Magnetic pretreatment device for rolled emulsion

A pretreatment device and emulsion technology, applied in the field of metallurgy, can solve the problems of unsustainable slag scraping process, broken transmission chain, batch quality problems of zinc slag, etc., to reduce the work load, reduce equipment failure rate, and simple device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

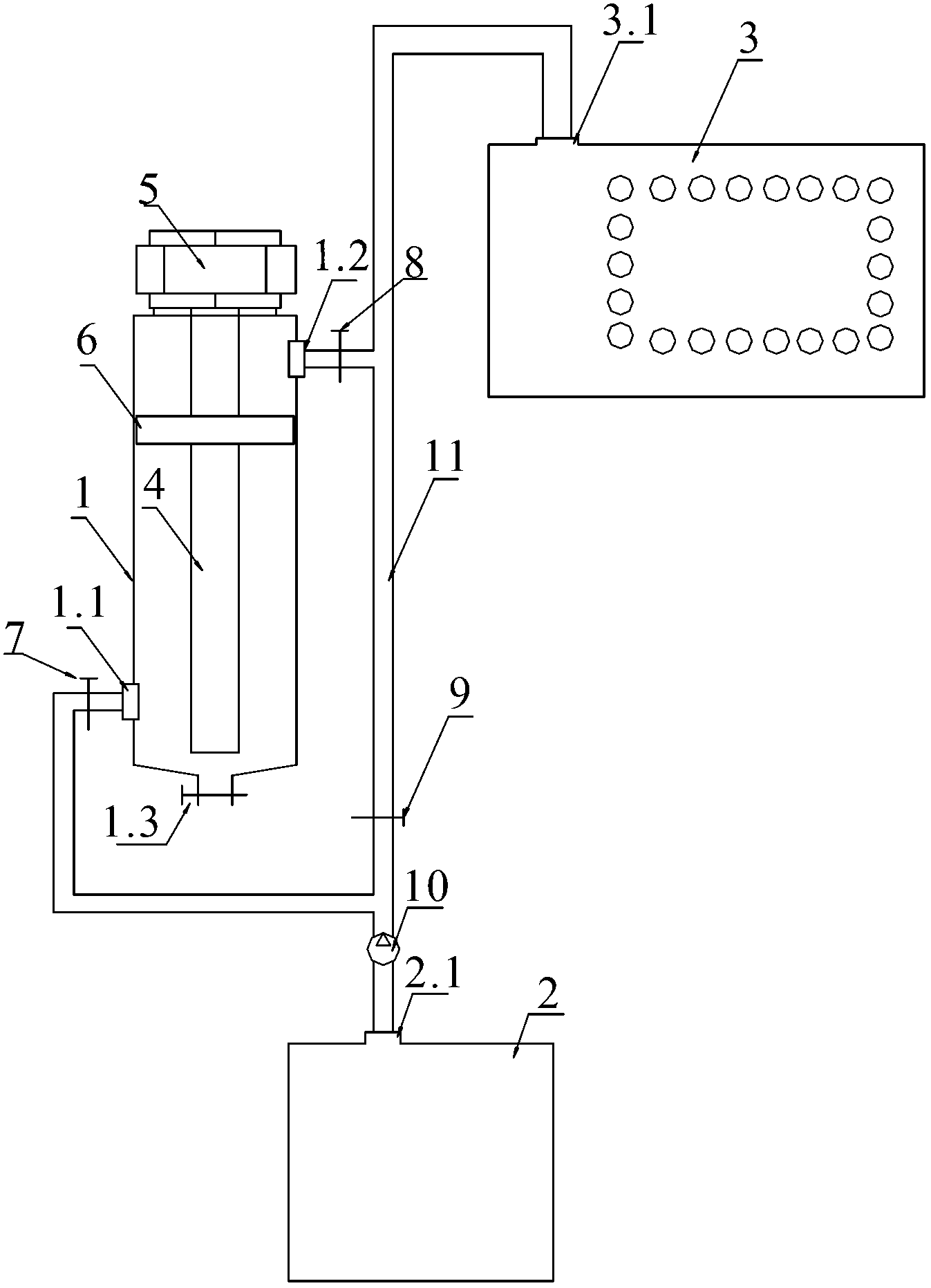

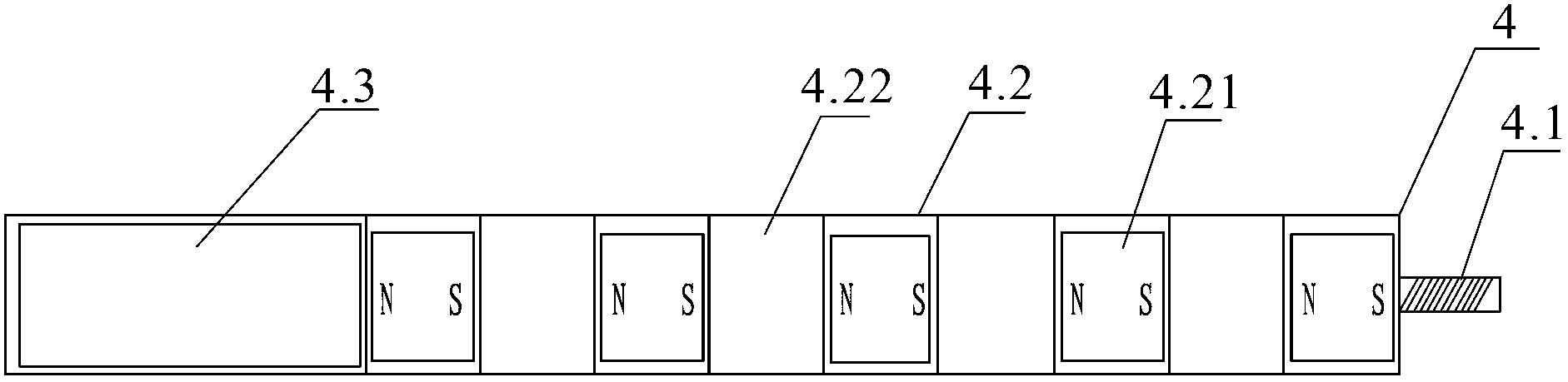

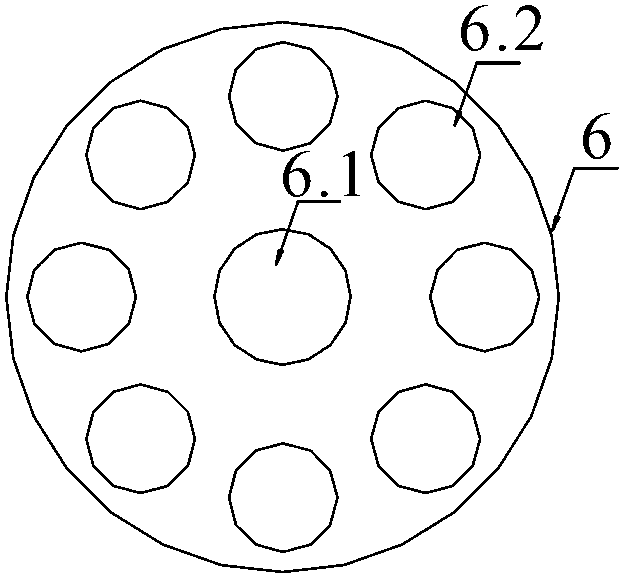

[0015] Figure 1~3 In the magnetic pretreatment device for emulsion after rolling, a set of magnetic pretreatment device is installed between the original magnetic chain filter device 3 and the emulsion recovery tank 2, and multiple sets of magnetic pretreatment device can be installed at the same time according to the processing capacity on site , To achieve parallel pre-separation of ferromagnetic materials. The magnetic pretreatment device for emulsion after rolling of the present invention includes a pretreatment tank 1 with a cylindrical structure. The top of the pretreatment tank 1 is provided with an opening, and a top cover 5 is screwed to the opening. It is in a sealed state during operation and the joint is installed. Sealing gasket to prevent liquid leakage. An adsorption magnet 4 extending to the bottom of the inner cavity of the pretre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com