Multifunctional green fence pruning manipulator capable of reconfiguring rapidly

The utility model relates to a hedge trimming tool and a multi-functional technology, which is applied in the field of a multi-functional hedge trimming manipulator that can be quickly reconfigured. , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

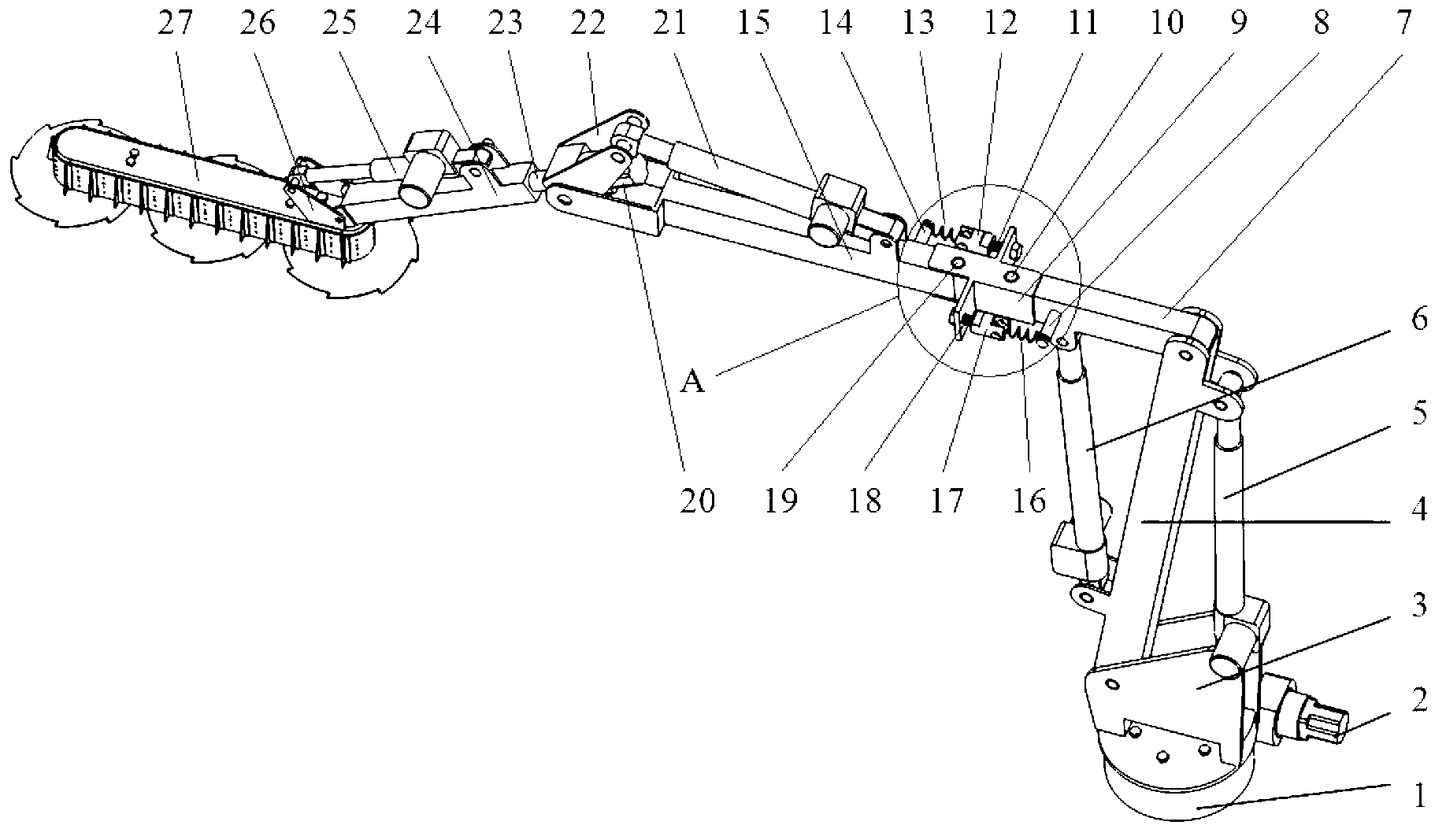

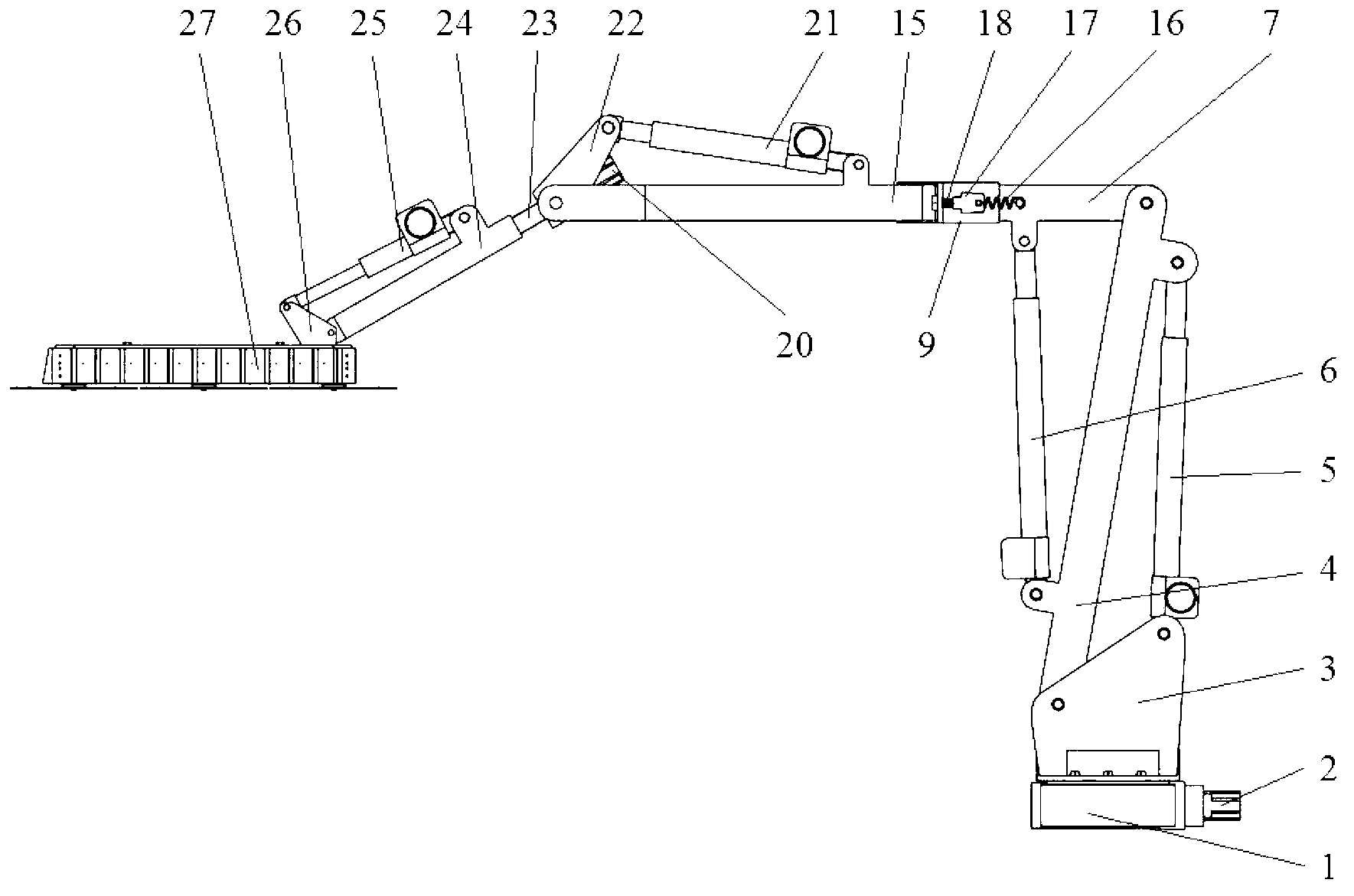

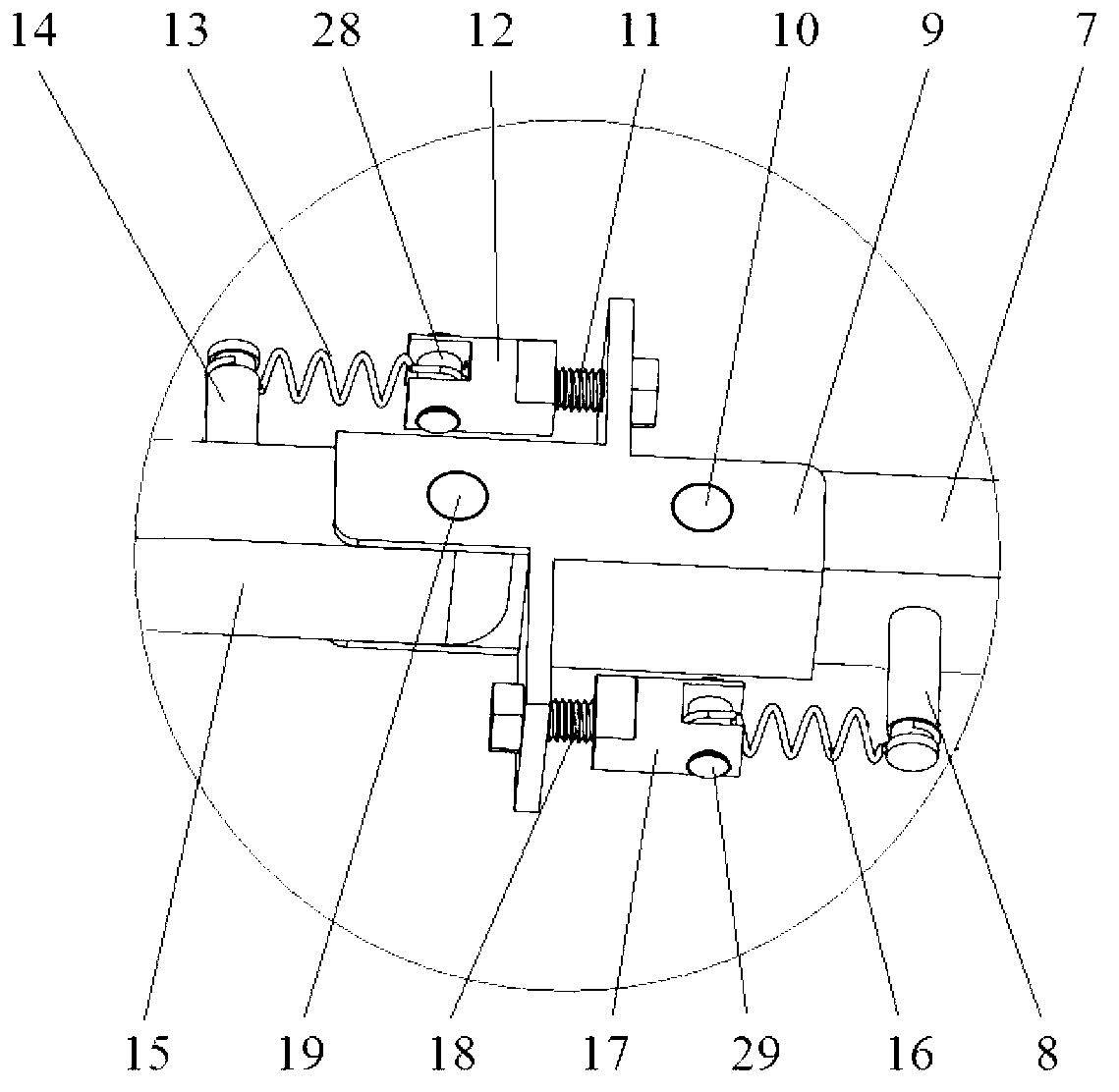

[0021] Refer to attached figure 1 and figure 2 , a rapidly reconfigurable multifunctional hedge seedling pruning manipulator, comprising a rotating chassis 1, a base 3, a large arm 4, a rear arm 7, a forearm 8, a small arm connecting frame 22, a small arm shaft 23, a small arm 24, a large Arm push rod 5, rear arm push rod 6 and forearm push rod 21, pruning cutter head adjustment push rod 25 also include overload protection mechanism and pruning cutter head 26, the specific connection mode is:

[0022] The rotating chassis 1 is fixedly installed on the carrier vehicle, the rotating chassis power motor 2 is installed on the rotating chassis 1, the base 3 is fixedly installed on the upper surface of the rotating chassis 1, the bottom end of the boom 4 is hinged with the base 3, and the boom 4 The upper end of the rear arm 7 is hinged with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com