+/-1100kV high-voltage direct current disconnecting switch

A technology of isolating switch and high-voltage direct current, which is applied in the direction of the switch that is not connected to the bridge contact point, can solve the problem that the high-voltage direct current isolating switch has not been produced, and achieve the effect of saving raw materials, saving space, and rotating smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

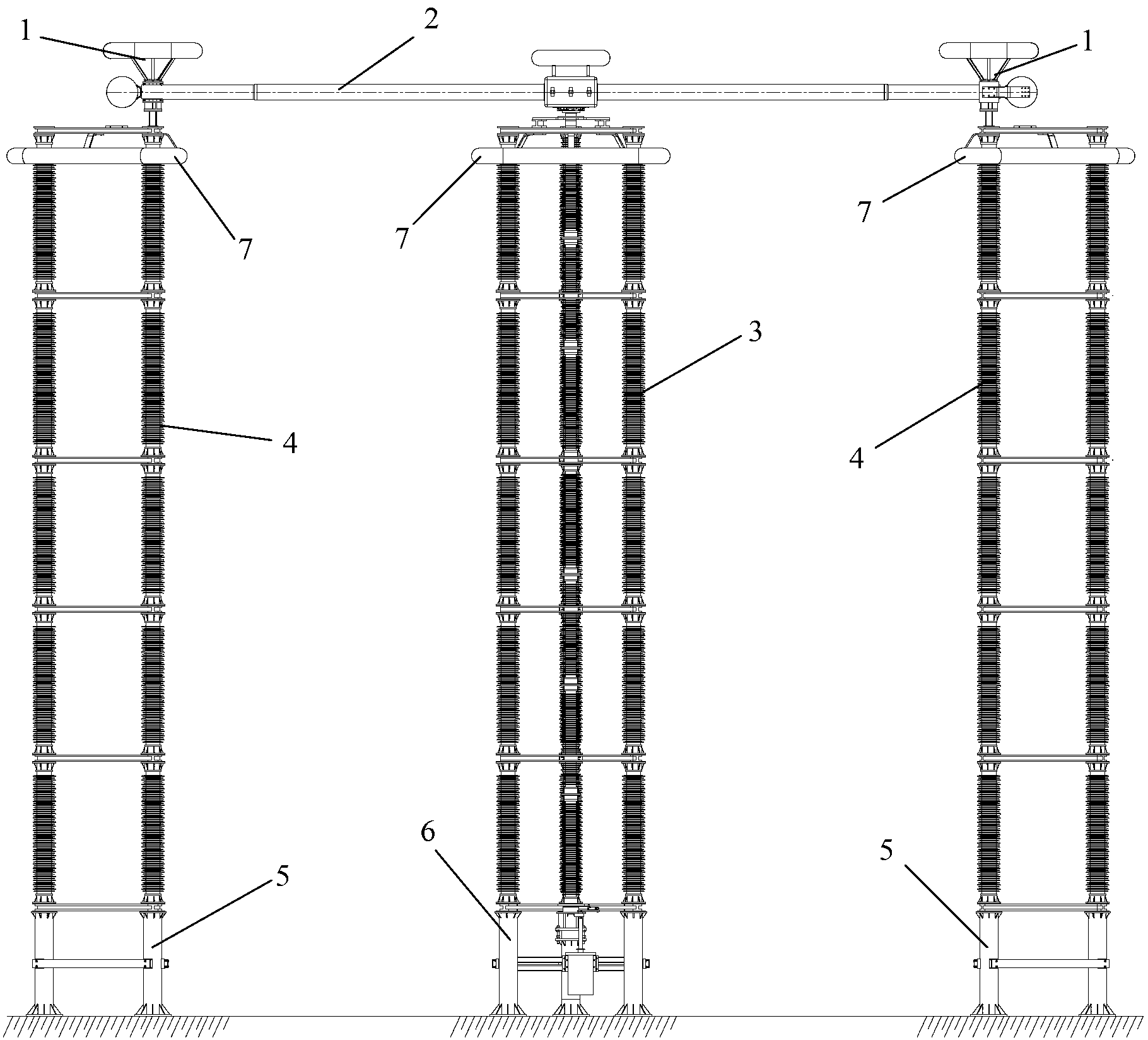

[0037] The present invention is described in further detail below in conjunction with accompanying drawing:

