tft-lcd array substrate and manufacturing method thereof, liquid crystal display

An array substrate and substrate technology, applied in the field of liquid crystal displays, can solve the problems of high production cycle and cost, and achieve the effects of reducing waste, increasing distance, and increasing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

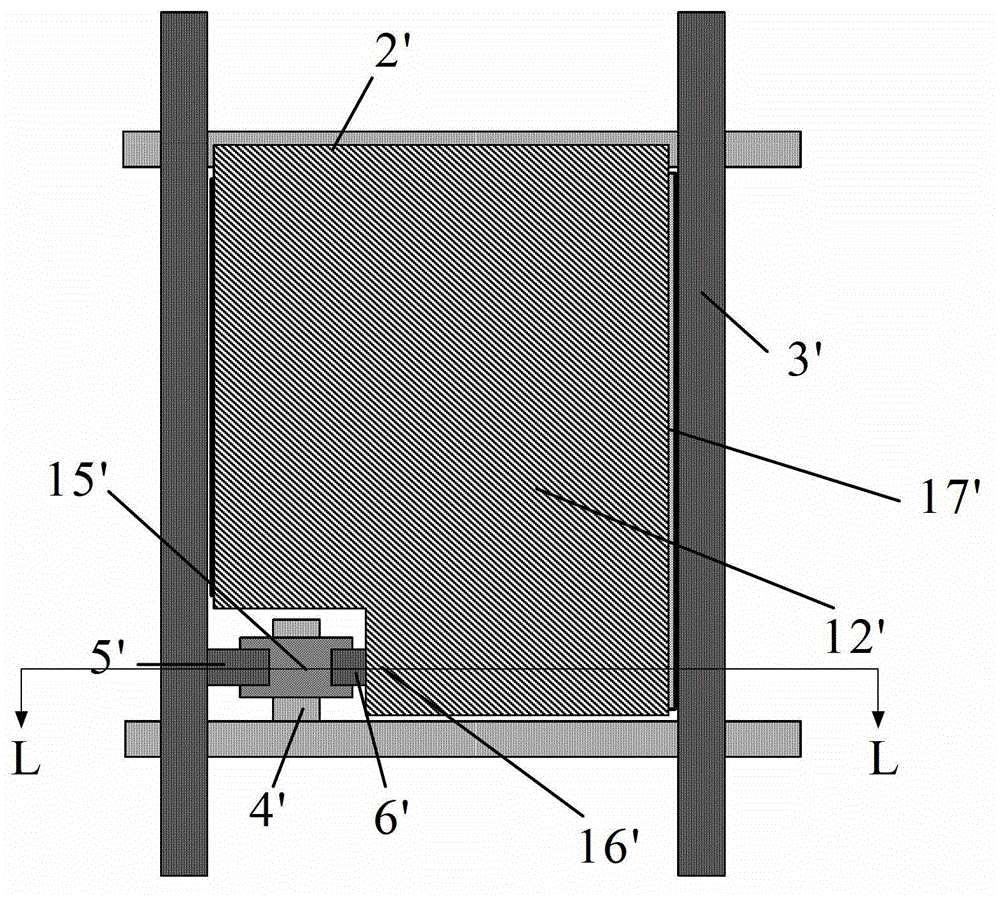

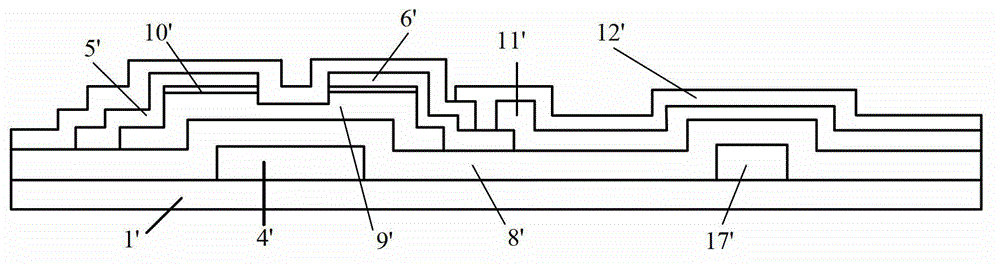

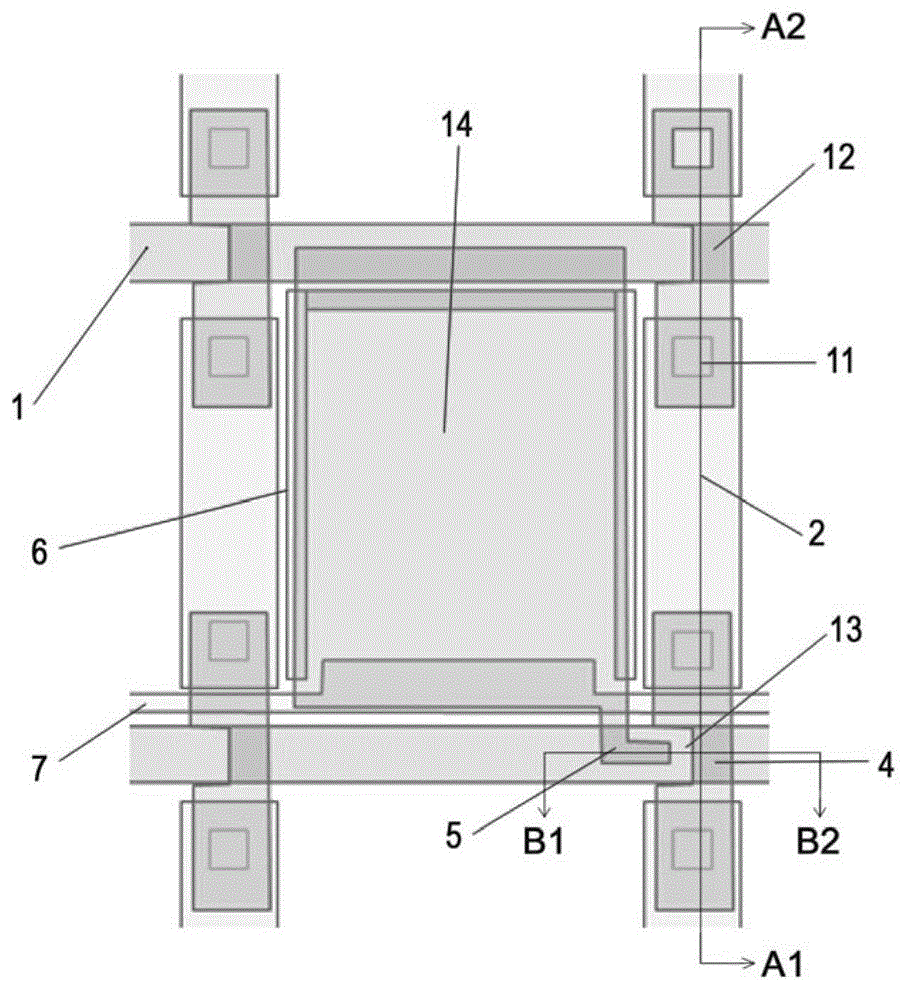

[0035] In order to make the content of the present invention clearer and easier to understand, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. In the present invention, the method for manufacturing a TFT-LCD array substrate proposed by the present invention and the TFT-LCD array substrate formed by the method are described by way of example, but the present invention is not limited to the specific forms of the disclosed preferred embodiments. Those skilled in the art can make modifications and variations to the present invention according to the content disclosed in the present invention, and these modifications and variations should also belong to the scope of protection of the present invention defined by the claims.

[0036] Aiming at the problems of long process cycle, high cost, low material utilization rate and large waste in the method of forming a TFT-LCD array substrate by four-time patterni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com