Resin molded product and process for producing same, resin composition and process for producing same, and electronic component device

A technology of resin molding and resin composition, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, electrical components, etc., can solve problems such as impracticality, reduce storage costs and transportation costs, and improve long-term Effects on storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

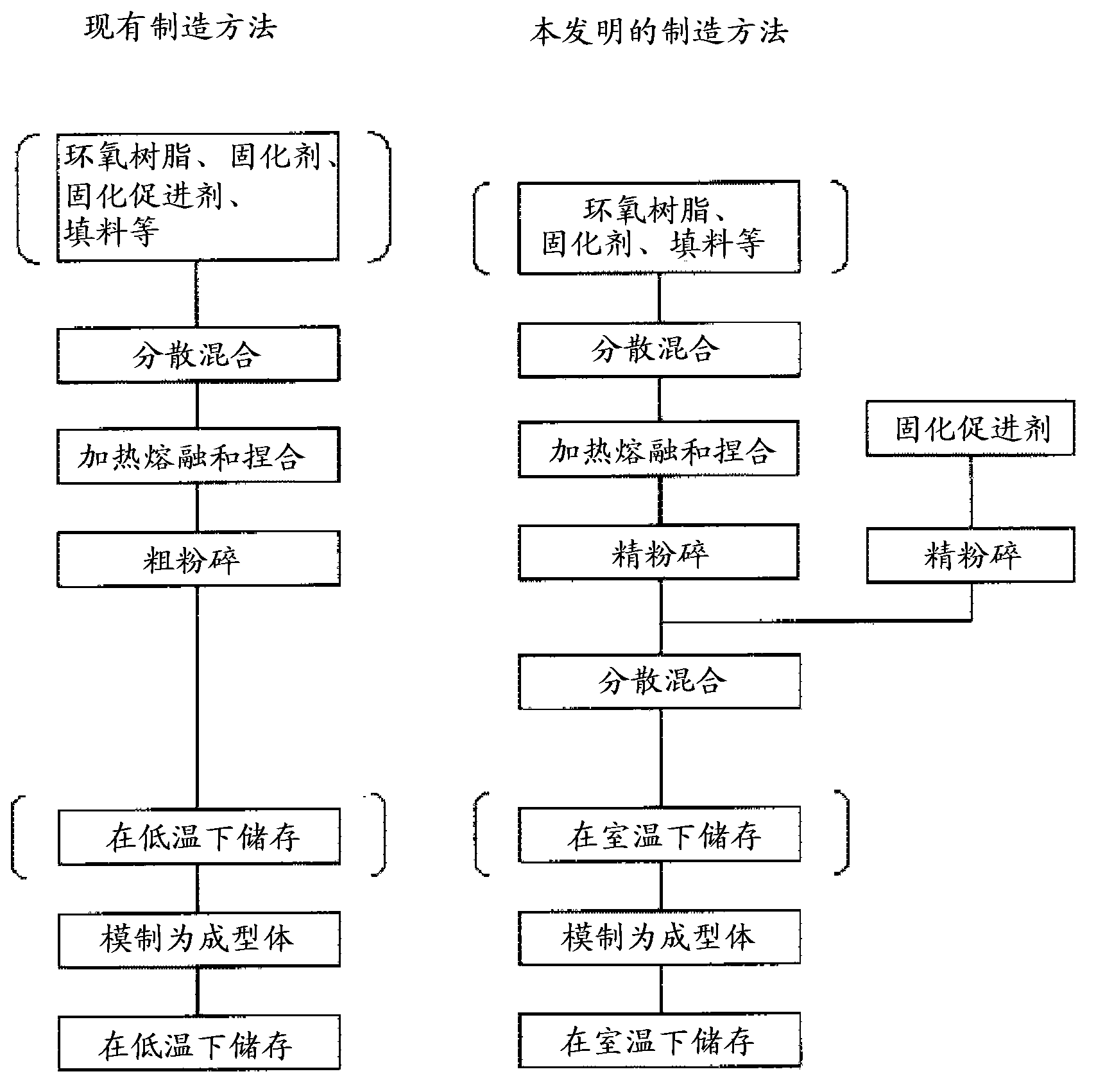

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0136] Hereinafter, although a description is given of embodiments (examples) of the present invention, the present invention is not limited thereto. In the following table, the value "composition ratio" described in the column is expressed in parts by weight.

[0137] A description will be given of raw materials used in Examples and Comparative Examples. Unless otherwise specified, each of the raw material, the first powder material, and the second powder material was measured using a laser-type particle size analyzer (SALD-7000 manufactured by Shimadzu Corporation) under the condition that the refractive index D was 1.70 to 1.00i particle size distribution.

[0138] (epoxy resin)

[0139] Epoxy resin 1: Epoxy resin 1 is a phenol aralkyl type epoxy resin having a biphenylene structure (by using a sample mill K manufactured by Fujipaudal Corporation II W-1. NC-3000 manufactured by Nipponkayaku Corporation finely pulverizes a phenol aralkyl type epoxy resin. The epoxy equiv...

Embodiment 1

[0164] Preparation of No. A powder material. Table 1 shows the median diameter of the prepared first powder material and the ratio of the amount of large-sized particles with a diameter equal to or greater than 500 μm relative to the total amount of particles of the prepared first powder material. Then, a resin composition was prepared by adding curing accelerator 2 to the prepared first powder material and performing dispersion and mixing for five minutes by using a propeller type mixer. Then, a resin sheet was obtained by molding the prepared resin composition into a sheet shape using a tablet machine (S-20A manufactured by Mitsubishi materials techno Corporation) under a pressure of 2 MPa. The obtained resin sheet had a degree of compression of 91%, a diameter of 18 mm, a height of 31.6 mm and a weight of 14.5 g. Table 1 shows the maximum temperature of the resin composition during dispersion and mixing and the maximum temperature of the resin sheet during molding of the ...

Embodiment 2

[0166] By mixing each of the components described in Table 1 below except curing accelerator 3 by using a propeller type mixer at room temperature, the mixture was melted and melted by using a heated drum at a temperature of 80° C. to 100° C. kneading, and then pulverizing the heated mixture using a pulverizer to prepare a first powder material. Table 1 shows the median diameter of the prepared first powder material and the ratio of the amount of large-sized particles with a diameter equal to or greater than 500 μm relative to the total amount of particles of the prepared first powder material. Then, a resin composition was prepared by adding curing accelerator 3 to the prepared first powder material and performing dispersion and mixing for five minutes by using a propeller type mixer. Then, a resin sheet was obtained by molding the prepared resin composition into a sheet shape using a tablet machine (S-20A manufactured by Mitsubishi materials techno Corporation) under a press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com