Mobile drying tower system

A drying tower and cooling system technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of uneven dryness and wetness of grain, affecting grain quality, low drying degree, etc., and achieve good heat preservation effect, Easy to replace and dry thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

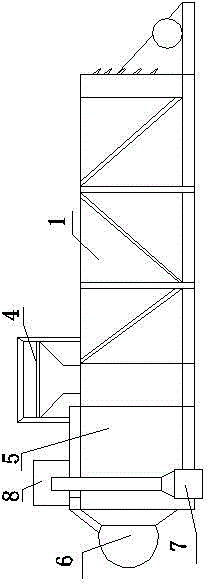

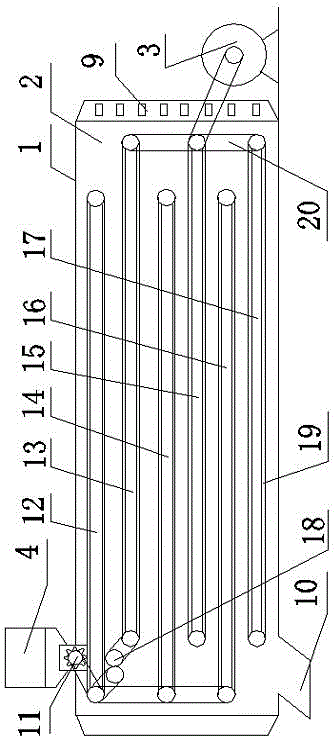

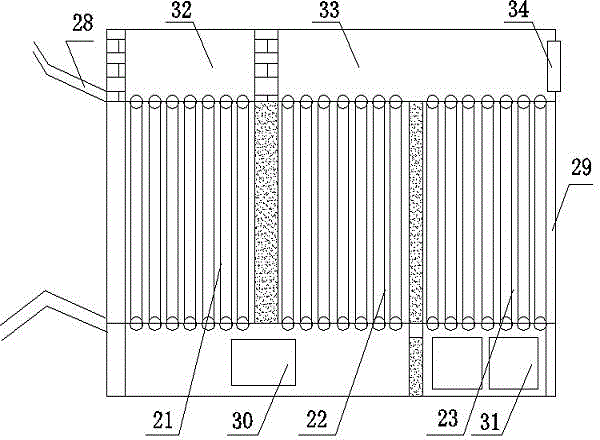

[0026] A mobile drying tower system, such as attached figure 1 , attached figure 2 As shown, its composition includes: an integral oven body 1, a mesh chain conveying cooling system 2 is installed in the integral oven body, and the mesh chain conveying cooling system is connected to an electromagnetic speed-regulating motor 3, and the mesh chain conveying cooling system is equipped with an advanced Hopper4. The body of the overall oven is 18000mm long and 2300mm wide, and the electromagnetic speed regulating motor is 7.5 kilowatts.

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that, as attached figure 1 As shown in the mobile drying tower system, the integral oven body is connected to the heat exchange system 5, the heat exchange system is connected to the hot air blower 6, the induced draft fan 7 and the hot blast boiler 8, and the heat exchange system is connected to the integral The feed hopper is provided between the ovens. The heat exchange system has a shell with a height of 3000mm and a length of 3758mm.

Embodiment 3

[0030] The difference between this embodiment and Embodiment 1 or Embodiment 2 is that, as attached figure 2 As shown, in the mobile drying tower system, the tail end of the integral oven body is connected to the tide outlet 9, and there are 6-10 tide outlets. The bottom of the integral oven body has a dry food output port 10, and the network chain An eight-blade pusher 11 is installed between the conveying cooling system and the hopper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com