Balance pressurization type high efficiency digestion apparatus

A digestion device and high-efficiency technology, which are applied in the methods of chemically changing substances by using atmospheric pressure, the preparation of samples for testing, chemical instruments and methods, etc., to ensure system safety, ensure accuracy, and reduce experimental costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

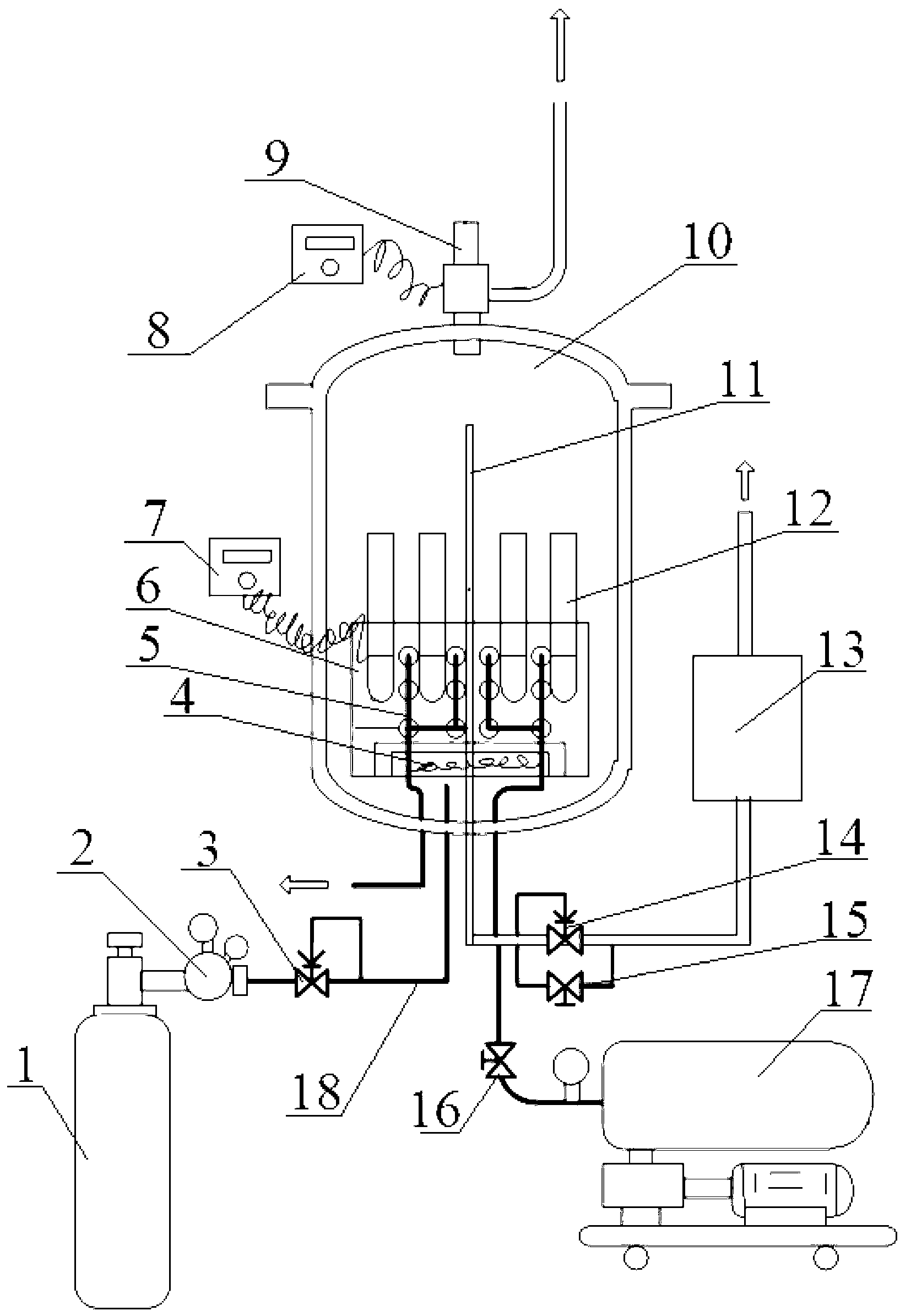

[0029] A balanced pressurized high-efficiency digestion device, such as figure 1 As shown, the device includes a pressure vessel 10, a pressurization unit, a heating block 6, a heating resistance wire 4, an air cooling pipeline 5, an air compressor 17, a sample tube 12, an air outlet pipe 11, a temperature sensing controller 7, a pressure Sensor 8; Wherein, the pressure vessel 10 is a sealed structure with a cover, the heating block 6 is an aluminum heating block, the pressurizing unit communicates with the pressure vessel 10, the heating block 6 is located in the pressure vessel 10, and the heating resistance wire 4 and the heating block 6 is connected to heat the heating block 6. The air cooling pipeline 5 is inserted inside the heating block 6 for cooling the heating block 6. One end of the air cooling pipeline 5 is connected to the air compressor 17 located outside the pressure vessel 10. The other end of the air cooling pipeline 5 extends to the outside of the pressure ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com