Two-in-parallel parallel decoupling flexible microposition mechanism

A flexible mechanism and micro-positioning technology, applied in the mechanical field, can solve the problems of limiting the improvement of machining accuracy and quality, and low adjustment accuracy, and achieve the effects of compact structure, high resolution and fast dynamic response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

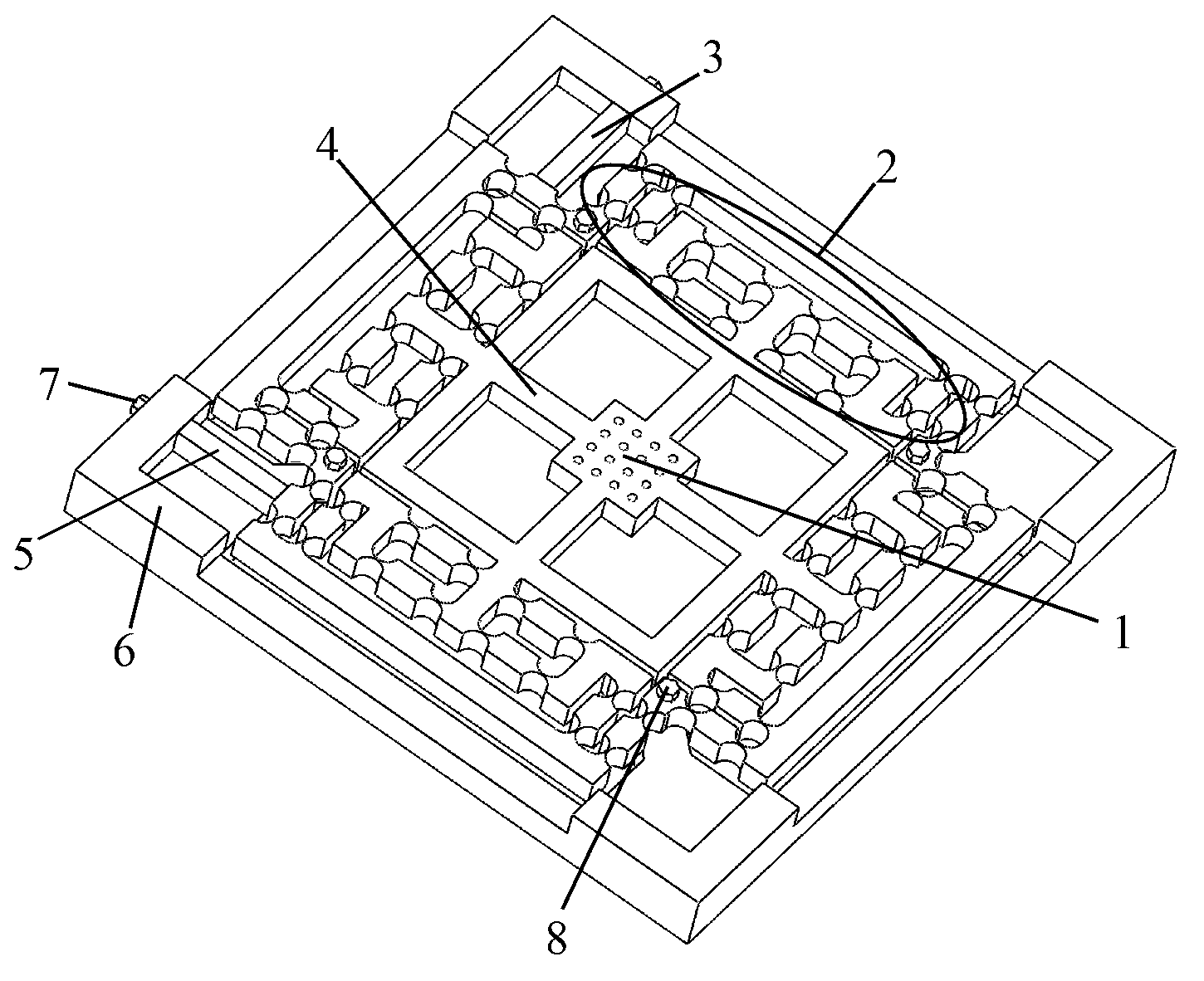

