Neglected loading detection mechanism for parts

A detection mechanism and component technology, which is applied in the field of component missing detection mechanism, can solve the problems of high use and maintenance costs, inability to install, and low accuracy, and achieves reduced use and maintenance costs, small footprint, and low manufacturing costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

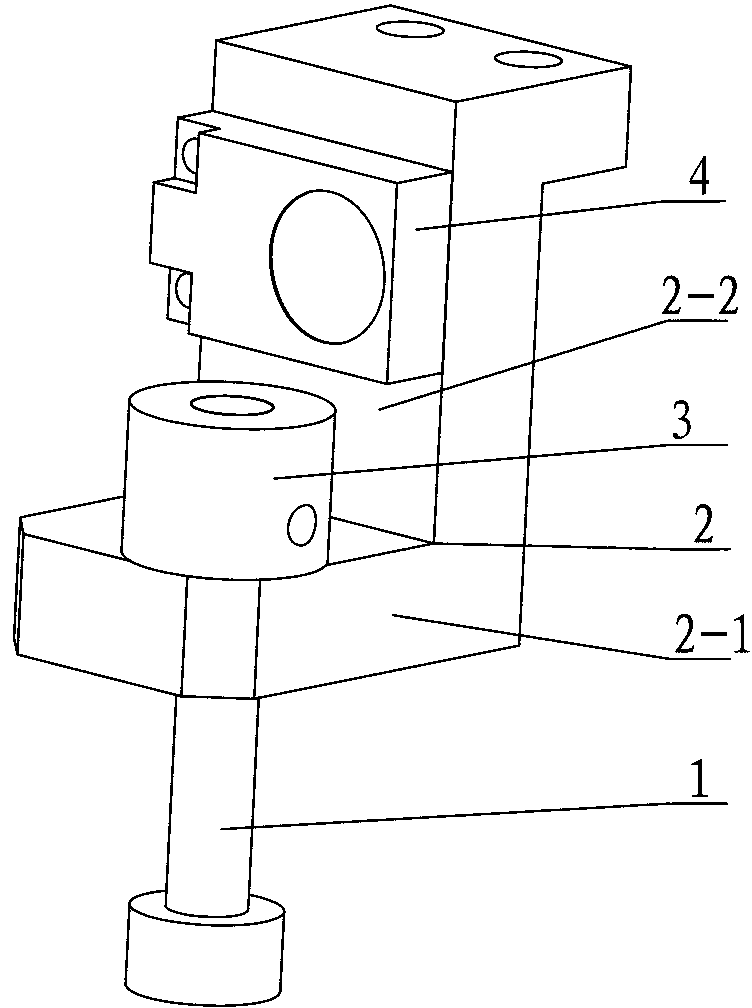

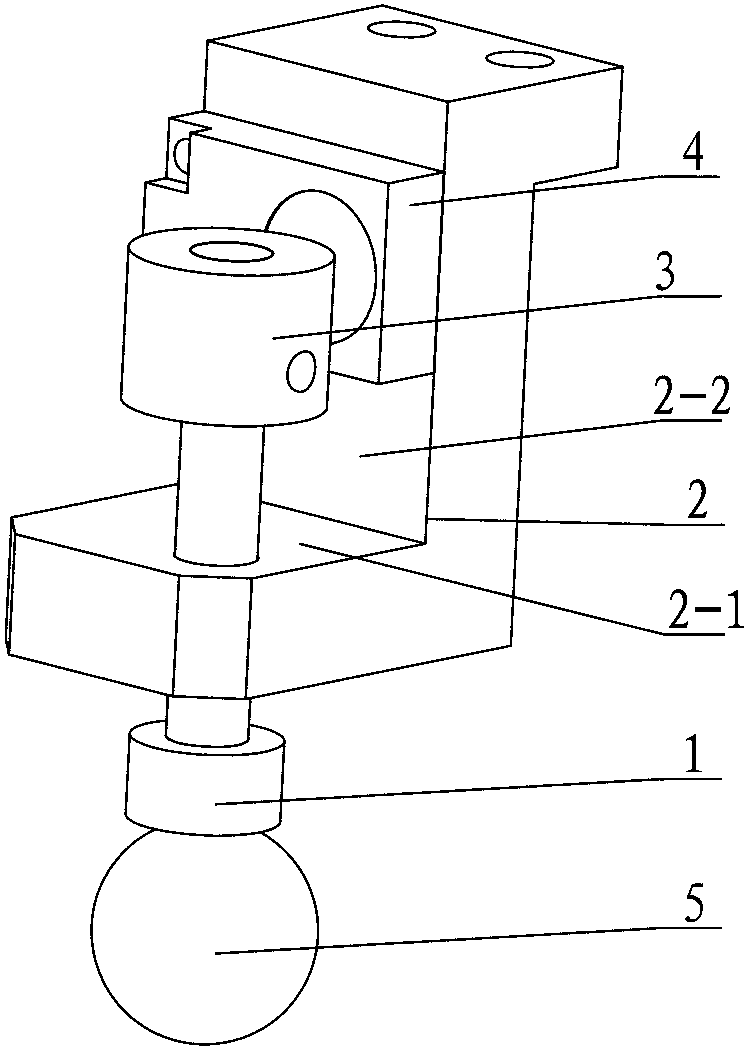

[0010] See figure 1 , 2 As shown, the component missing detection mechanism of the present invention includes a bracket seat 2 , a push rod 1 and a proximity switch 4 . See figure 1 , 2 , the bracket base 2 of the present invention includes a bottom plate 2-1 and a riser 2-2, the top of the riser 2-2 is provided with a mounting hole, the bracket base 2 can be connected with the movable part, and the bracket base 2 is driven along the Moving in the vertical direction makes the component missing detection mechanism of the present invention move as a whole.

[0011] See figure 1 As shown, the push rod 1 of the present invention is placed vertically through the installation hole of the base plate 2-1 and can move freely along the vertical direction. The proximity switch 4 is installed on the vertical plate 2-2 of the bracket seat 2. The upper magnetic part 3 is opposite to the proximity switch 4 in the detection area. The outer peripheral dimension of the magnetic part 3 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com