Combustible gas energy-saving gasification device for gas appliance

A gasifier and gas technology, which is applied in the field of combustible gas energy-saving gasifiers for burning appliances, can solve the problems of increased use cost, uncontrollable fire volume, insufficient combustion, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

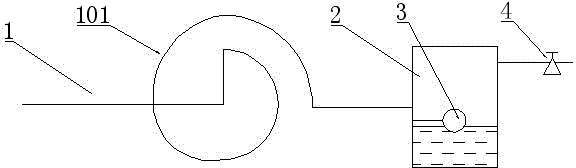

[0024] like figure 1 As shown, the combustible gas energy-saving gasifier for burning appliances involved in the present invention has a liquefied gas conduit 1, and a gas-liquid separation tank 2 is connected to the outlet of the liquefied gas conduit 1. The first liquid level controller 3 of the gas switch (the first liquid level controller 3 can also be used to signal the electric control valve installed at the inlet of the liquefied gas conduit 1, and the electric control valve controls the liquefied gas switch). The inlet of the liquefied gas conduit 1 and the outlet of the gas-liquid separation tank 2 are respectively a liquid phase inlet and a gas phase outlet, and a pressure regulating valve 4 is provided on the gas phase outlet pipeline to adapt to cookers of different specifications.

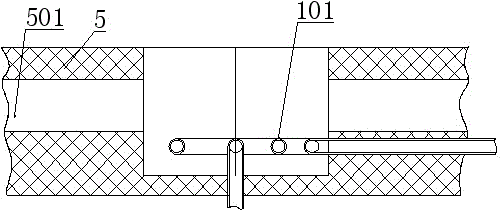

[0025] like figure 2 As shown, the main body of the liquefied gas conduit 1 is a waste heat heating gasification coil 101, and the waste heat heating gasification coil 101 is arrange...

Embodiment 2

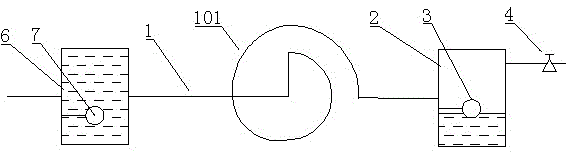

[0027] like image 3 As shown, the combustible gas energy-saving vaporizer for burning appliances involved in the present invention has a liquefied gas conduit 1, and a gas-liquid separation tank 2 is connected to the outlet of the liquefied gas conduit 1, and the inlet of the liquefied gas conduit 1 and the outlet of the gas-liquid separation tank 2 are respectively A liquid phase inlet and a gas phase outlet, the gas phase outlet pipeline is provided with a pressure regulating valve 4 to adapt to cookers of different specifications. The gas-liquid separation tank 2 is provided with a first liquid level controller 3, the inlet of the liquefied gas conduit 1 is provided with a liquid storage tank 6, and the liquid storage tank 6 is provided with a second liquid level controller 7. A liquid level controller 3 is a high liquid level controller, and the second liquid level controller 7 is a low liquid level controller. The high liquid level controller prevents liquid from enterin...

Embodiment 3

[0030] like Figure 4 As shown, the combustible gas energy-saving vaporizer for burning appliances involved in the present invention has a liquefied gas conduit 1, and a gas-liquid separation tank 2 is connected to the outlet of the liquefied gas conduit 1, and the inlet of the liquefied gas conduit 1 and the outlet of the gas-liquid separation tank 2 are respectively A liquid phase inlet and a gas phase outlet, the gas phase outlet pipeline is provided with a pressure regulating valve 4 to adapt to cookers of different specifications.

[0031] The gas-liquid separation tank 2 is provided with a first liquid level controller 3, the inlet of the liquefied gas conduit 1 is provided with a liquid storage tank 6, and the liquid storage tank 6 is provided with a second liquid level controller 7. A liquid level controller 3 is a high liquid level controller, and the second liquid level controller 7 is a low liquid level controller. The high liquid level controller prevents liquid fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com