Special full-value nutrient solution and organic substrate integrated cultivation mode for cucumber

A technology of organic substrate and cultivation mode, which is applied in the field of organic substrate integrated cultivation mode of cucumber special full-price nutrient solution, can solve the problems of continuous production of cucumber, imbalance of soil nutrient ratio, unreasonable fertilization ratio, etc., and achieve easy large-scale Popularization and application, safe fertilization, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Cucumber full price special nutrient solution, its nutrient content is as follows:

[0030] N: 210PPM

[0031] P: 35PPM

[0032] K: 320PPM

[0033] Ca: 150PPM

[0034] Mg: 42PPM

[0035] Fe: 3PPM

[0036] Mn: 1.5PM

[0037] B: 2.5PPM

[0038] Cu: 0.1PPM

[0039] Zn: 0.2PPM

[0040] Mo: 0.02PPM

[0041] The concentration of the above nutrient elements in the nutrient solution is converted into the actual requirements of various compounds, accurately weighed, and formulated into a concentrated nutrient solution. When it is necessary to fertilize cucumbers, dilute the above concentrated solution with water 100 times to the required concentration, and apply it to the cucumber root system by drip irrigation. The harmless treated edible fungus waste residue is used as the cultivation substrate. Planting in common soil was used as a control, and the amount of fertilizer applied was the same as that of the treatment.

Embodiment 2

[0042] Embodiment 2: Cucumber full price special nutrient solution, its nutrient content is as follows:

[0043] N: 200PPM

[0044] P: 32PPM

[0045] K: 265PPM

[0046] Ca: 140PPM

[0047] Mg: 35PPM

[0048] Fe: 5PPM

[0049] Mn: 4PM

[0050] B: 1.5PPM

[0051] Cu: 0.18PPM

[0052] Zn: 0.4PPM

[0053] Mo: 0.04PPM

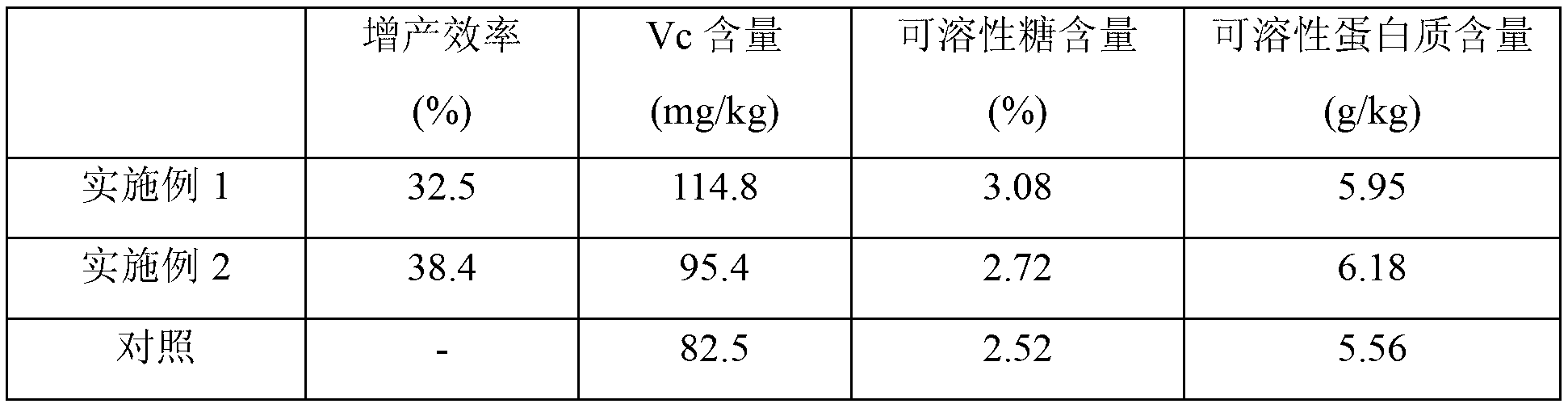

[0054] In the same greenhouse, use the cucumber-specific full-valent nutrient solution organic substrates prepared in Example 1 and Example 2, respectively, and apply the water-fertilizer integrated cultivation mode to plant cucumbers. At the same time, the traditional soil planting mode was used as a control, and the same variety was cultivated, and the total amount of nutrients applied was the same. Daily management measures are the same.

[0055] The application effect of above embodiment 1~2 and contrast is as follows:

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com