Large-specification recombination composite structural wood and manufacturing method thereof

A composite structure and manufacturing method technology, applied in the field of construction and engineering structural materials, can solve the problems of decreased surface wettability, roughness, poor wettability, etc., and achieve the effect of improving the gluing performance and increasing the gluing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Large-scale finger-jointed recombined composite structural material

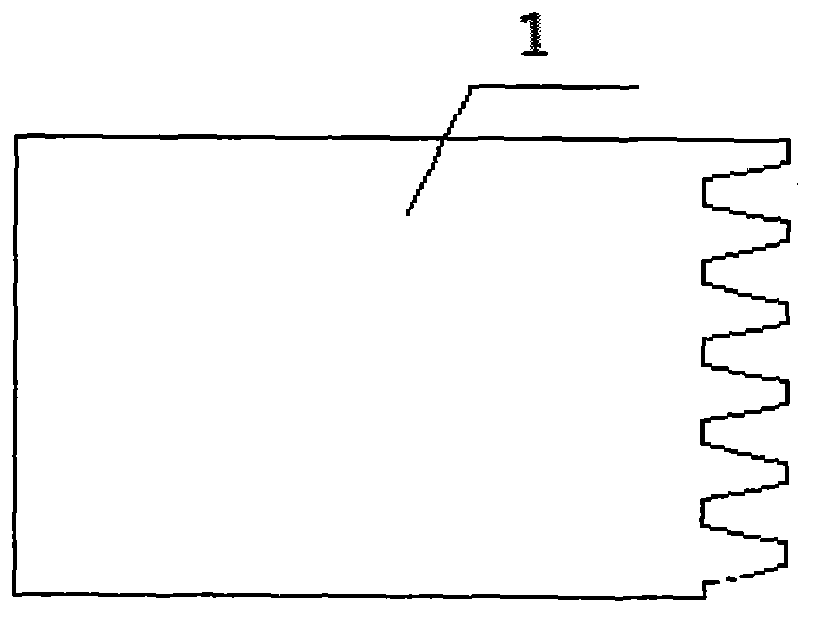

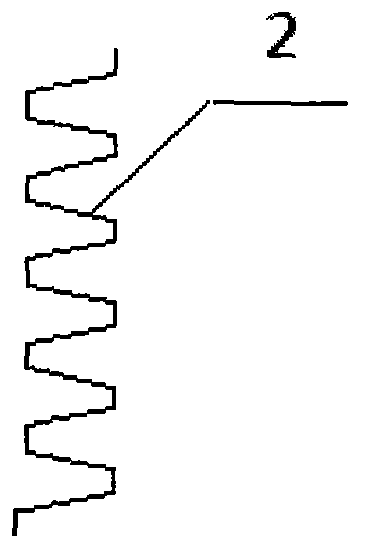

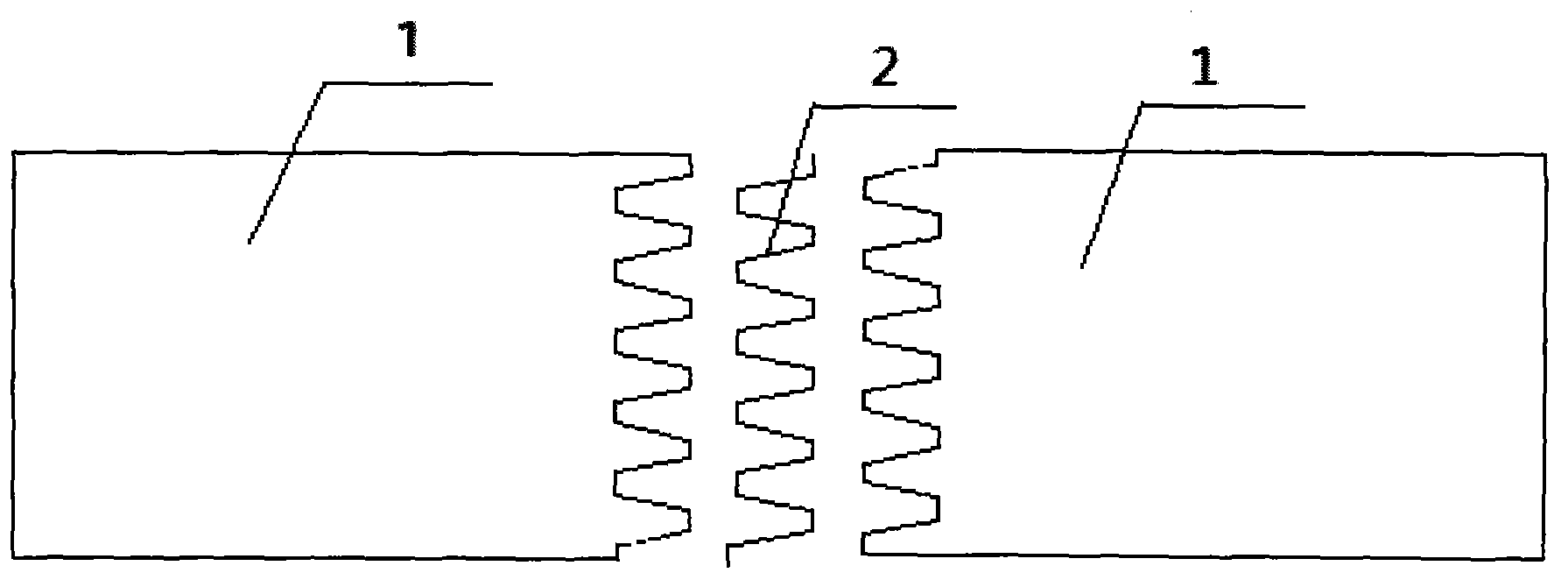

[0045] The large-scale recombined composite structural material of the typical embodiment of the present invention comprises recombined bamboo (1), wood veneer (2), cardboard (3) and adhesive (not marked in the figure), such as Figure 6 As shown, it is formed by stacking multiple layers of longitudinally finger-jointed restructured bamboo (1), and a layer of wood veneer (2) is arranged between each layer of restructured bamboo (1), and the thickness of the wood veneer is 1.2mm; There is an adhesive layer (not shown in the figure) between the bamboo and the wood veneer, and the adhesive used is resorcinol adhesive; the longitudinally elongated recombined bamboo is between the joint surfaces of the longitudinal finger joints A layer of cardboard (3) is provided, and an adhesive layer (not shown in the figure) is arranged between the reorganized bamboo (1) and the cardboard (3), and the adhes...

Embodiment 2

[0063] Example 2 Large-scale mitred recombined composite structural material

[0064] The large-scale recombined composite structural material of a typical embodiment of the present invention includes recombined wood (1), wood veneer (2), cardboard (3) and adhesive (not shown in the figure), such as Figure 11 As shown, it is formed by stacking multiple layers of recombined wood longitudinally mitred, and a layer of wood veneer (3) is arranged between each layer of recombined wood (1), and the thickness of the wood veneer is 0.8mm; the recombined wood (1 ) and the wood veneer (3) is provided with an adhesive layer (not shown in the figure), and the adhesive used is a water-based polymer isocyanate adhesive; A layer of cardboard (2) is arranged between the joint surfaces of longitudinal miter joints, and an adhesive layer (not shown in the figure) is arranged between the recombined wood (1) and the cardboard (2). The adhesive used is a water-based high Molecular isocyanate adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tooth length | aaaaa | aaaaa |

| Addendum width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com