Copper foil tin-soldering jag

A technology of soldering and jigs, which is applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of hidden dangers of workers' personal safety, injury of workers' fingers, and low efficiency, so as to achieve simple production processes, prevent injuries, and improve efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

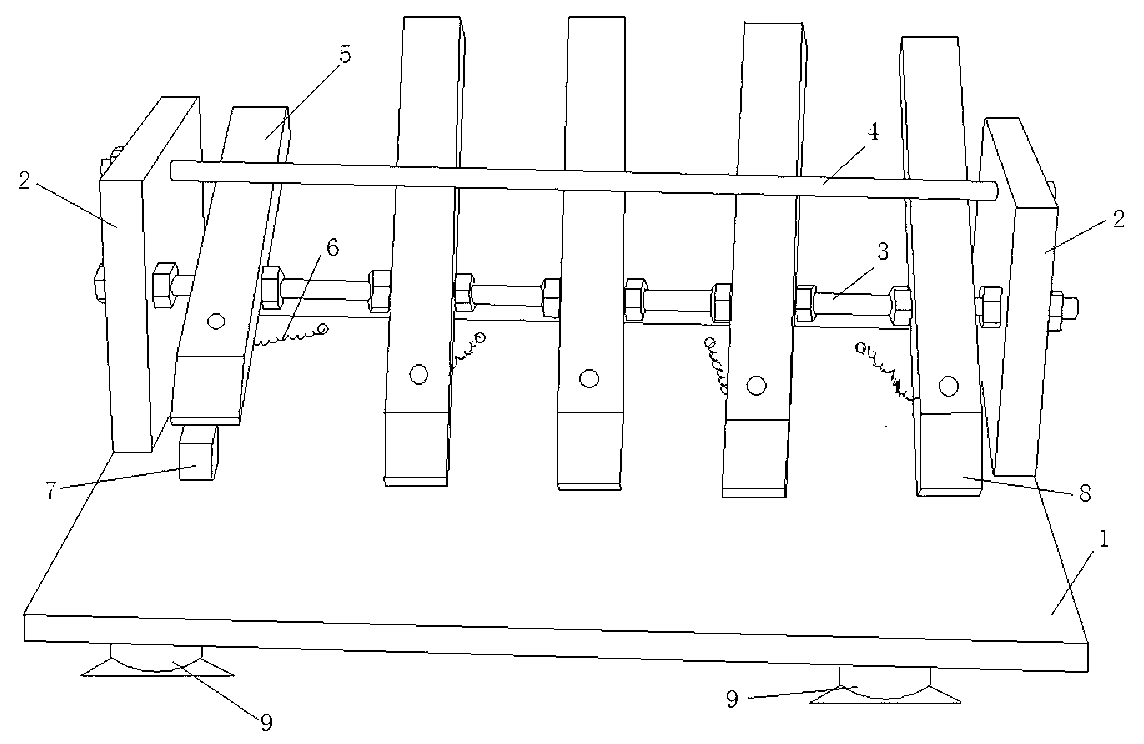

[0016] Such as figure 1 As shown, a copper foil soldering jig includes a base plate 1, a first cross bar 3 and at least one pressure bar 5, a baffle plate 2 is provided on both sides of the base plate 1, and the first cross bar 3 is fixed through the base plate 1. On the baffles 2 on both sides, the first crossbar 3 is fixed on the two baffles 2 through nuts, and the fixing effect is good. The first crossbar 3 is provided with a pressure bar 5, and the first crossbar 3 is provided with threads. Preferably, the pressure rods 5 are set to five, and each pressure rod 5 is fixed on the first cross bar 3 by a nut, and both sides of the pressure rod 5 are provided with nuts, which can not only ensure that the position of the pressure rod 5 does not shake, but also facilitate The pressure rod 5 rotates around the first cross bar 3 to press the transformer. The bottom plate 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap