Accurate circuit board element location and detection method based on image feature

A precise positioning, circuit board technology, applied in measurement devices, optical testing flaws/defects, instruments, etc., can solve problems such as difficulty in detecting artificial electronic components, and achieve the effect of realizing industrial production automation, stable matching results, and high detection quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

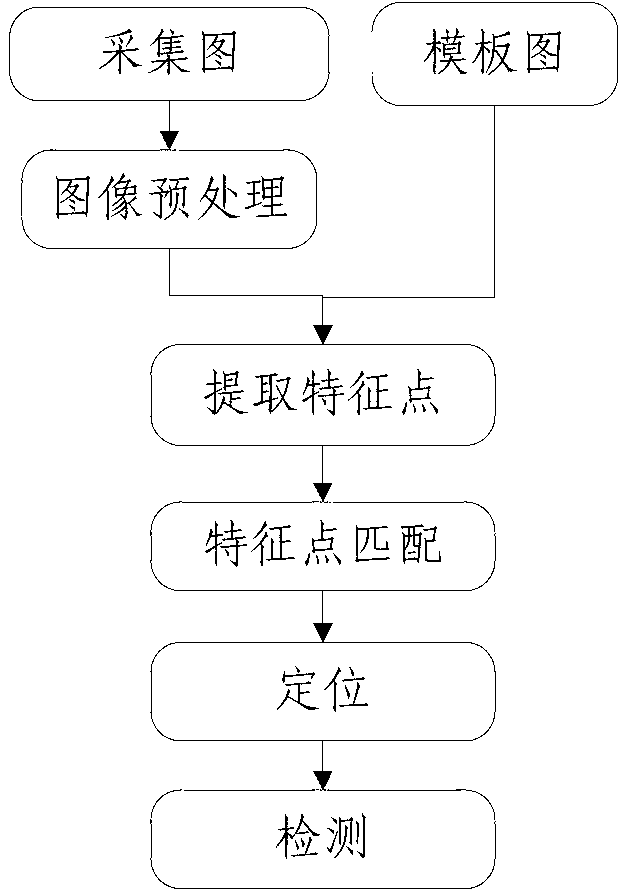

[0017] In the application of circuit board component positioning and detection, the picture of the circuit board to be tested is collected first, and the characteristic point pairs of the collected picture and the standard circuit board component template picture are obtained through the SURF algorithm. In general, SURF-based image matching does not require image preprocessing. In special cases, it is subject to external environment interference (such as underwater), and some preprocessing of the image (image enhancement, filtering, smoothing) is required. etc.). The Accelerated Robust Feature (SURF) algorithm was proposed by Bay et al. in 2006. It is an algorithm with invariance to image perspective, scale, rotation and illumination changes. It is aimed at the SIFT proposed by Lowe et al. Algorithm improvements. Image matching based on SURF algorithm is mainly divided into three steps: feature point extraction, feature point description and feature point matching. Bay et al....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com