Automatic selection method of dynamic scheduling strategy of semiconductor production line

A dynamic scheduling and scheduling strategy technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems that performance indicators cannot be optimized, real-time and production performance are difficult to balance, and computing time is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

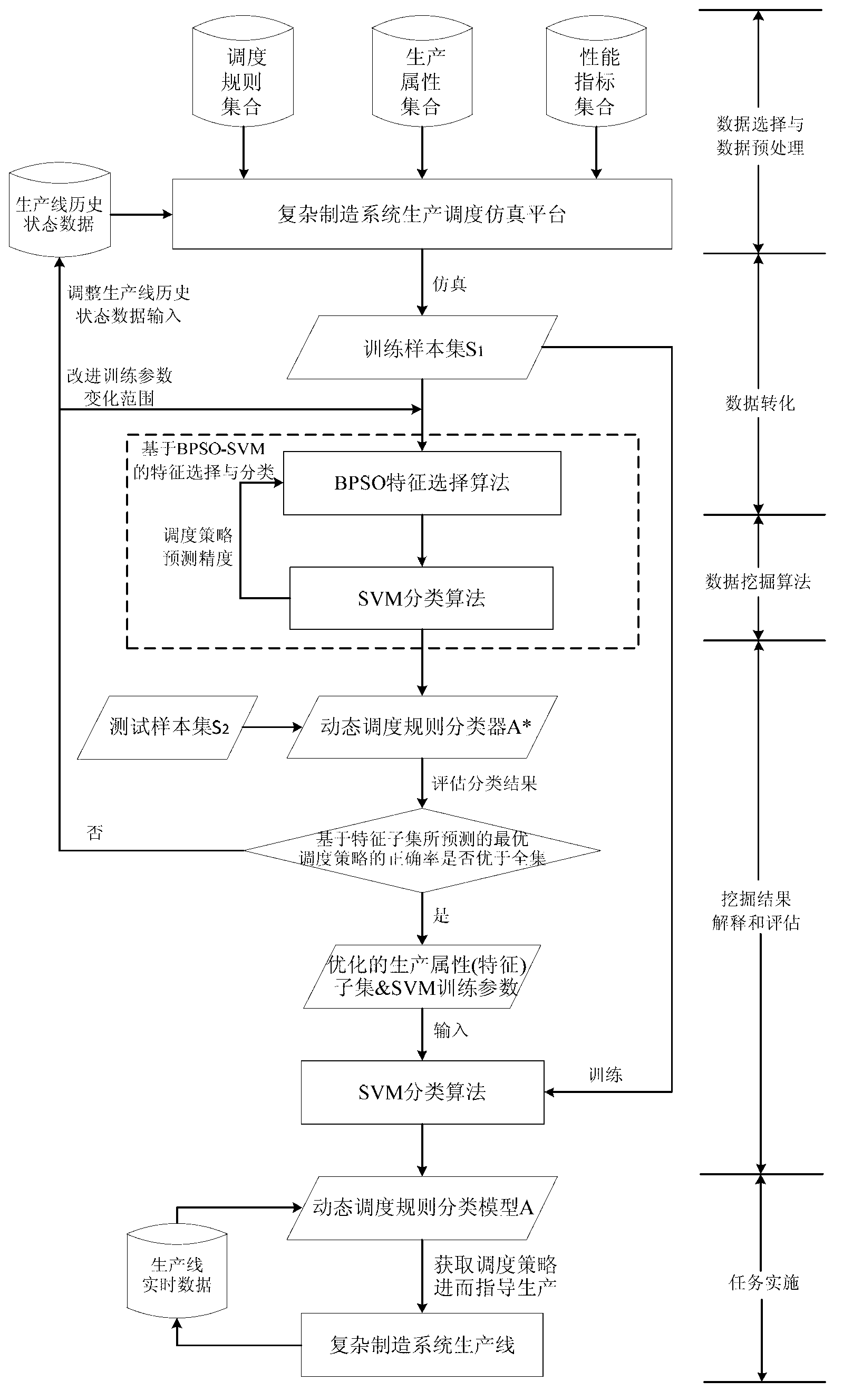

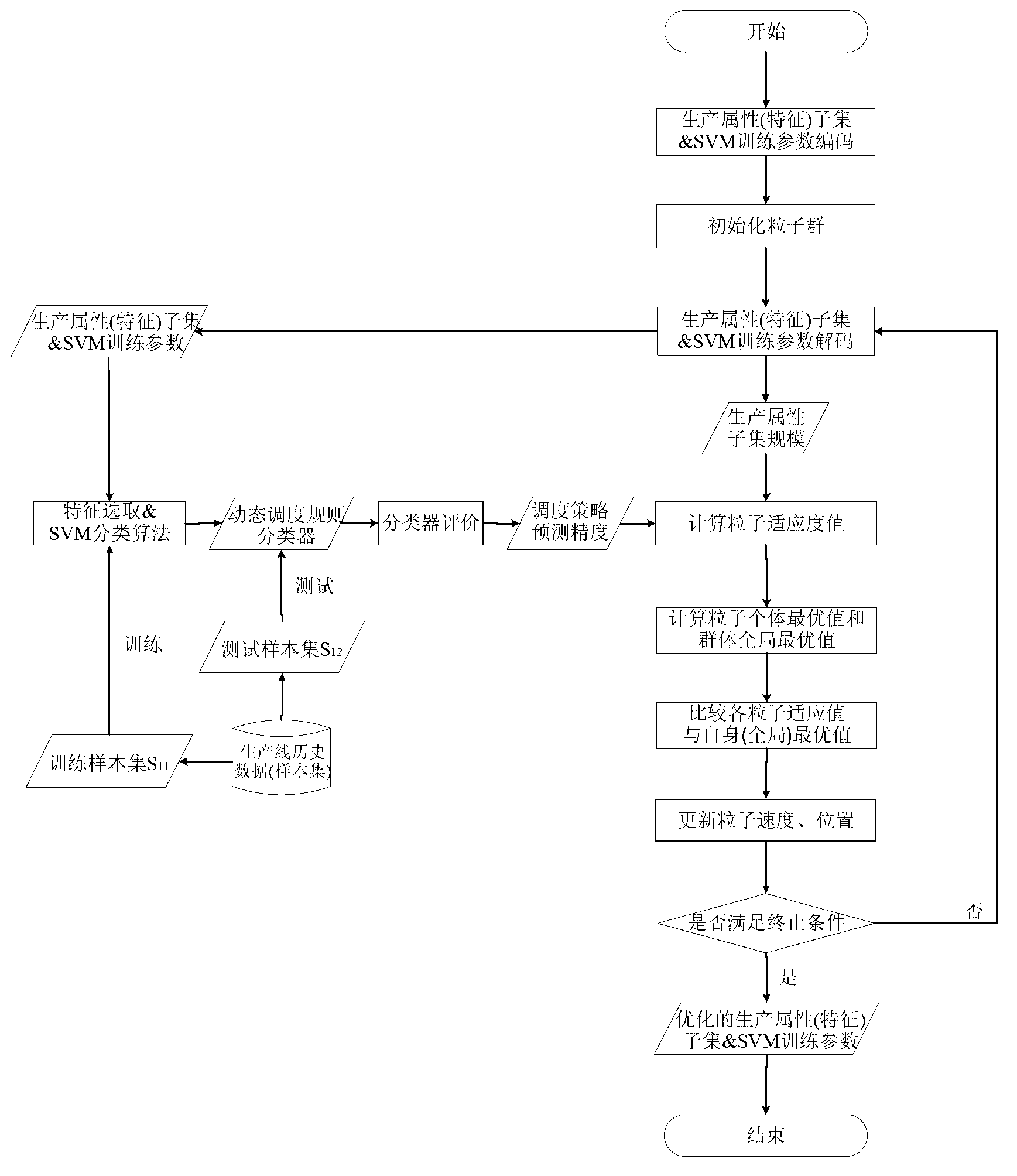

[0050] Such as figure 1 As shown, a method for automatically selecting a dynamic scheduling strategy for a semiconductor production line includes the following steps:

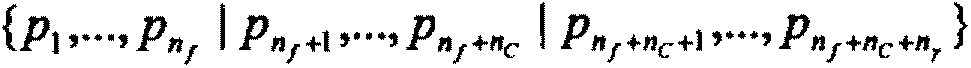

[0051] 1) Obtain a production line production attribute set, a scheduling policy set, and a performance index set according to an actual semiconductor production line, wherein the production line production property set includes production line attributes and processing area attributes; the scheduling policy set includes delivery-based scheduling policies, Scheduling strategy based on processing cycle, scheduling stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com