Method for preparing diethanol isopropanol amine

A technology of monoisopropanolamine and diethanolamine, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of aminohydroxy compounds, etc., can solve problems such as unsatisfactory strength of cement in the later stage, and achieves low cost, high yield, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

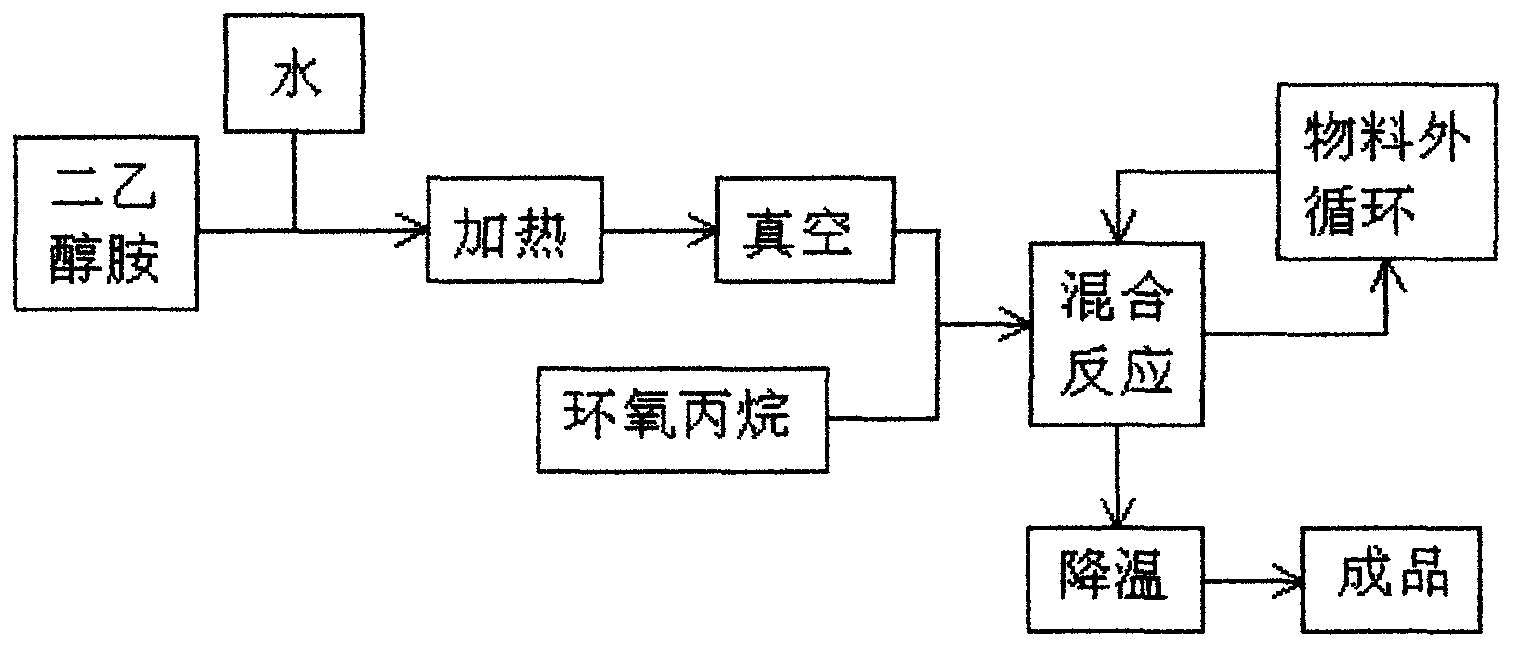

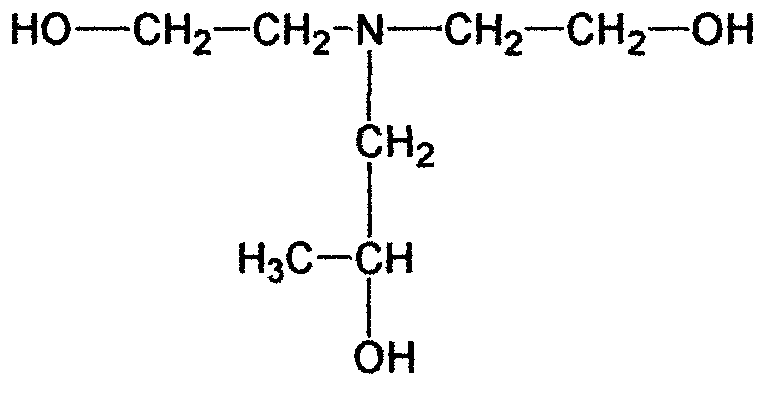

[0013] Refer to figure 1 with figure 2 As shown, a method for preparing diethanol monoisopropanolamine of the present invention, said diethanol monoisopropanolamine is obtained by mixing and reacting diethanolamine, propylene oxide and water in a reactor; its preparation steps as follows:

[0014] a) Add 142.0g of raw material diethanolamine into the reaction kettle, then add 30.2g of water, and mix and stir for 1 hour to obtain a mixture of diethanolamine and water.

[0015] b) Heat the reaction kettle to a temperature of 60°C, then vacuumize the reaction kettle, add 108.0g of raw material propylene oxide in proportion, and use an external circulation reaction kettle at a temperature of 60°C to carry out a cyclic reaction. The cyclic reaction is 2 hours to obtain two The yield of ethanol monoisopropanolamine and diethanol monoisopropanolamine was 96.6%.

[0016] c) After cooling down the diethanol monoisopropanolamine mixture obtained in step b), it is discharged and filled.

Embodiment 2

[0018] Refer to figure 1 with figure 2 As shown, a method for preparing diethanol monoisopropanolamine of the present invention, said diethanol monoisopropanolamine is obtained by mixing and reacting diethanolamine, propylene oxide and water in a reactor; its preparation steps as follows:

[0019] a) Add 220.5g of raw material diethanolamine into the reaction kettle, then add 31.5g of water, and mix and stir for 1.5 hours to obtain a mixture of diethanolamine and water.

[0020] b) Heat the reaction kettle to a temperature of 65°C, then vacuumize the reaction kettle, add 110.4g of raw material propylene oxide in proportion, and use an external circulation reaction kettle at a temperature of 65°C to carry out a cyclic reaction. The cyclic reaction is 4 hours to obtain two The yield of ethanol monoisopropanolamine and diethanol monoisopropanolamine was 97.6%.

[0021] c) After cooling down the diethanol monoisopropanolamine mixture obtained in step b), it is discharged and filled.

Embodiment 3

[0023] Refer to figure 1 with figure 2 As shown, a method for preparing diethanol monoisopropanolamine of the present invention, said diethanol monoisopropanolamine is obtained by mixing and reacting diethanolamine, propylene oxide and water in a reactor; its preparation steps as follows:

[0024] a) Add 284.0g of raw material diethanolamine into the reaction kettle, then add 32.5g of water, and mix and stir for 2 hours to obtain a mixture of diethanolamine and water.

[0025] b) Heat the reaction kettle to a temperature of 70°C, then vacuumize the reaction kettle, add 220.2g of propylene oxide as the raw material in proportion, and use an external circulation reactor at a temperature of 70°C. The yield of ethanol monoisopropanolamine and diethanol monoisopropanolamine was 98.8%.

[0026] c) After cooling down the diethanol monoisopropanolamine mixture obtained in step b), it is discharged and filled.

[0027] The beneficial effect of the preparation method of diethanol monoisoprop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com