Method for estimating content of sulfur oxide at inlet of desulfurization system based on as-fired coal quality measurement

A technology of sulfur oxides and desulfurization system, which is applied in prediction, measurement device, design optimization/simulation, etc., can solve the problems of delayed time lag of coal quality analysis report, prolonged prediction time, affecting desulfurization efficiency, etc., and achieve excellent desulfurization efficiency , small pump power consumption, avoid the effect of inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

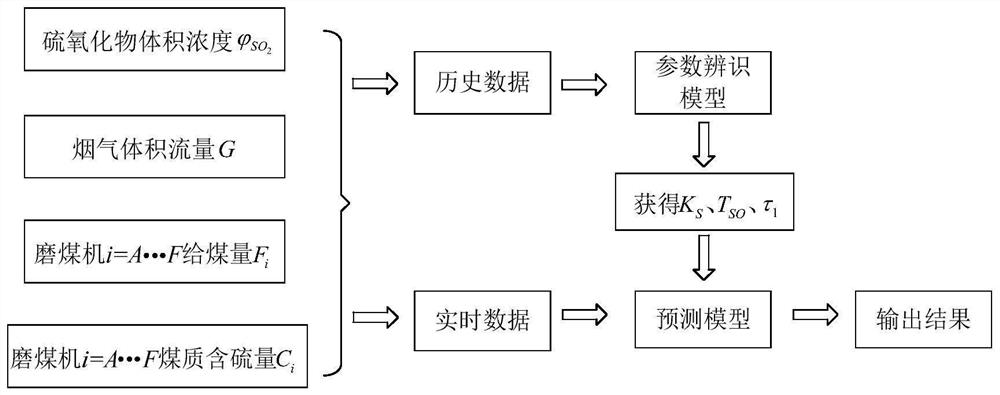

[0041] Such as figure 1 As shown, a method for predicting the content of sulfur oxides at the inlet of the desulfurization system based on the measurement of the incoming coal quality includes the following steps:

[0042] Step 1: Record historical data of key parameters;

[0043] First, measure and record flue gas volume flow G and volume concentration of sulfur oxides at the inlet of the desulfurization system through the furnace coal quality measuring device and the sensors installed in the power plant Sulfur content of each pulverizer coal quality C i and coal feed F of coal mill i i historical data.

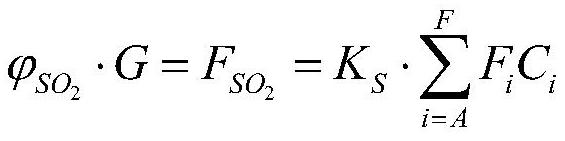

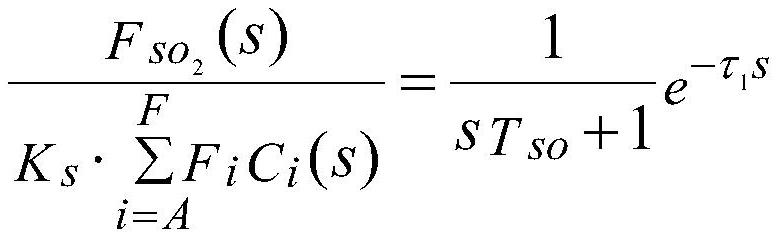

[0044] Step 2: Construct the steady-state conservation equation of sulfur content;

[0045] The sulfur content information of the coal quality of the pulverizer is obtained through the coal quality measuring device. The sulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com