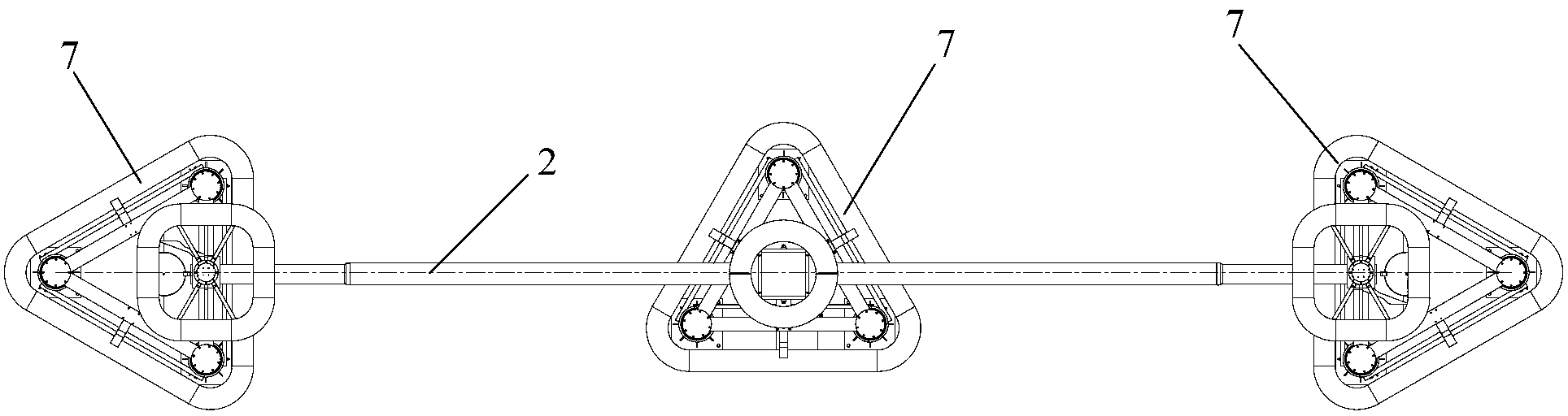

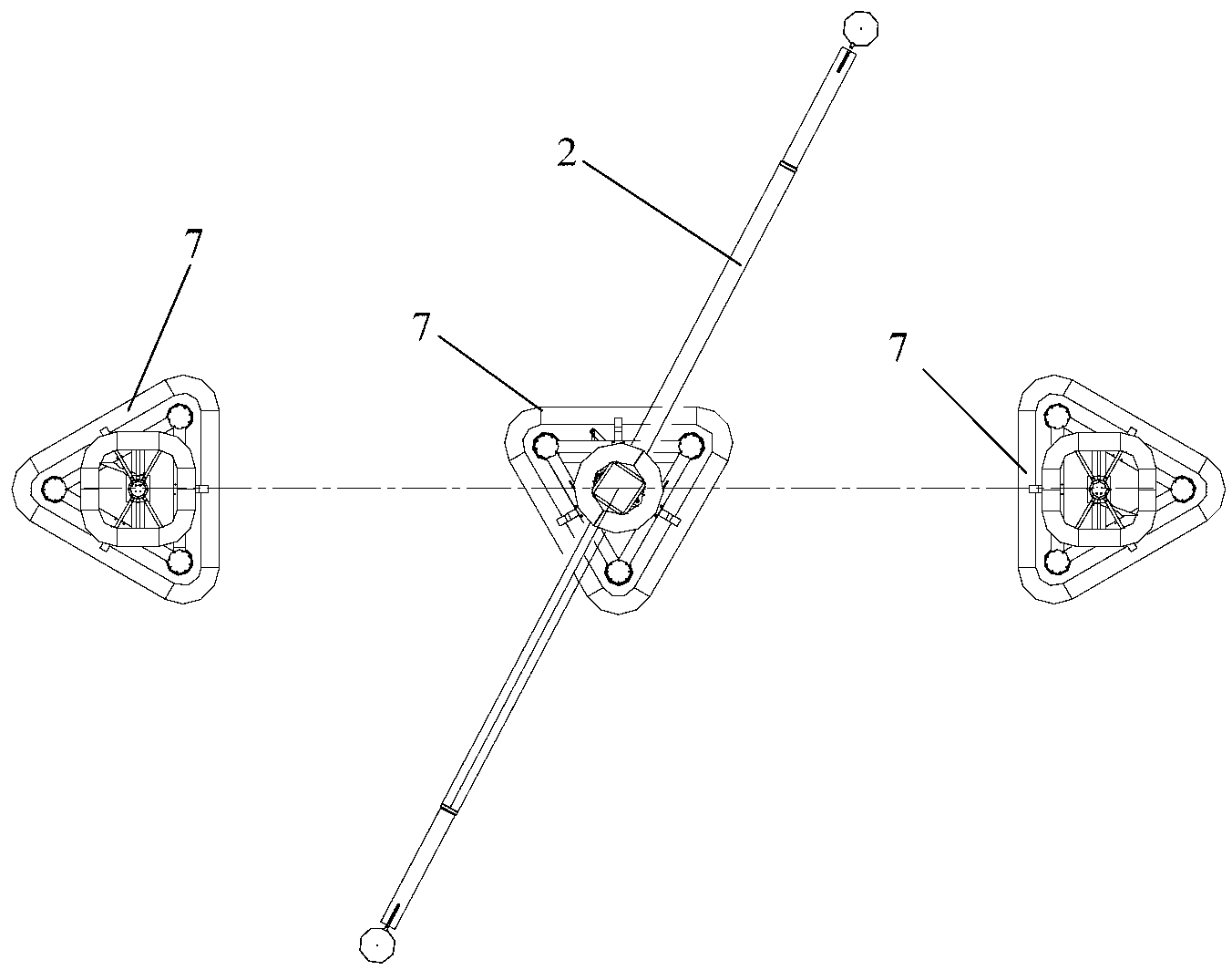

[0038] join figure 1 , the present invention includes two static side post insulators 4 with static contacts 1 on the top, and an intermediate post insulator 3 arranged between the two static side post insulators; as Figure 5-1 and 5-2 As shown, the two static side post insulators 4 and the middle post insulator 3 are combined post insulators, wherein each combined post insulator consists of three separate post insulators 41 distributed at the three vertices of the triangle and several triangle connection frames 42 are assembled into one body, and the top of the post insulator 41 is provided with a triangular insulator grading ring 7, such as Figure 6-1 and 6-2 As shown, each side of the insulator grading ring 7 is welded with a grading ring mounting plate 71 fixedly connected to the triangular connection frame 42 on the top of the post insulator 4 . like Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com