Polymeric compositions with voltage stabilizer additive

A composition and polymer technology, applied in the direction of circuits, insulated cables, electrical components, etc., can solve problems such as poor compatibility of voltage stabilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

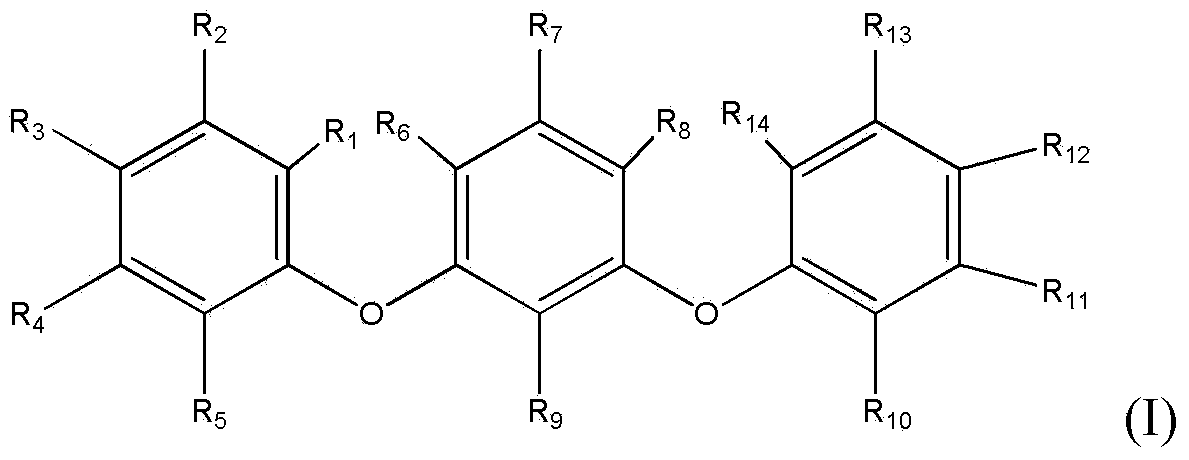

[0090] Example 1 is an LDPE containing 2.9 wt% diphenoxybenzene (mole content equivalent to 2 wt% anthracene), obtained from Sigma Aldrich, made with a mixing temperature of 140°C.

Embodiment 2

[0091] Example 2 is an LDPE containing 2.2 wt% N-benzanilide (mole content equivalent to 2 wt% anthracene), obtained from Sigma Aldrich, made with a mixing temperature of 190°C.

[0092] Comparative sample A is an LDPE compounded at a temperature of 140°C without a voltage stabilizer.

[0093] Comparative Sample B is LDPE compounded at 225°C without voltage stabilizer.

[0094] Comparative Sample C is an LDPE containing 2 wt% anthracene, mixed at a temperature of 225°C.

[0095] Comparative Sample A

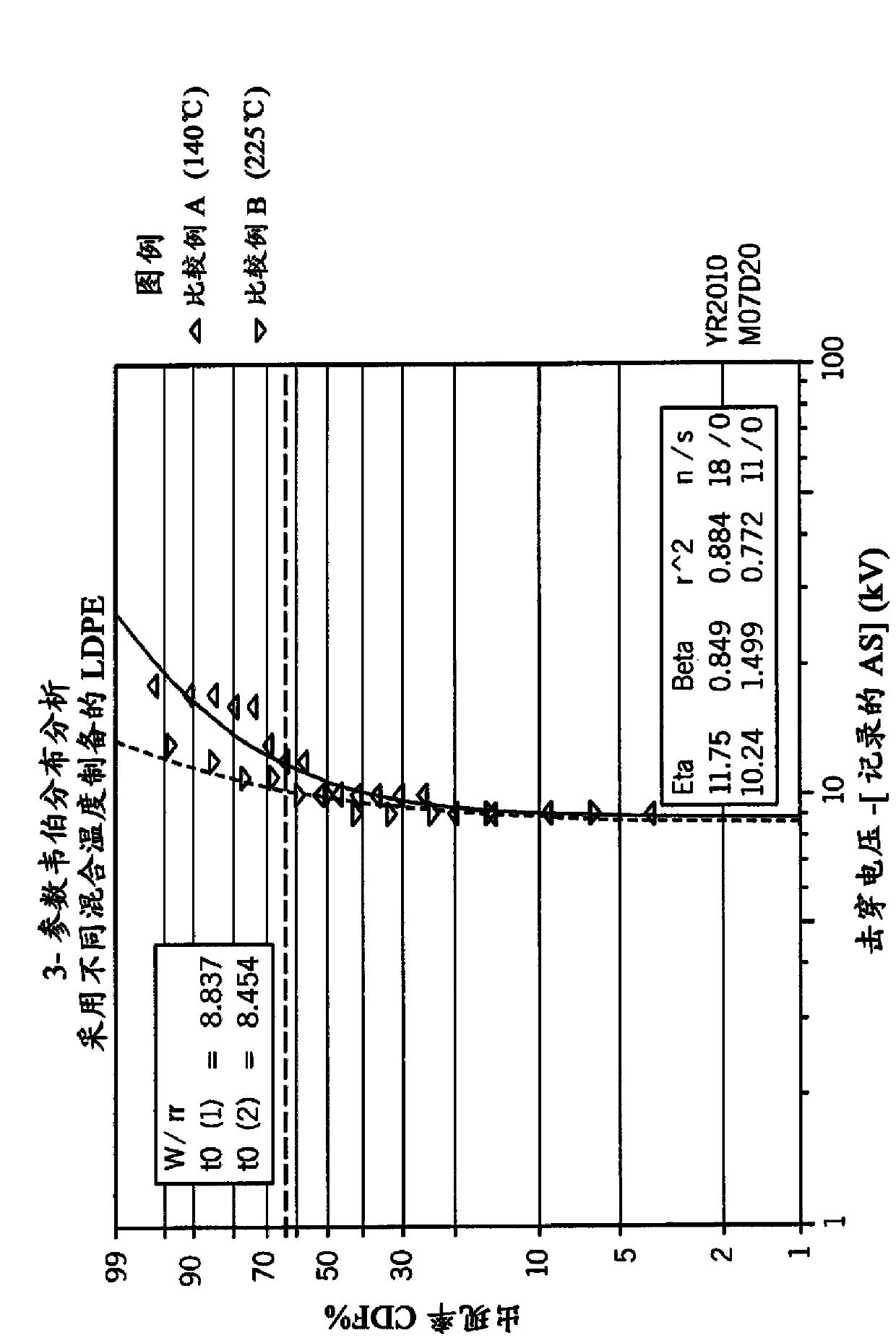

[0096] A series of 18 specimens for Comparative Sample A was fitted to a 2-parameter Weibull failure distribution. The data exhibited significant nonlinearity, resulting in poor correlation (r^2 of 0.75). Using offset t0=8.8kV, it is found that the 3-parameter Weber failure distribution is more suitable for describing the failure distribution (r^2 is 0.88) where offset (offset) t0=8.8kV. as in figure 2 As shown in , using a 90% confidence interval spanning 10.7 to 13.7 kV, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com