Method for automatic hydraulic compensation in fluid-onducting systems

An automatic and hydraulic technology, applied in the direction of mechanical equipment, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of ignorance of pipe guidance control, insufficient pipeline regulating valves, and impossible static adjustment, etc., to reduce energy consumption , small pressure loss, and the effect of reducing flow noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

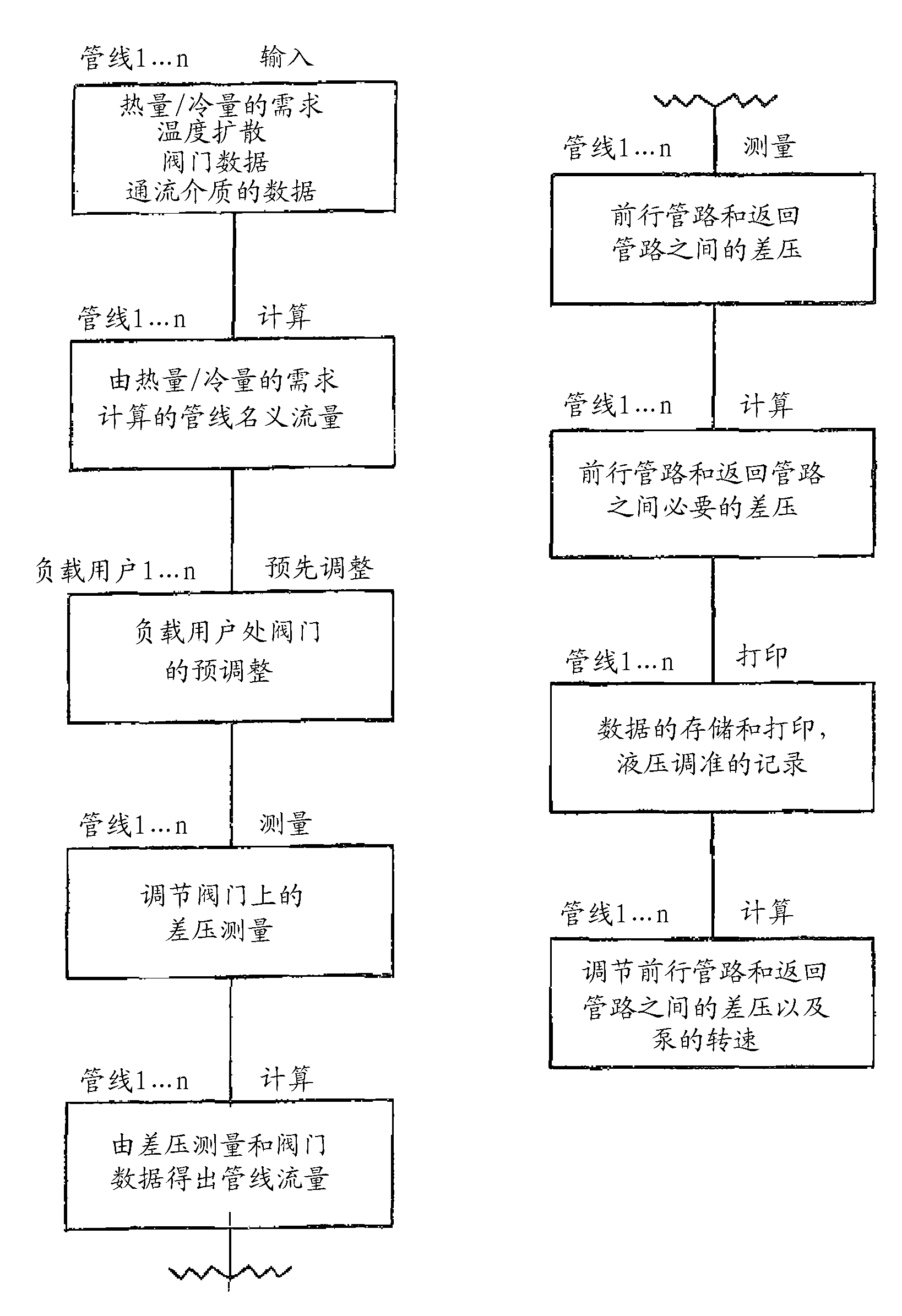

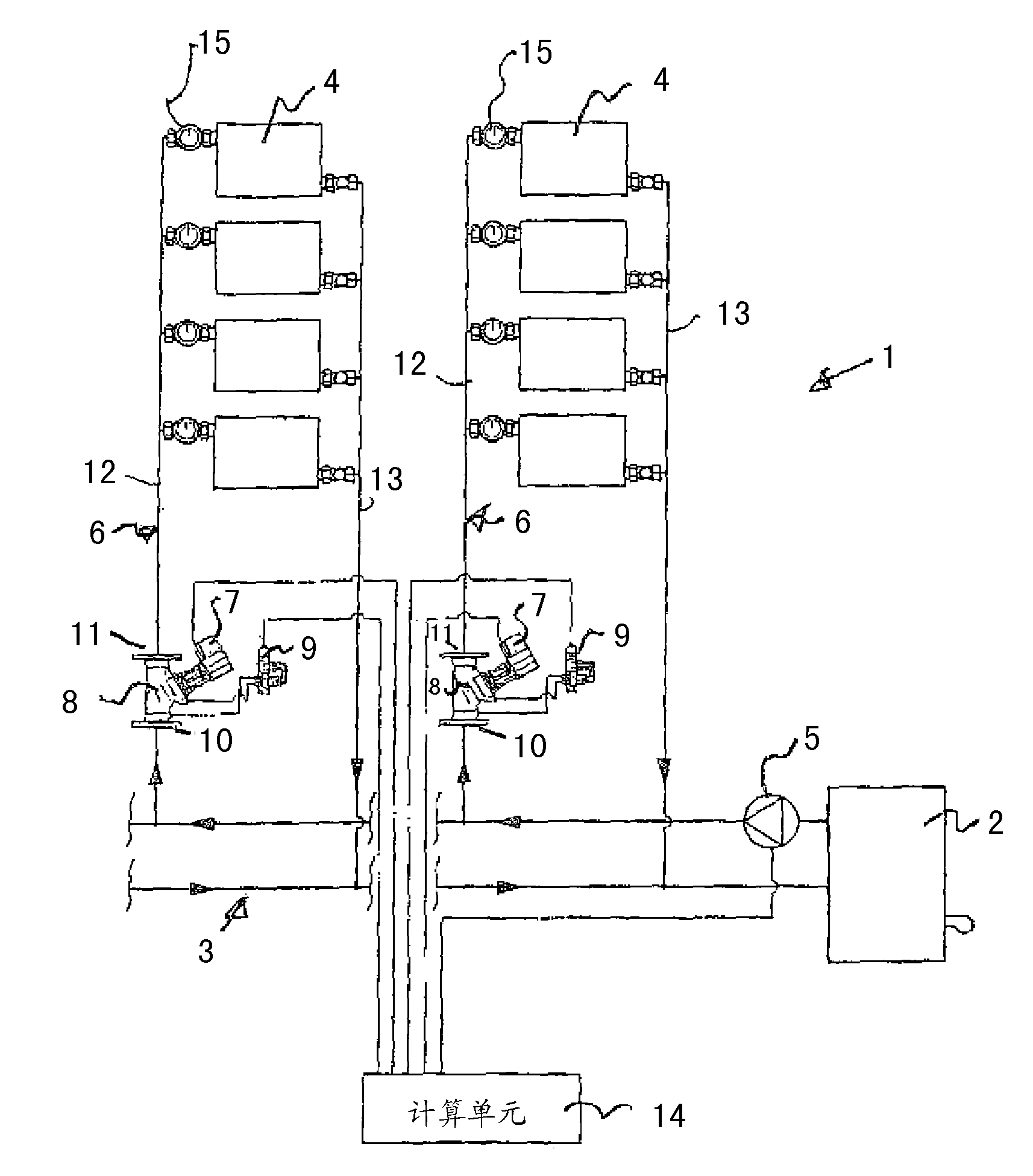