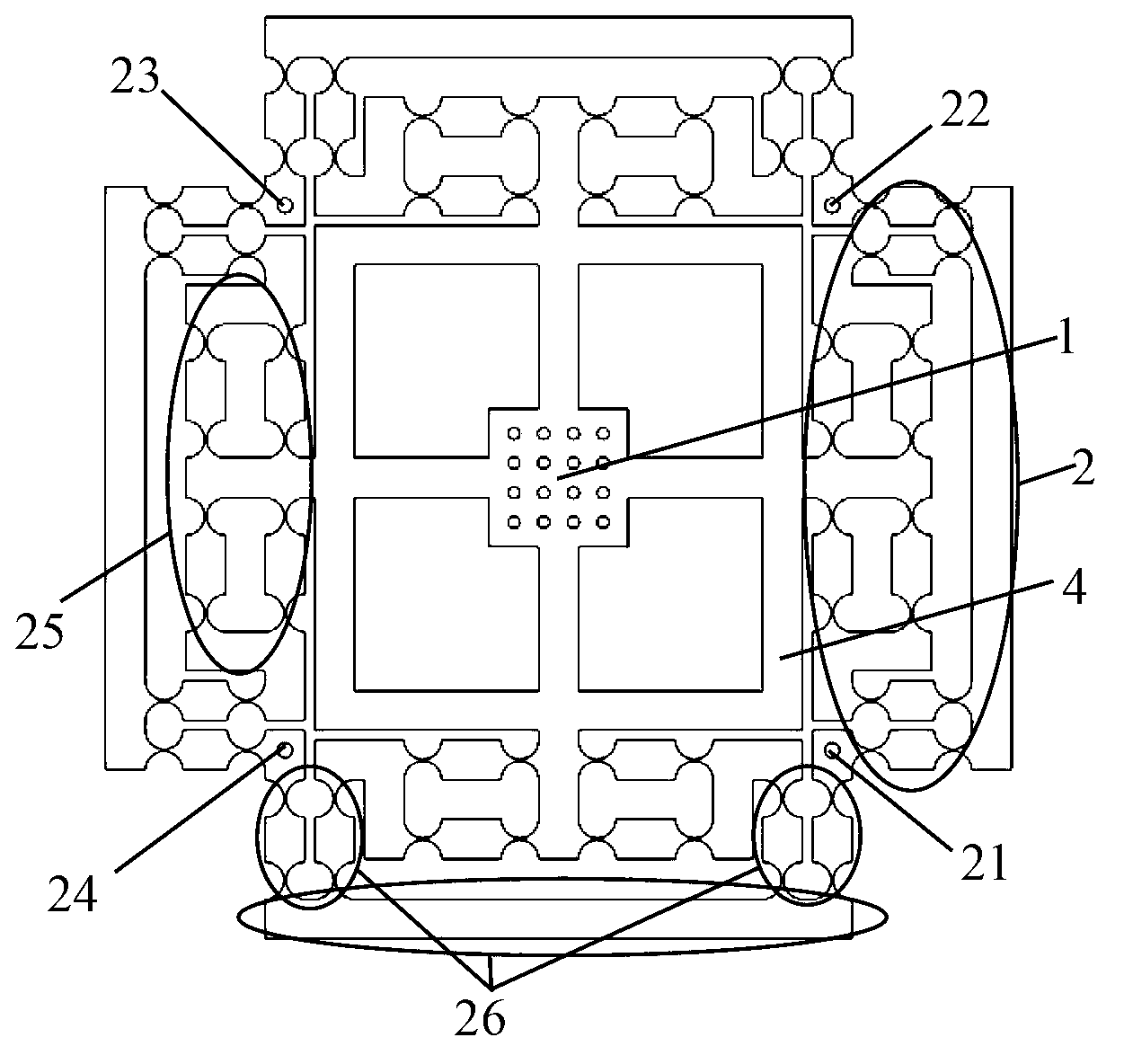

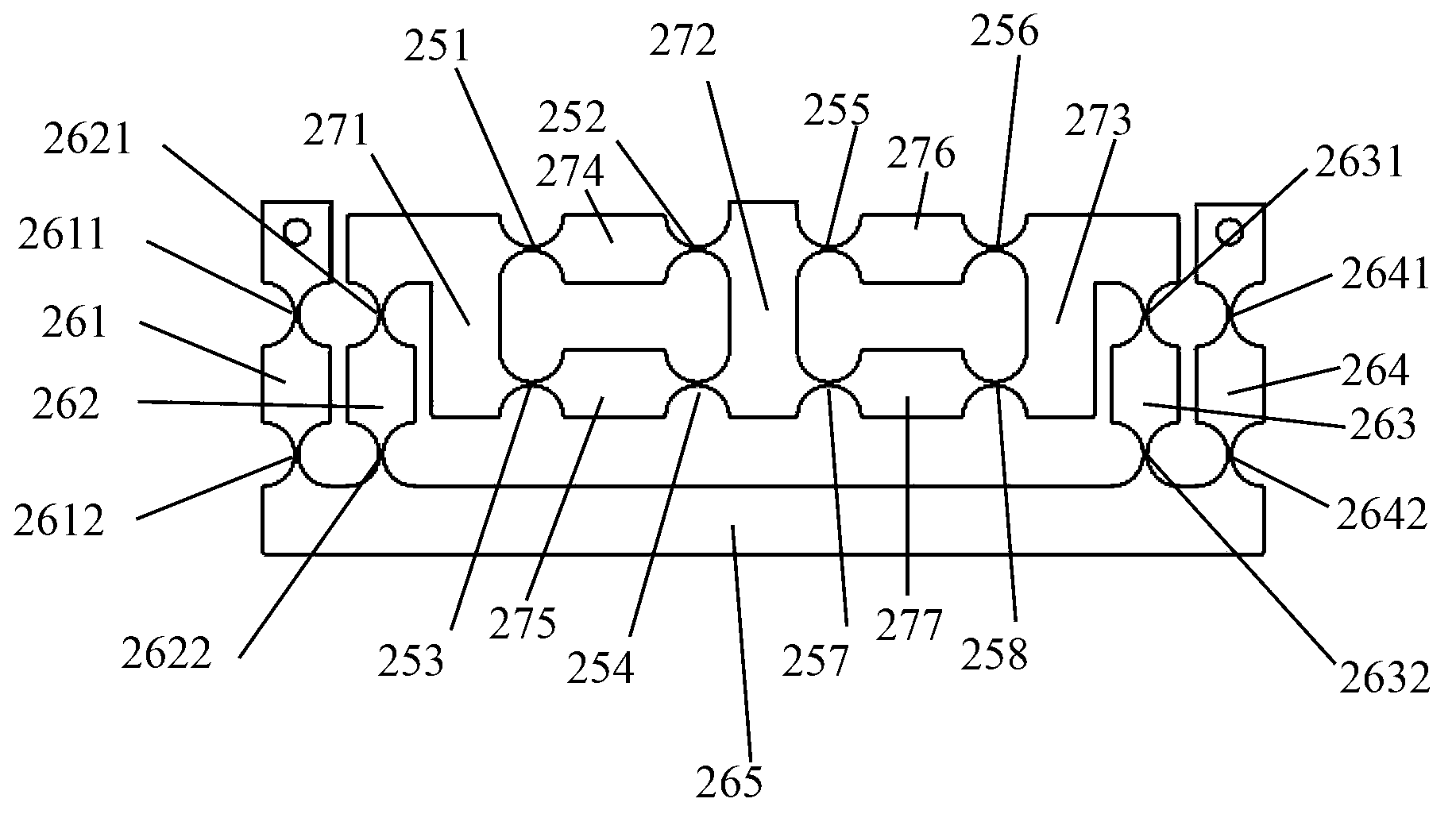

[0021] The double-parallel parallel decoupling flexible micro-positioning mechanism designed by the present invention (referred to as the positioning mechanism, see Figure 1-5 ), based on piezoelectric ceramic drive, characterized in that it includes a moving platform, four flexible branch chains, two piezoelectric ceramic drivers, a rigid support frame and a base; the moving platform is located at the center of the rigid support frame, The rigid support frame has a "Tian"-shaped structure and is used to support four flexible branch chains and their connected moving platforms; the four flexible branch chains are rectangular in design with the same structure and are evenly distributed on the four rigid sides of the rigid support frame. Each flexible branch chain is composed of inner and outer parts. The inner part is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com