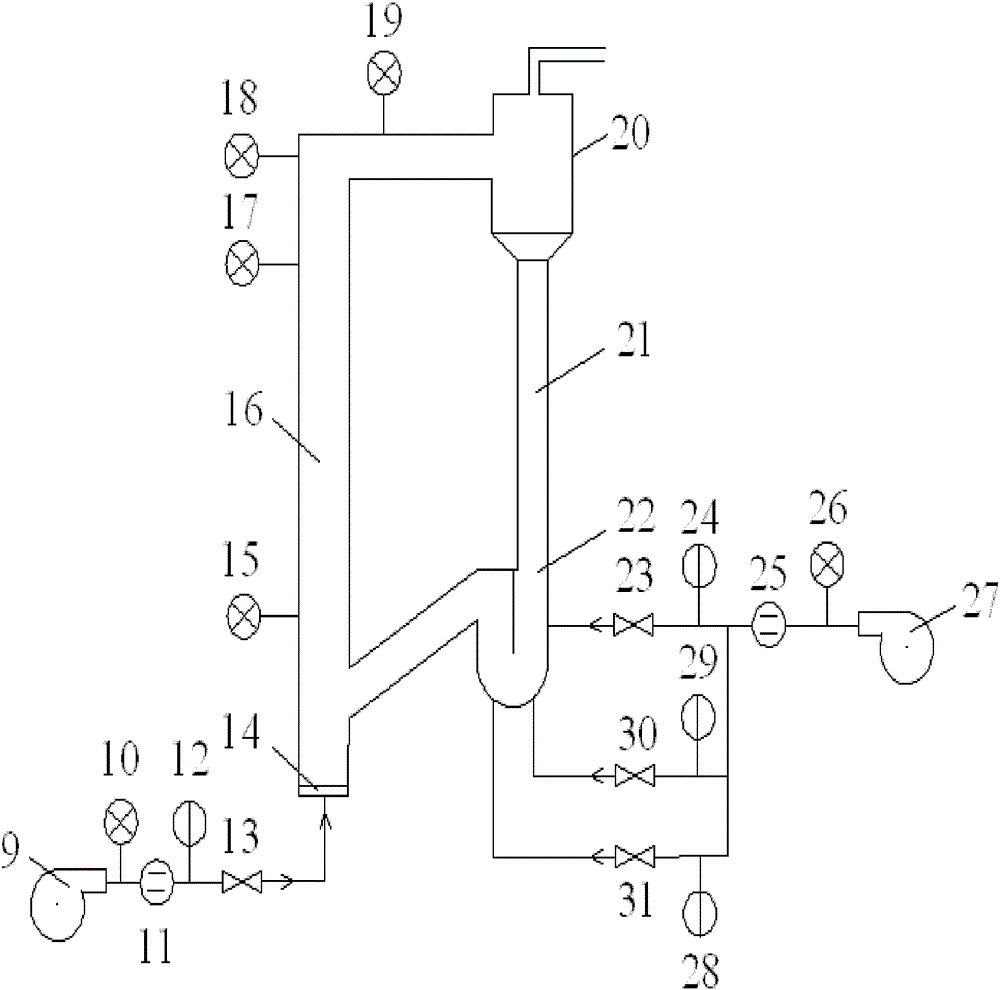

[0022] Such as figure 1 Shown is a schematic structural view of the arc-shaped U-valve feeder 22 of the high-density circulating fluidized bed using Class B particles of the present invention. The adjustment air duct 4, the loose air chamber 5, the loose air duct 6, the return air duct 7, and the return air chamber 8 form. It is characterized in that: 1. The bottom is a U-valve feeder with a circular arc shape. 2. Arrange one return wind and one loose air at the arc-shaped bottom, and arrange one regulating air on the side wall of the loose air chamber. The diameter of the arc-shaped bottom is set to Φc, the diameter of the loose air duct 6 is set to Φs, the diameter of the return air duct 7 is set to Φf, and the diameter of the return duct 3 is set to Φb, the relationship needs to be satisfied: 2Φb<Φc< 3.5Φb, 0.1Φb<Φs, Φf<0.3Φb. The angle between the return feed pipe 1 and the vertical direction is an angle α (30°<α<45°), and the adjustment air pipe 4 of the loose air cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com