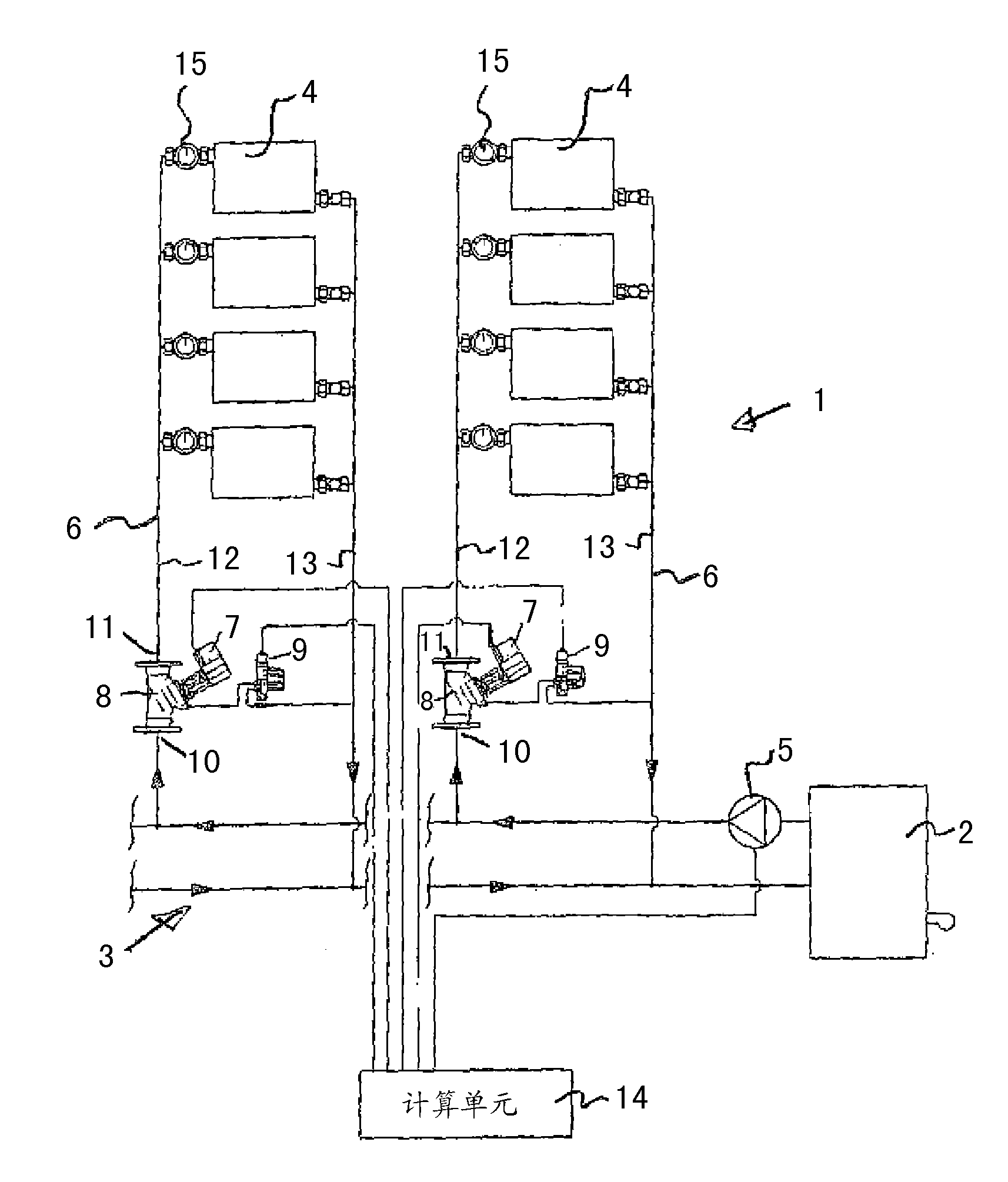

[0021] As shown in FIG. 3 , in the method according to the invention the plant parameters are first entered, read into a computing unit and stored therein.

[0022] For each line 1 to n, for example, heat / cooling requirements, temperature spread, valve data and parameters of the flow medium are entered. Then for each line 1 to n, the calculation of the nominal flow of the line is performed from the calculation of the heating / cooling demand. In addition, a presetting is carried out for each load subscriber 1 to n, that is to say the valves on the respective load subscriber are preadjusted. In addition for each line 1 to n a differential pressure measurement is carried out at the regulating valve. Calculations of line flow are then made from differential pressure measurements and valve data. These data are read and stored in the computing unit. In the case of a truly permanent dynamic hydraulic adjustment of the plant, a measurement of the line differential pressure between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com