Internal circulation type solid particle air heat absorber for solar thermal power generation

A solar thermal power generation, solid particle technology, applied in solar thermal power generation, solar collectors, solar thermal energy and other directions, can solve the problems of thermal stress damage of heat sink materials, high solar concentration energy flow density, poor flow stability, etc. , to achieve the effect of efficient absorption, high radiation absorption rate, and avoid overheating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

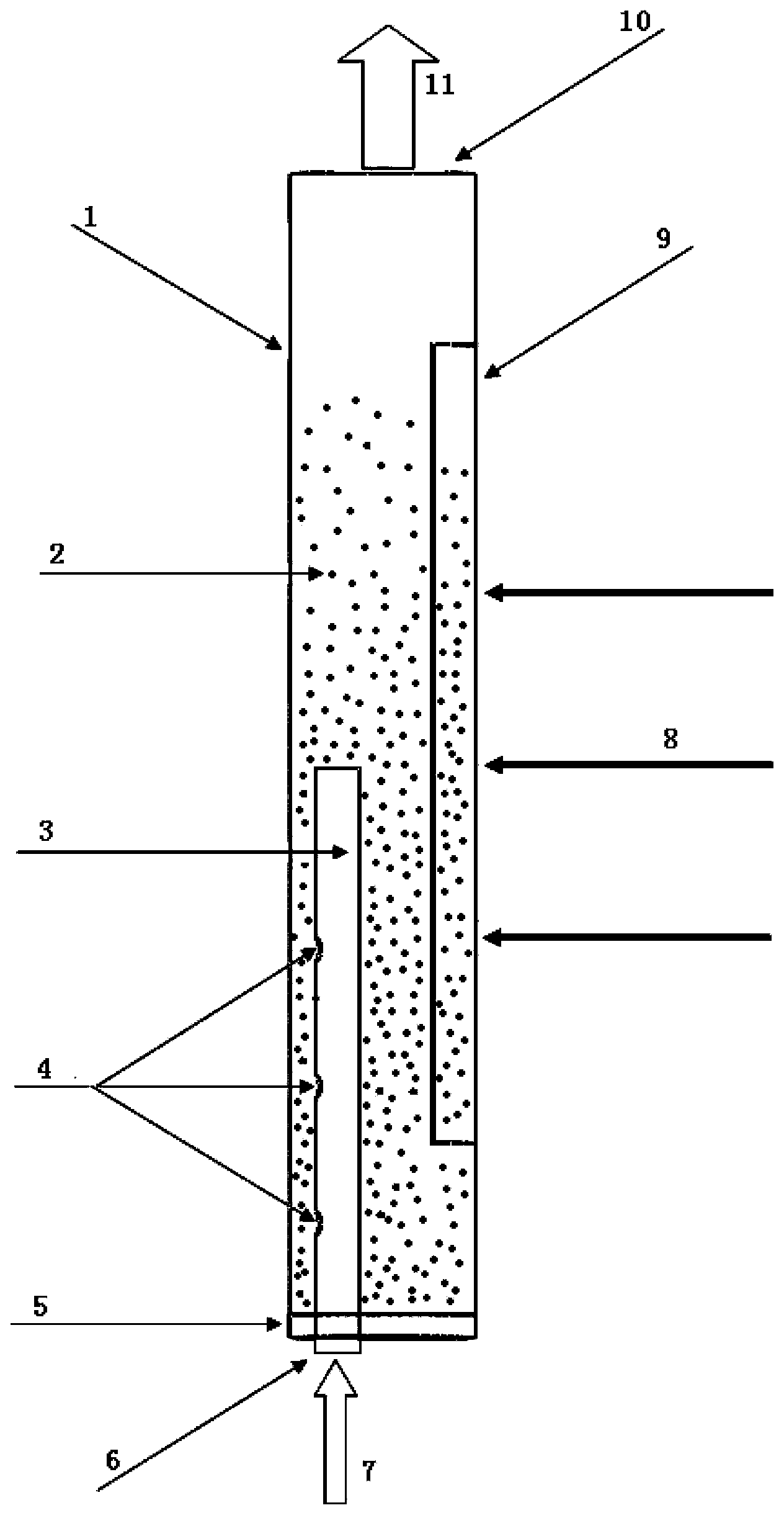

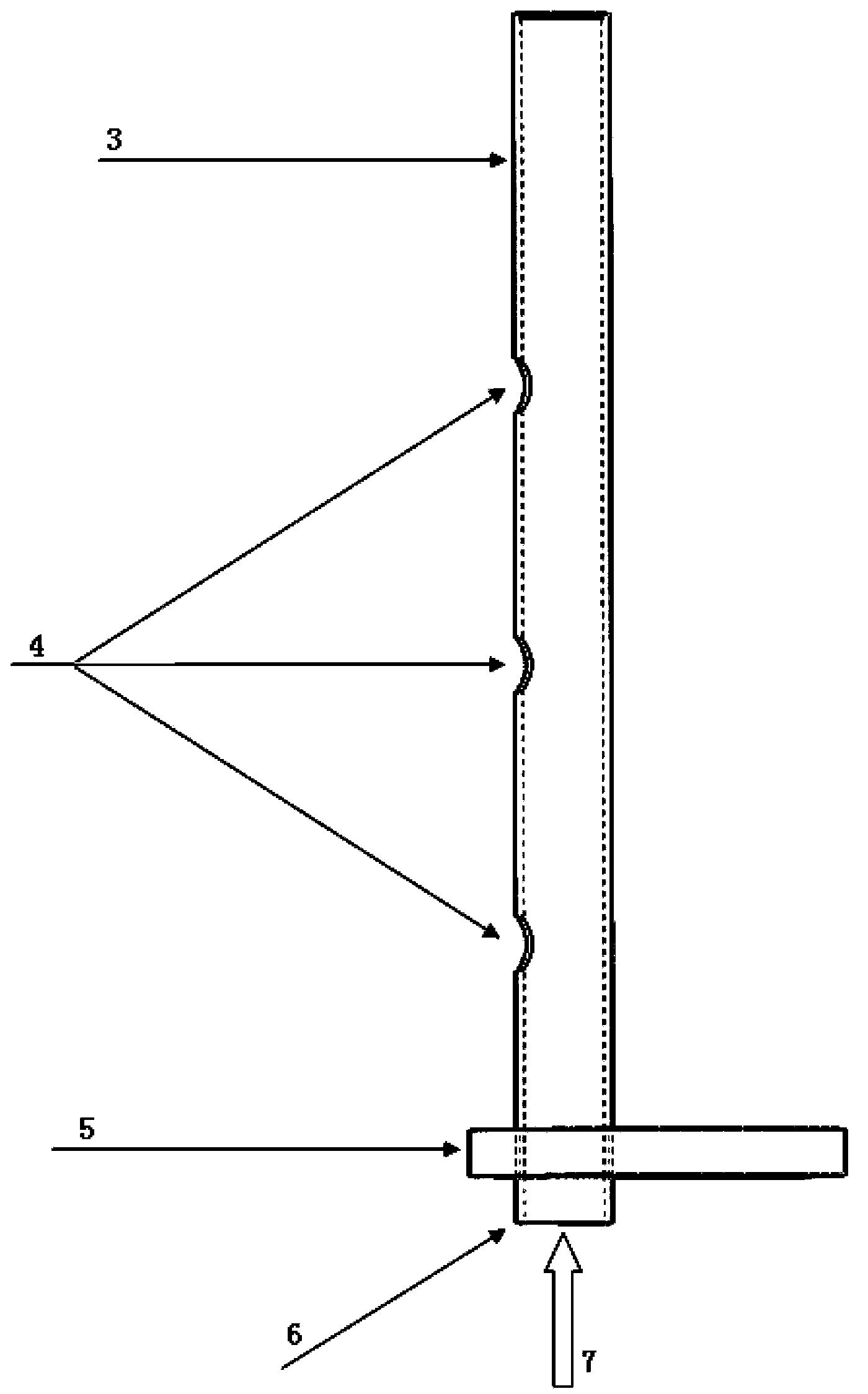

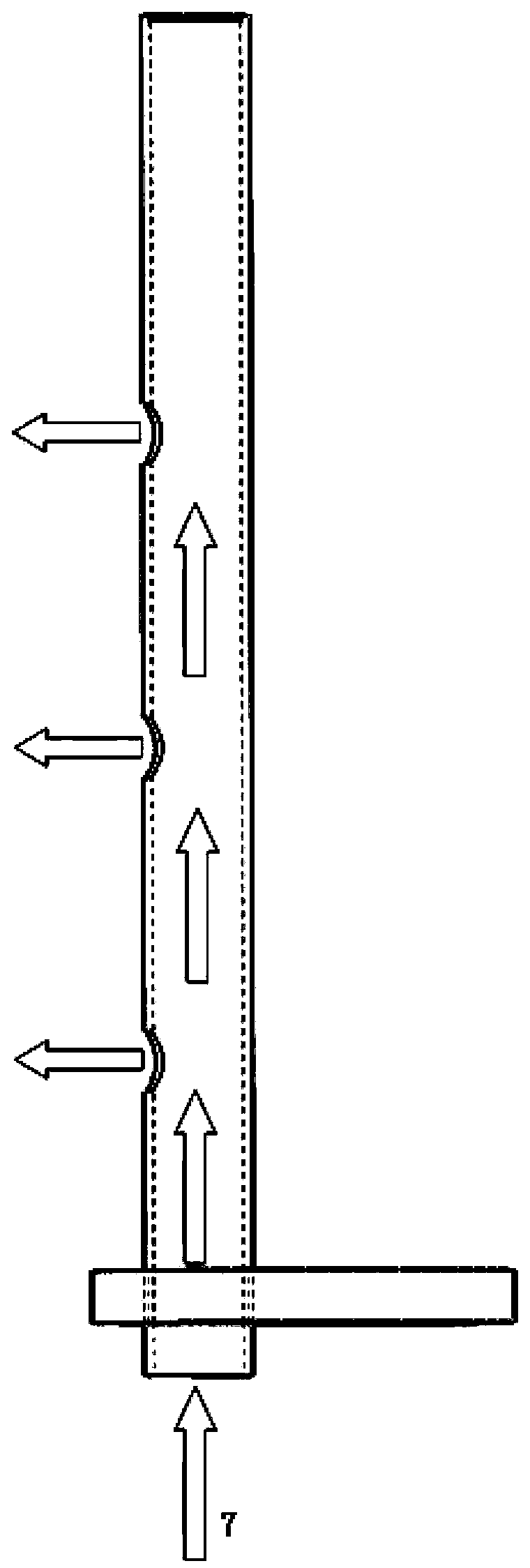

[0016] figure 1 Shown is the internal circulation solid particle air heat absorber of the present invention. The heat absorber is composed of a heat absorber cavity 1 , solid particles 2 , an air inlet duct 3 , an air inlet 6 , a light-transmitting window 9 , and an air outlet 10 . The heat absorber cavity 1 is cylindrical or square and made of high temperature resistant material. The base 5 is a part of the heat absorber cavity 1, is located at the bottom of the heat absorber cavity 1, is sealed and connected with the heat absorber cavity 1, and is made of high temperature resistant material. The intake duct 3 is fixed in the cavity 1 of the heat absorber. One end of the air intake duct 3 is sealed, and the other end is used as an air inlet 6 . The light-transmitting window 9 is a part of the heat absorber cavity 1 and is located on the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com